Rapid washing device for rare earth oxalate

A washing device and oxalate technology, applied in the direction of improving process efficiency, etc., can solve the problems of slow replacement of filter washing parts and inability to quickly wash rare earth oxalate, and achieve safe and reliable performance, stable operation, and precise rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

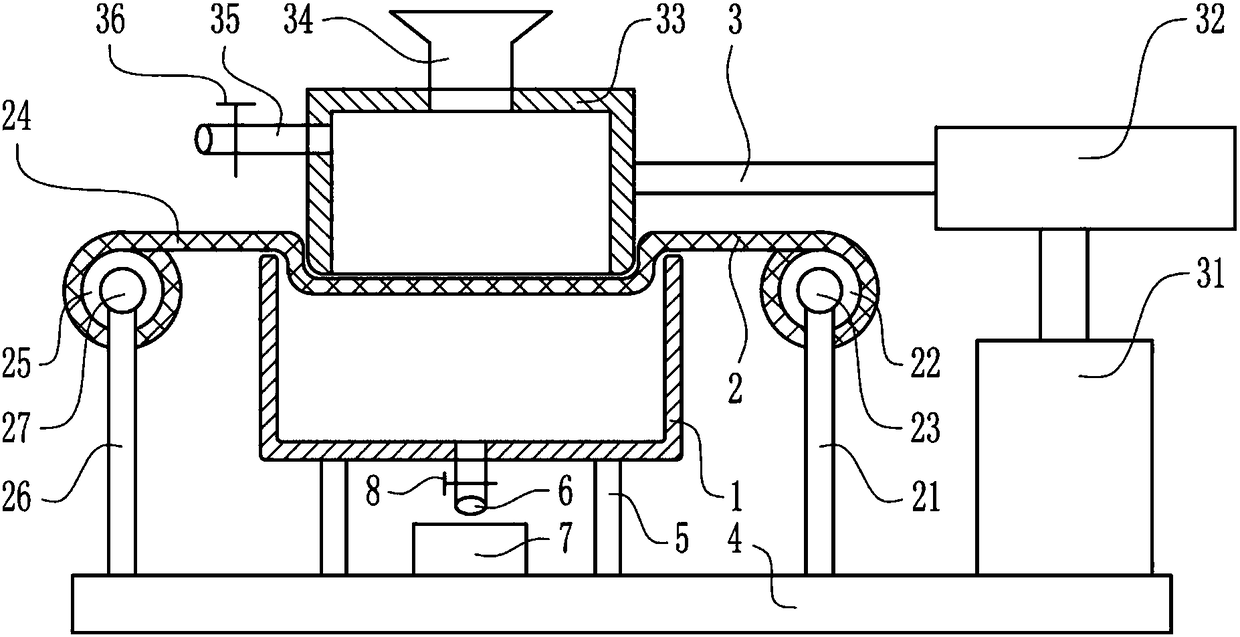

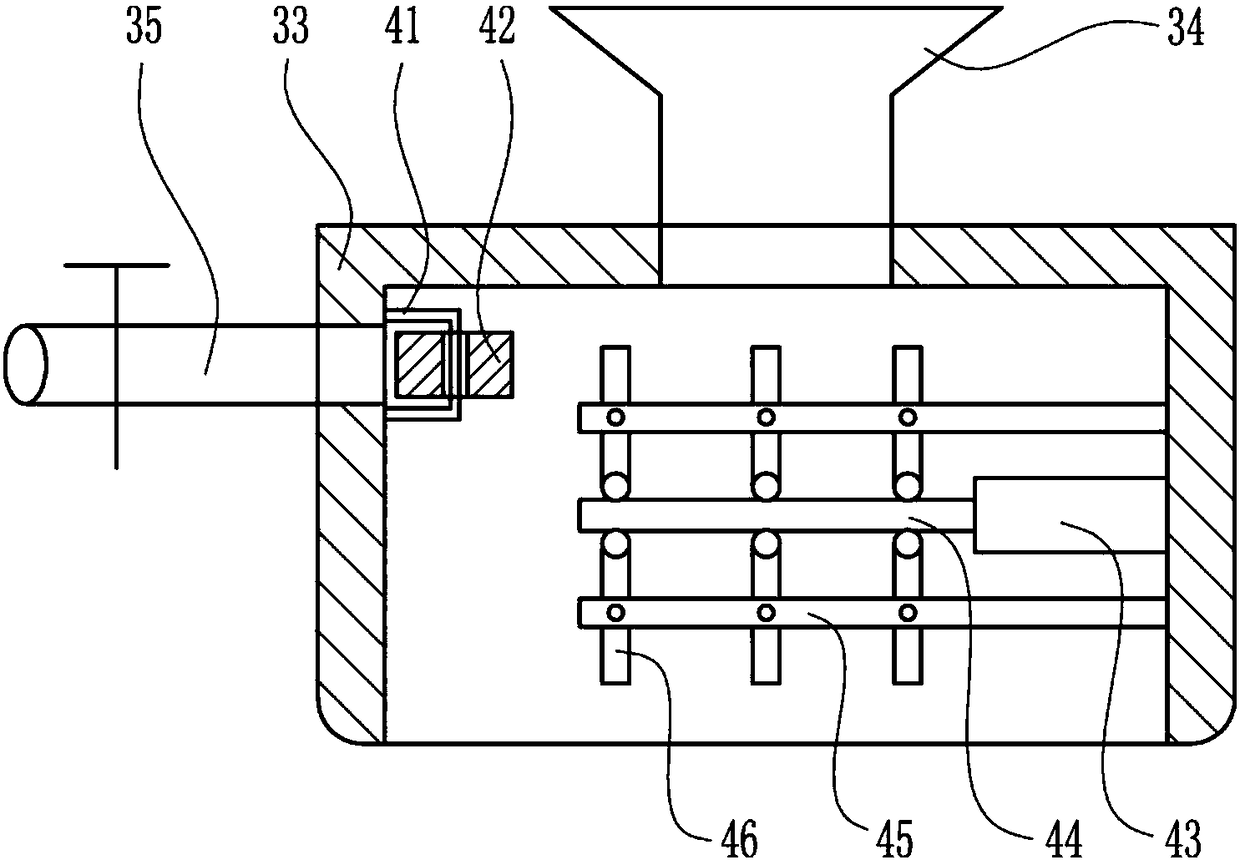

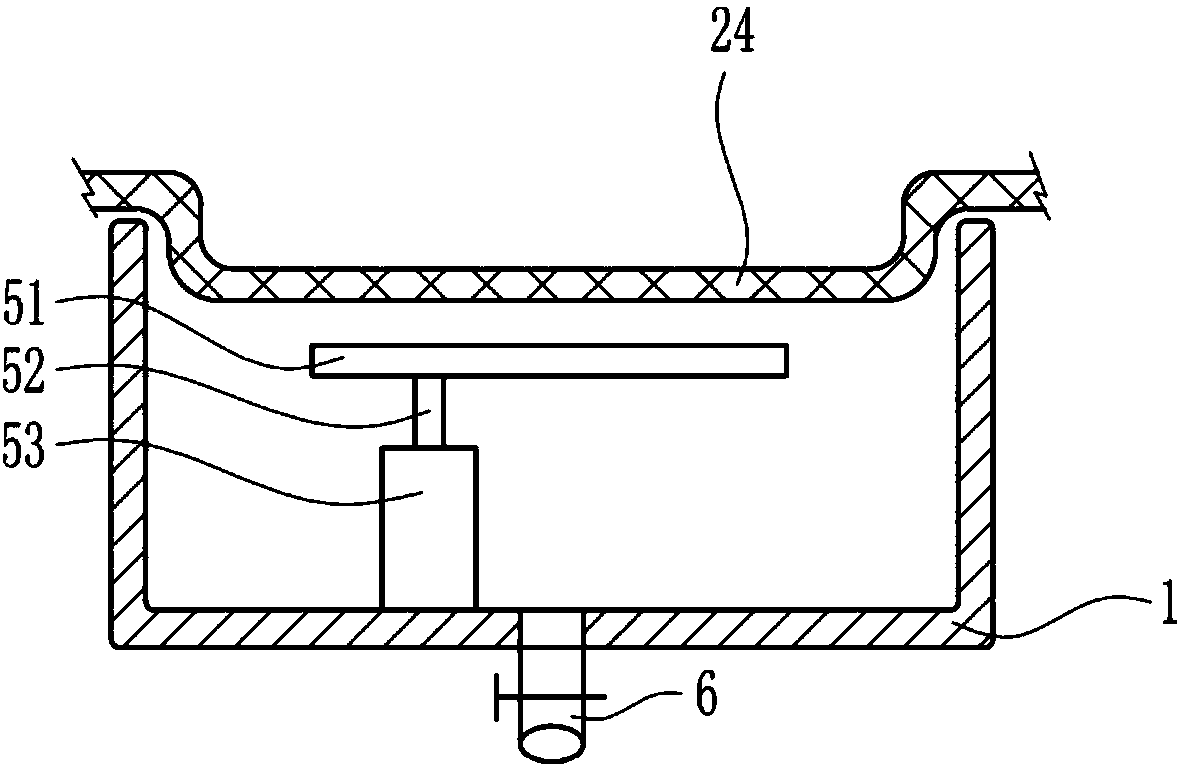

[0027] A quick washing device for rare earth oxalates, such as Figure 1-3As shown, it includes a cylinder 1, a filter device 2, a feed liquid device 3, a base 4, a leg 5, a liquid outlet pipe 6, a liquid receiving cylinder 7 and a valve I8; the top of the cylinder 1 is connected to the filter device 2 , the filter device 2 is connected with the feed liquid device 3, the feed liquid device 3 and the filter device 2 are both arranged above the base 4, and the left and right sides of the cylinder body 1 are symmetrically provided with legs 5, and the upper ends of the legs 5 are connected to the The bottom of the cylinder body 1 is connected by welding, the lower