Construction technology of deck crane for hoisting entire segment of composite girder of cable-stayed bridge based on eccentric load lateral movement

A construction technique and technology of laminated beams, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor economic benefits, high cost, and heavy equipment assembly workload, and achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

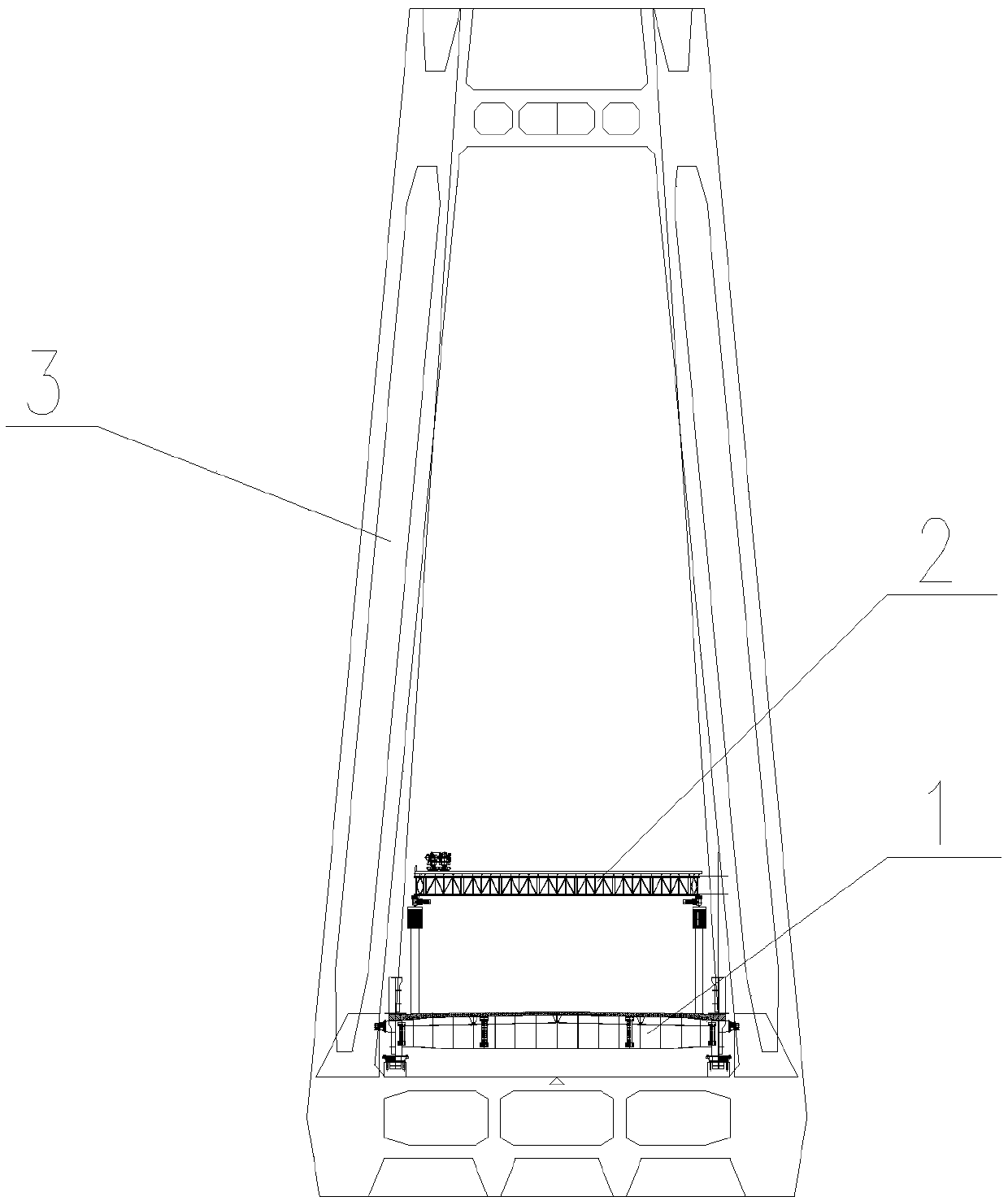

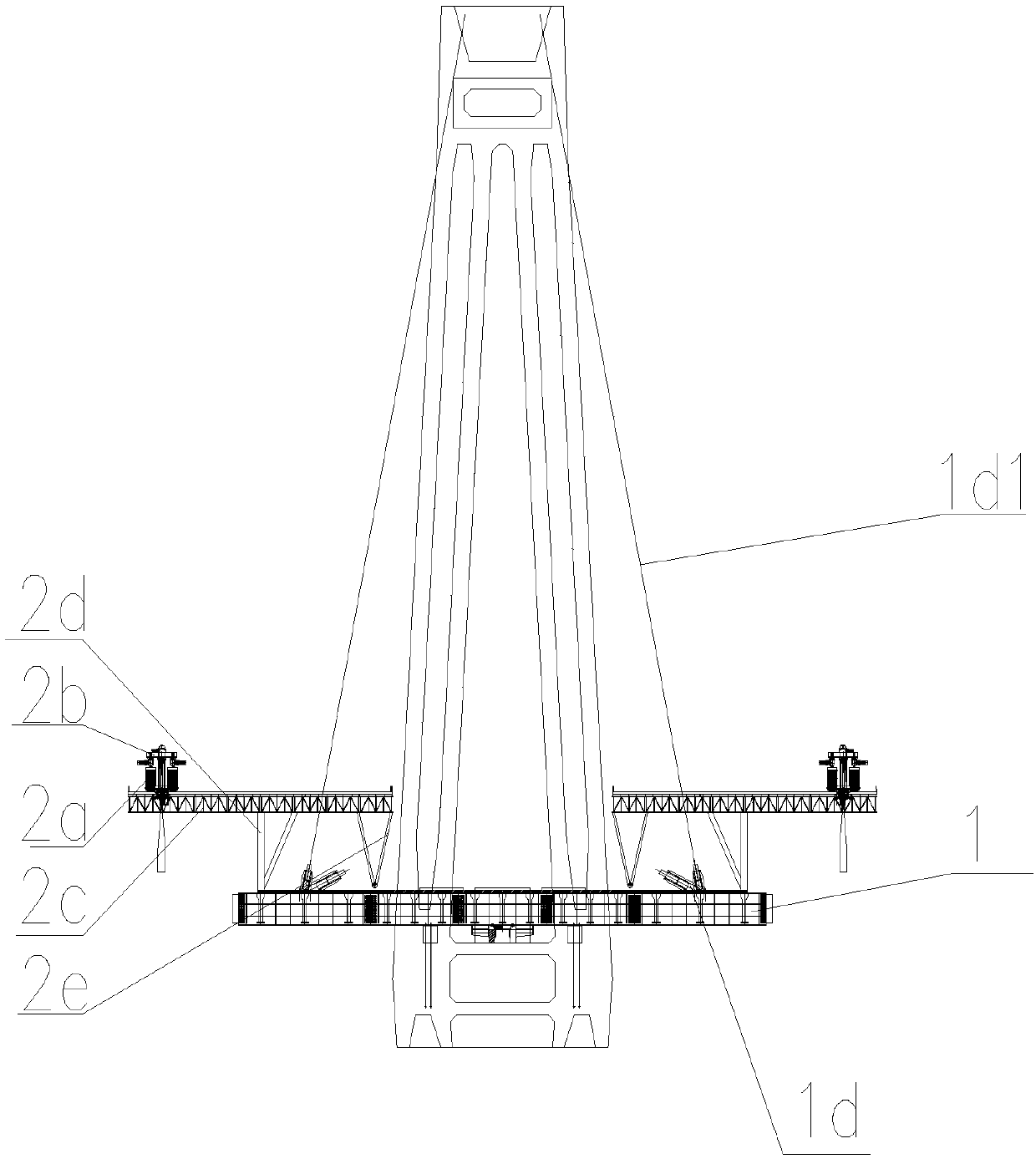

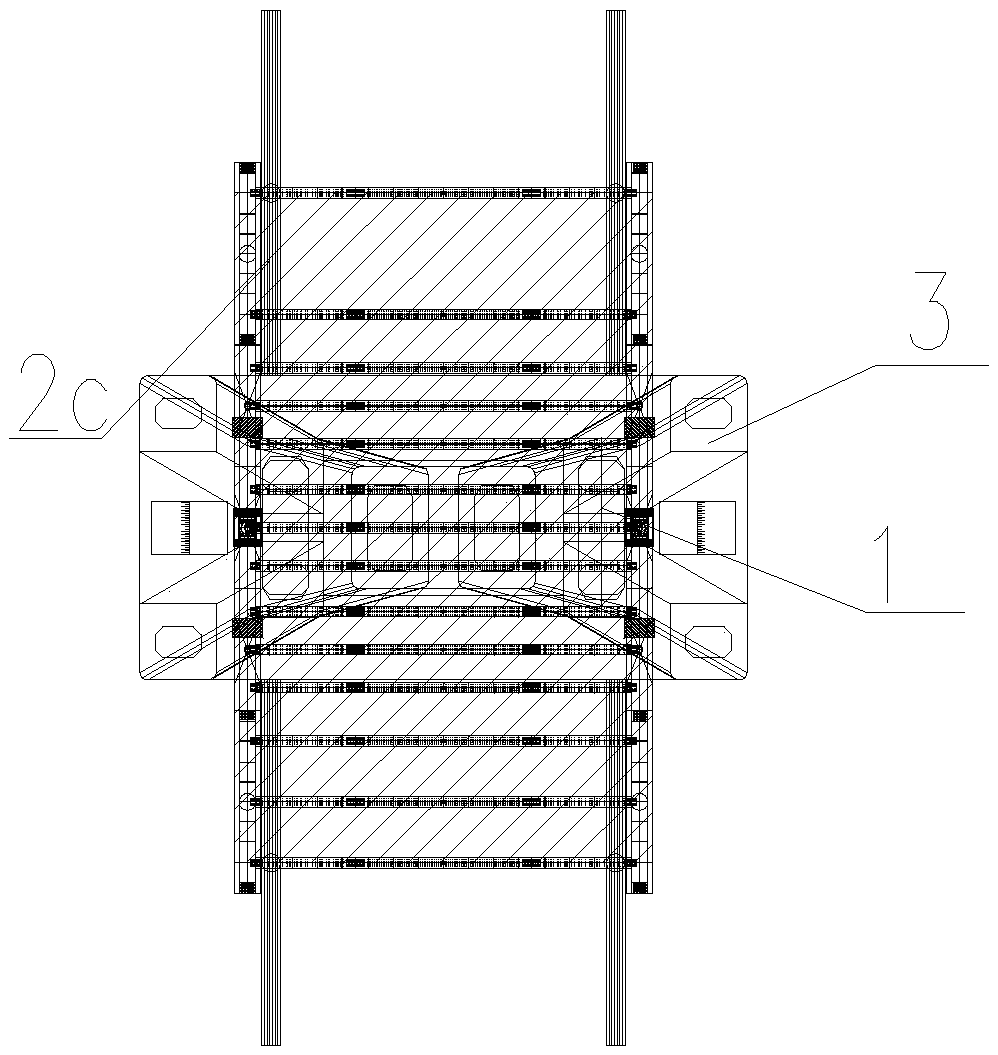

[0059]Referring to the accompanying drawings, it can be seen that the construction process of the bridge deck crane for hoisting the entire segment of the composite beam of the cable-stayed bridge based on the partial load lateral movement is characterized in that it includes the tower area 3, the bridge deck of the assembled beam section in the tower area 1, The whole section bridge deck crane 2 and the section beam 4, the bridge deck 1 of the assembled beam section in the tower area is located at the lower part of the tower area 3, and the bridge deck of the assembled beam section 1 in the tower area is provided with a beam transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com