Monitoring device for dynamically sensing single-sided chemical mechanical planarization processing

A technology of chemical machinery and monitoring devices, applied in the control of workpiece feed movement, grinding devices, metal processing equipment, etc., can solve the problems of large external interference, single testing methods, and low precision, and achieve simplified process flow, The effect of reducing clamping and improving processing and manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

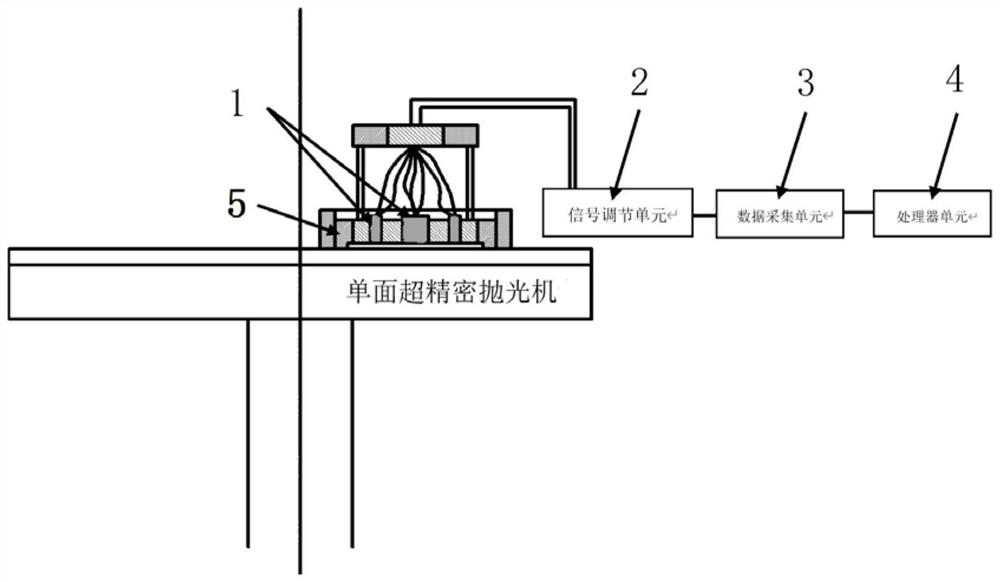

[0037]For example, in the process of grinding sapphire with free abrasives, the acoustic emission sensor and the three-dimensional force sensor arranged in a cross shape on the sensor fixture respectively collect the physical quantities of stress waves generated by abrasive rolling and scribing the workpiece surface and convert them into analog signals of sound and force. , through the signal conditioner to amplify the perceived analog signal and filter the clutter, the 10M sampling rate, 16-bit channel data collector collects the adjusted analog signal and converts it into a digital signal, and then through digital filtering, Noise reduction, preprocessing of stored data, transfer of preprocessed data to computer and data signal processing for standardization and sparseness, time-frequency conversion, feature extraction, modal identification, and display of acoustic emission time-frequency-intensity curve and time - Friction coefficient curve, the time-material removal rate cu...

Embodiment 2

[0039] For example, in the process of grinding silicon carbide with bonded abrasives, the acoustic emission sensor and temperature sensor arranged in a multi-ring layout on the sensor fixture respectively collect the stress waves and frictional thermal physical quantities generated on the surface of the workpiece due to the frictional mechanical action of the abrasive pads. The hot analog signal is amplified, amplified and filtered by the signal conditioner. The 15M sampling rate, 19-bit channel data collector collects the adjusted analog signal and converts it into a digital signal. After digital filtering, noise reduction, and preprocessing of stored data, the preprocessed data is transferred to the computer and subjected to data signal processing of standardization and sparseness, time-frequency conversion, feature extraction, and modal recognition, showing that the acoustic emission time-frequency- Intensity curve and time-temperature curve, the time-surface roughness curve...

Embodiment 3

[0041] For example, in the chemical mechanical polishing of silicon wafer from copper layer to tantalum layer, the three-dimensional force sensor and temperature sensor on the sensor fixture in a star-shaped layout respectively collect the stress wave and frictional heat generated on the surface of the workpiece and convert them into sound and heat. The analog signal is amplified, amplified and filtered by the signal conditioner. The 20M sampling rate, 15-bit channel data collector collects the adjusted analog signal and converts it into a digital signal. Filtering, noise reduction, stored data preprocessing, the preprocessed data is transferred to the computer and subjected to data signal processing for standardization and sparseness, time-frequency conversion, feature extraction, and modal identification, showing the time-friction coefficient curve and time -Temperature curve, qualitatively analyze the type of wafer based on the friction coefficient and temperature signal, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com