end of the leg 5 is connected to the top of the base 4 by welding, the liquid outlet pipe 6 is located between the left and right symmetrically arranged legs 5, and the upper end of the liquid outlet pipe 6 is connected to the top of the base 4 by welding. The middle part of the bottom of the cylinder body 1 is connecte...

Embodiment 2

[0029] A quick washing device for rare earth oxalates, such as Figure 1-3 As shown, it includes a cylinder 1, a filter device 2, a feed liquid device 3, a base 4, a leg 5, a liquid outlet pipe 6, a liquid receiving cylinder 7 and a valve I8; the top of the cylinder 1 is connected to the filter device 2 , the filter device 2 is connected with the feed liquid device 3, the feed liquid device 3 and the filter device 2 are both arranged above the base 4, and the left and right sides of the cylinder body 1 are symmetrically provided with legs 5, and the upper ends of the legs 5 are connected to the The bottom of the cylinder body 1 is connected by welding, the lower end of the leg 5 is connected to the top of the base 4 by welding, the liquid outlet pipe 6 is located between the left and right symmetrically arranged legs 5, and the upper end of the liquid outlet pipe 6 is connected to the top of the base 4 by welding. The middle part of the bottom of the cylinder body 1 is connect...

Embodiment 3

[0032] A quick washing device for rare earth oxalates, such as Figure 1-3 As shown, it includes a cylinder 1, a filter device 2, a feed liquid device 3, a base 4, a leg 5, a liquid outlet pipe 6, a liquid receiving cylinder 7 and a valve I8; the top of the cylinder 1 is connected to the filter device 2 , the filter device 2 is connected with the feed liquid device 3, the feed liquid device 3 and the filter device 2 are both arranged above the base 4, and the left and right sides of the cylinder body 1 are symmetrically provided with legs 5, and the upper ends of the legs 5 are connected to the The bottom of the cylinder body 1 is connected by welding, the lower end of the leg 5 is connected to the top of the base 4 by welding, the liquid outlet pipe 6 is located between the left and right symmetrically arranged legs 5, and the upper end of the liquid outlet pipe 6 is connected to the top of the base 4 by welding. The middle part of the bottom of the cylinder body 1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com