Water caltrop essence, preparation method and application thereof in cigarette

A technology of water chestnut and essence, which is applied in the direction of preparation of tobacco, application, essential oil/fragrance, etc., to achieve the effect of simple process, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

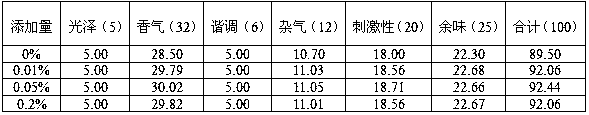

Image

Examples

Embodiment 1

[0025] A preparation method of water chestnut essence, it may further comprise the steps:

[0026] (1) Crushing and beating: choose mature water chestnut with high sugar content and high juice yield, cut the water chestnut pulp into slices with a thickness of 5-6mm with a knife, and beat the water chestnut slices with a high-speed tissue masher for 2 minutes at a speed of 11,000 rpm. Water chestnut pulp;

[0027] (2) Filtration under reduced pressure: filter the obtained water chestnut pulp under reduced pressure with a Buchner funnel, and collect the filtrate;

[0028] (3) Concentration under reduced pressure: Concentrate the filtrate under reduced pressure at 45°C and 55KPa to obtain concentrated water chestnut juice, and the dry matter content in the water chestnut concentrated juice is 30%;

[0029] (4) Maillard reaction: Add 30g of water chestnut juice concentrate, 10g of maltose, 10g of proline and 400g of propylene glycol in a 1000ml three-neck flask equipped with a re...

Embodiment 2

[0041] A preparation method of water chestnut essence, it may further comprise the steps:

[0042] (1) Crushing and beating: Select mature water chestnuts with high sugar content and high juice yield, cut the water chestnut pulp into slices with a thickness of 5-6mm with a knife, and beat the water chestnut slices with a high-speed tissue masher for 15 minutes at a speed of 12000 rpm. Water chestnut pulp;

[0043] (2) Filtration under reduced pressure: filter the obtained water chestnut pulp under reduced pressure with a Buchner funnel, and collect the filtrate;

[0044] (3) Concentration under reduced pressure: Concentrate the filtrate under reduced pressure at 60°C and 65KPa to obtain concentrated water chestnut juice, and the dry matter content in the water chestnut concentrated juice is 25%;

[0045] (4) Maillard reaction: Add 40g of water chestnut juice concentrate, 10g of honey, 10g of glycine and 400g of propylene glycol in a 1000ml three-neck flask equipped with a ref...

Embodiment 3

[0054] A preparation method of water chestnut essence, it may further comprise the steps:

[0055] (1) Crushing and beating: choose mature water chestnut with high sugar content and high juice yield, cut the water chestnut pulp into slices with a thickness of 5-6 mm with a knife, and beat the water chestnut slices with a high-speed tissue masher for 20 minutes at a speed of 10,000 rpm. Water chestnut pulp;

[0056] (2) Filtration under reduced pressure: filter the obtained water chestnut pulp under reduced pressure with a Buchner funnel, and collect the filtrate;

[0057] (3) Concentration under reduced pressure: Concentrate the filtrate under reduced pressure at 40°C and 70KPa to obtain concentrated water chestnut juice, and the dry matter content in the water chestnut concentrated juice is 35%;

[0058] (4) Maillard reaction: Add 30g of water chestnut juice concentrate, 10g of malt extract, 5g of alanine and 350g of propylene glycol in a 1000ml three-neck flask equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com