Fiber recycling and treating device and method of used clothes

A recycling and processing device technology, which is applied in the field of clothing manufacturing, can solve the problems of fiber filament winding and difficult removal of fiber filament, etc., and achieve the effect of convenient replacement and maintenance, and simple disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

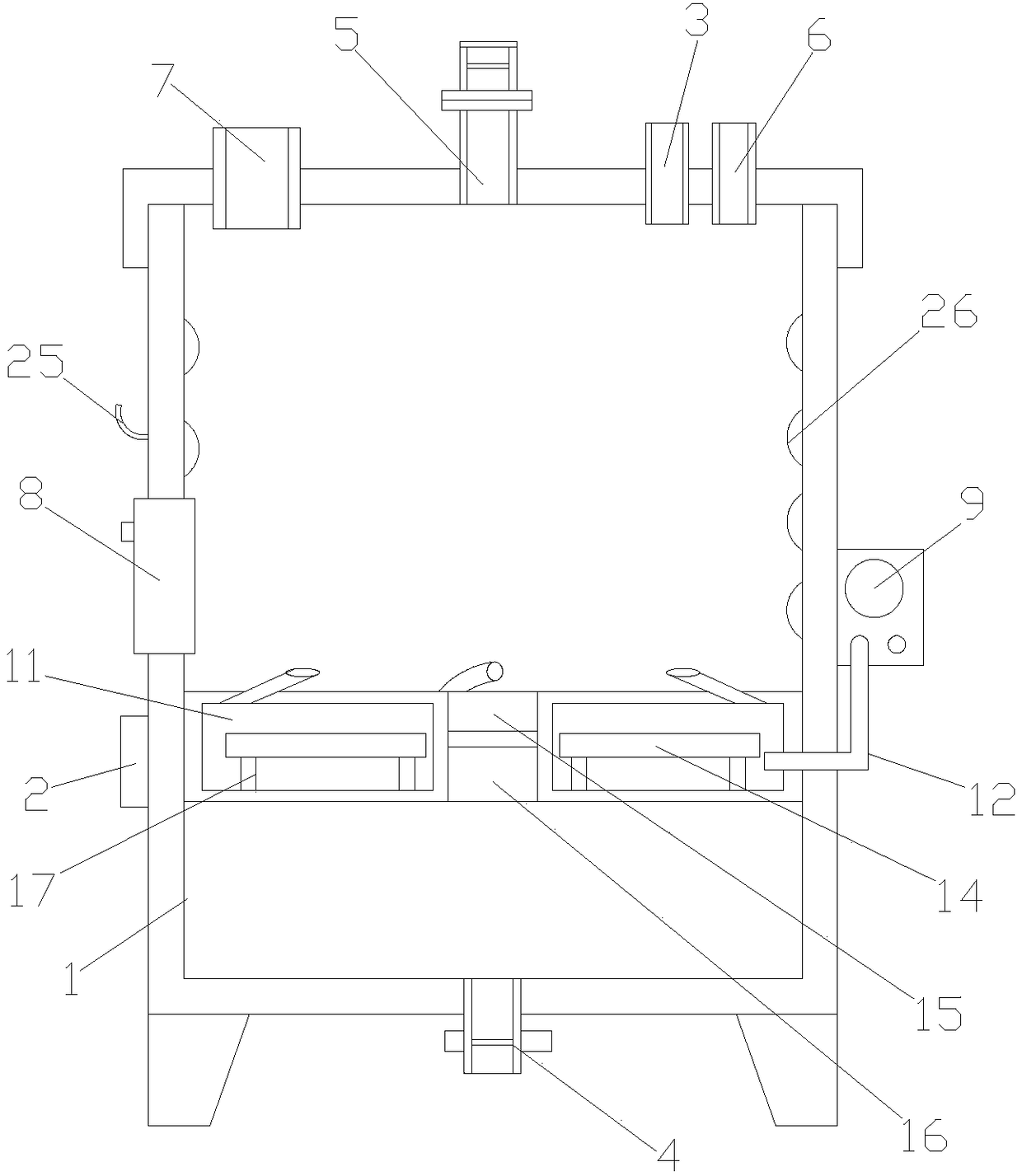

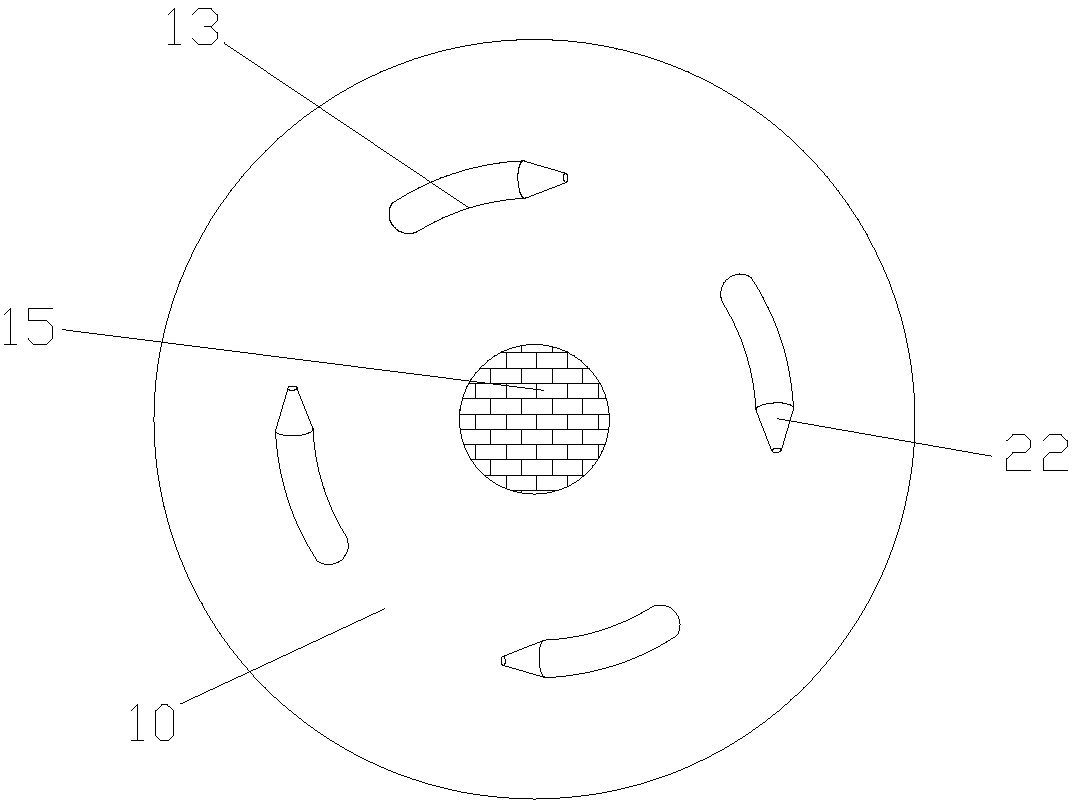

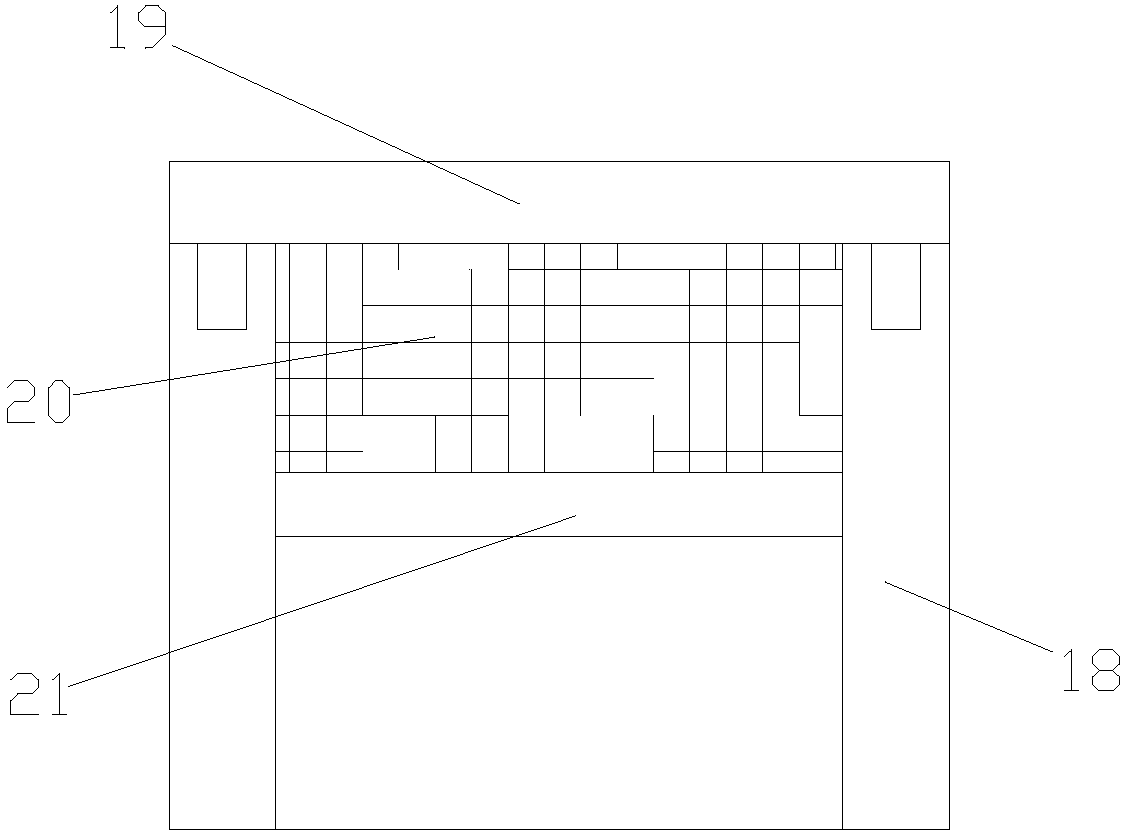

[0031] Such as Figure 1-2As shown, a fiber recycling treatment device for used clothes includes a tank body 1 and a control device 2, and the tank body 1 is provided with a water inlet pipe 3, a drain pipe 4, an exhaust pipe 5, a medicine feeding pipe 6 and The discharge pipe 7, the side of the tank body 1 is provided with a material taking hole (not shown), the said material taking hole is equipped with a detachable observation window 8, the side of the said tank body 1 is provided with a pump body 9, said tank body 1 A carrier plate 10 is arranged inside the body 1, and an annular air chamber 11 is arranged inside the carrier plate 10. The exhaust nozzle of the