Mortar agitator

A mixer and mortar technology, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as safety threats to on-site workers, and achieve the effects of improving construction safety, reducing obstacles, and reducing threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

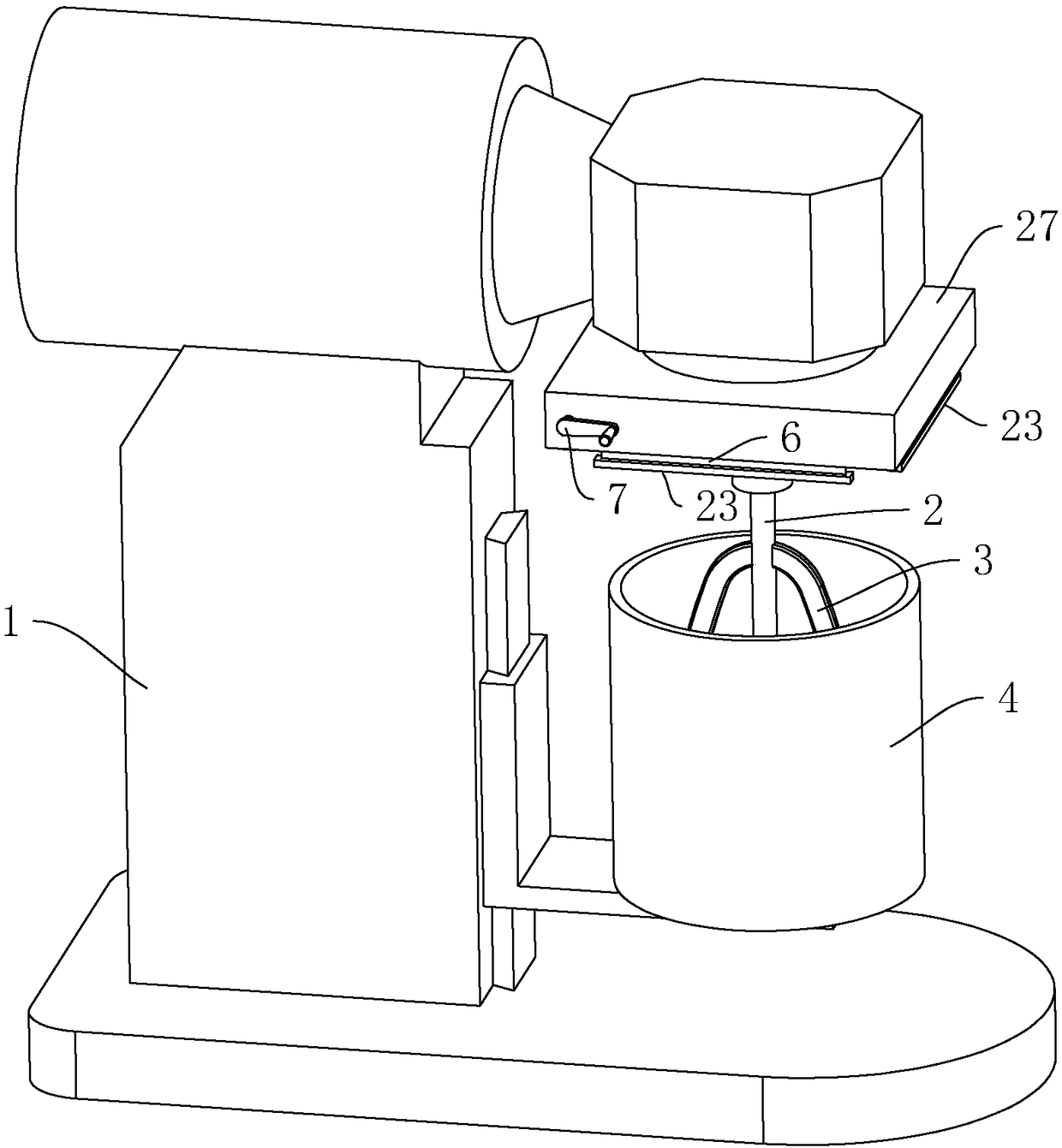

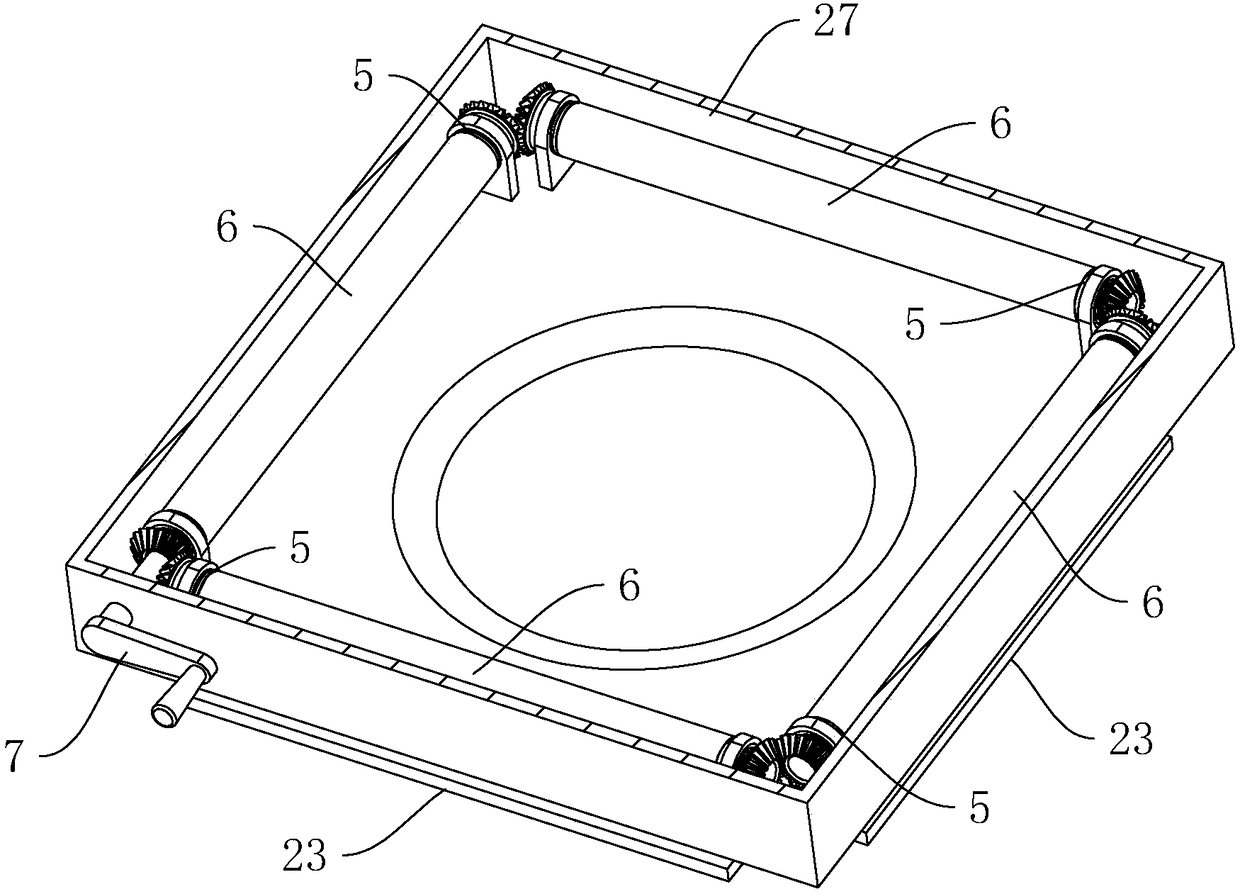

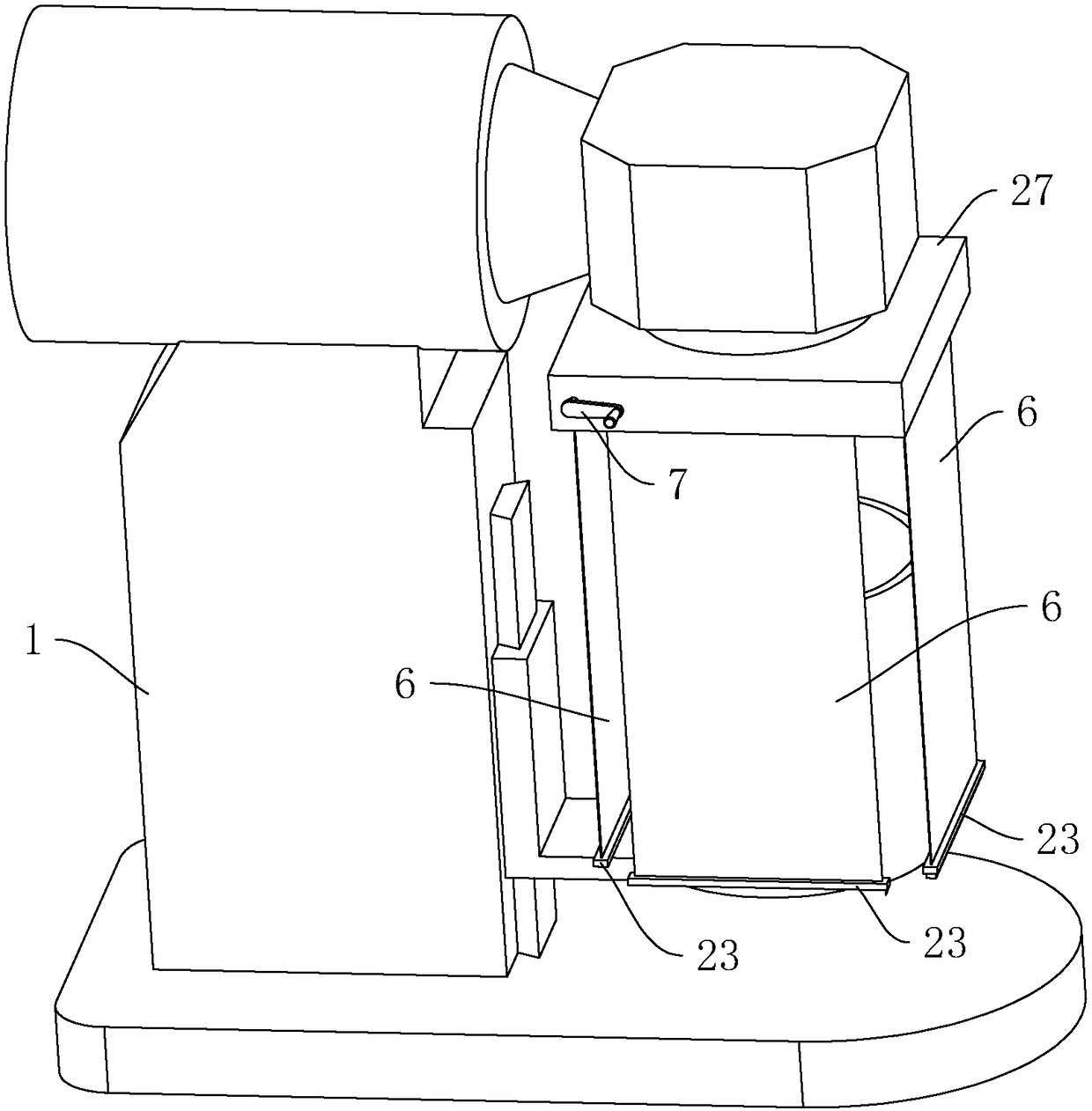

[0039] Example 1: Mortar Mixer, Combined figure 1 and figure 2 , including a fuselage 1, the fuselage 1 is fixedly connected with a rotating shaft 2 facing downwards, the rotating shaft 2 is provided with a stirring paddle 3, the fuselage 1 is provided with a stirring pot 4 below the rotating shaft 2, and the fuselage 1 is in A square installation box 27 is fixedly arranged above the mixing pot 4, and a rotating shaft 5 is arranged horizontally on each of the four inner sidewalls of the installation box 27. The rotating shaft 5 is wound with a curtain 6, and the rotating shaft 5 is connected with a driving member that drives its rotation. The adjacent rotating shafts 5 are driven by bevel gears, so that the adjacent rotating shafts 5 are linked with each other, and all the rotating shafts 5 can be driven by rotating one of the rotating shafts 5 by a driving member, thereby improving work efficiency.

[0040] The driving part is a hand crank 7, and the hand crank 7 is coaxial...

Embodiment 2

[0044] Example 2: Mortar mixer, combined with Figure 4 and Figure 5 , the difference from Embodiment 1 is that the driving part and the way of driving the driving part are different. In this embodiment, the driving part is a motor 8, and when the motor 8 rotates forward, the rotating shaft 5 rotates in the direction of putting down the curtain 6, instead of Manpower rotates the rotating shaft 5, and the work efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com