pump body 9 is connected with an exhaust pipe 12, and the exhaust pipe 12 runs through the tank body 1 and the The carrier plate 10 is provided, the end of the exhaust pipe 12 is located in the annular air chamber 11, the exhaust pipe 12 communicates with the annular air chamber 11, and the carrier plate 10 is provid...

Embodiment 2

[0034] Such as Figure 1-4 As shown, a fiber recycling treatment device for used clothes includes a tank body 1 and a control device 2, and the tank body 1 is provided with a water inlet pipe 3, a drain pipe 4, an exhaust pipe 5, a medicine feeding pipe 6 and The discharge pipe 7, the side of the tank body 1 is provided with a material taking hole (not shown), the said material taking hole is equipped with a detachable observation window 8, the side of the said tank body 1 is provided with a pump body 9, said tank body 1 A carrier plate 10 is arranged inside the body 1, and an annular air chamber 11 is arranged inside the carrier plate 10. The exhaust nozzle of the pump body 9 is connected with an exhaust pipe 12, and the exhaust pipe 12 runs through the tank body 1 and the The carrier plate 10 is provided, the end of the exhaust pipe 12 is located in the annular air chamber 11, the exhaust pipe 12 communicates with the annular air chamber 11, and the carrier plate 10 is provi...

Embodiment 3

[0037] Such as Figure 1-4 As shown, a fiber recycling treatment device for used clothes includes a tank body 1 and a control device 2, and the tank body 1 is provided with a water inlet pipe 3, a drain pipe 4, an exhaust pipe 5, a medicine feeding pipe 6 and The discharge pipe 7, the side of the tank body 1 is provided with a material taking hole (not shown), the said material taking hole is equipped with a detachable observation window 8, the side of the said tank body 1 is provided with a pump body 9, said tank body 1 A carrier plate 10 is arranged inside the body 1, and an annular air chamber 11 is arranged inside the carrier plate 10. The exhaust nozzle of the pump body 9 is connected with an exhaust pipe 12, and the exhaust pipe 12 runs through the tank body 1 and the The carrier plate 10 is provided, and the exhaust pipe 12 is provided with a one-way valve (not shown), and the end of the exhaust pipe 12 is located in the annular air chamber 11, and the exhaust pipe 12 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com