Biological particle furnace

A technology of biological particles and furnaces, which is applied in household stoves/stoves, stoves/stoves with hot water devices, household heating, etc., can solve the problems of polluting the environment, wasting resources, and waste, and achieves high combustion efficiency and high combustion efficiency. Thorough, full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

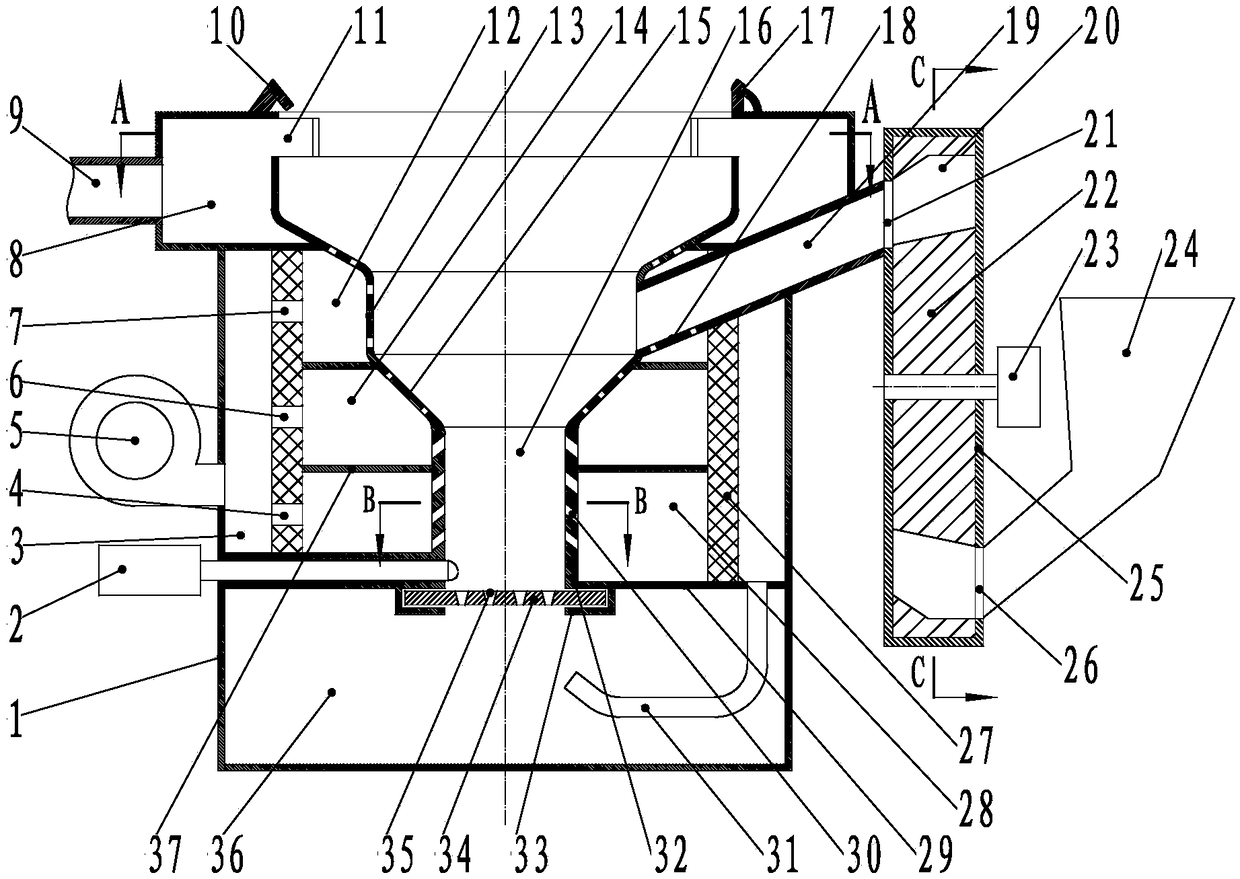

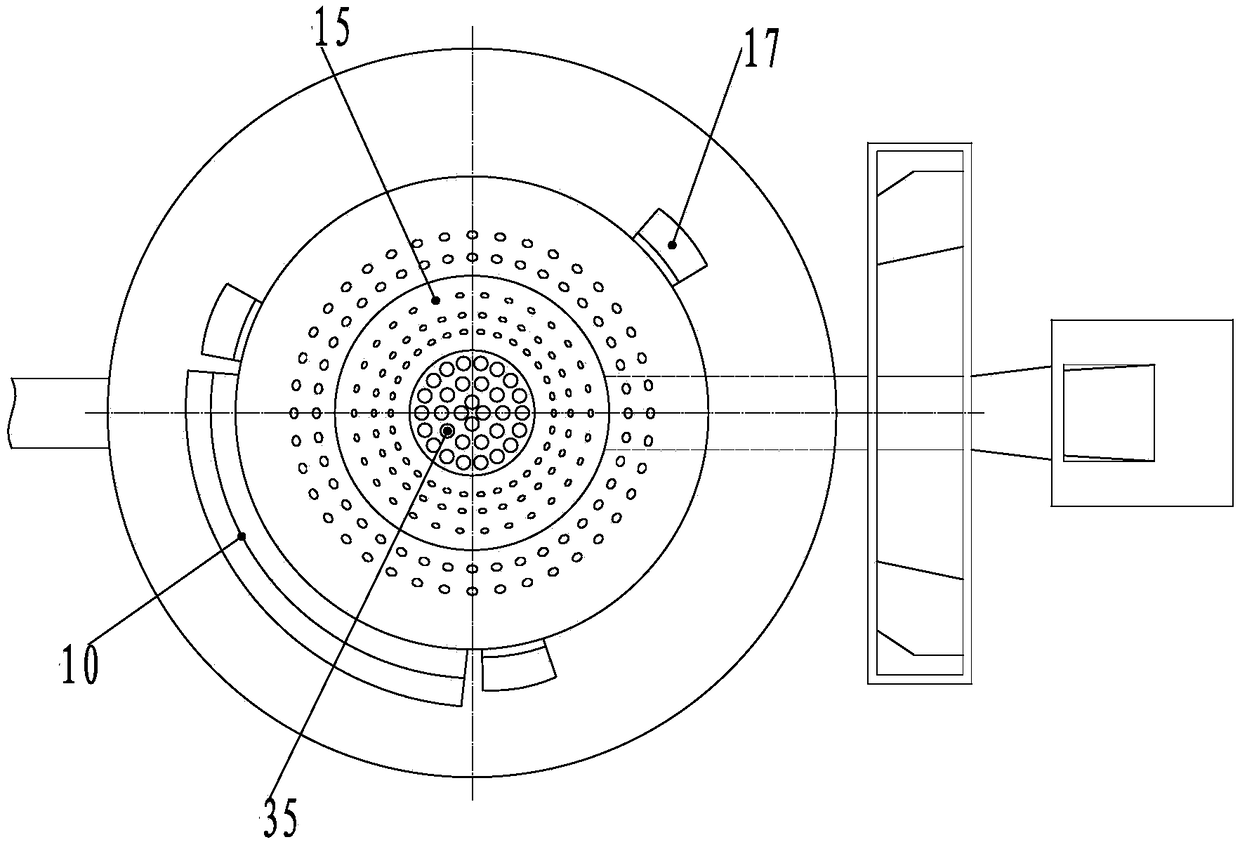

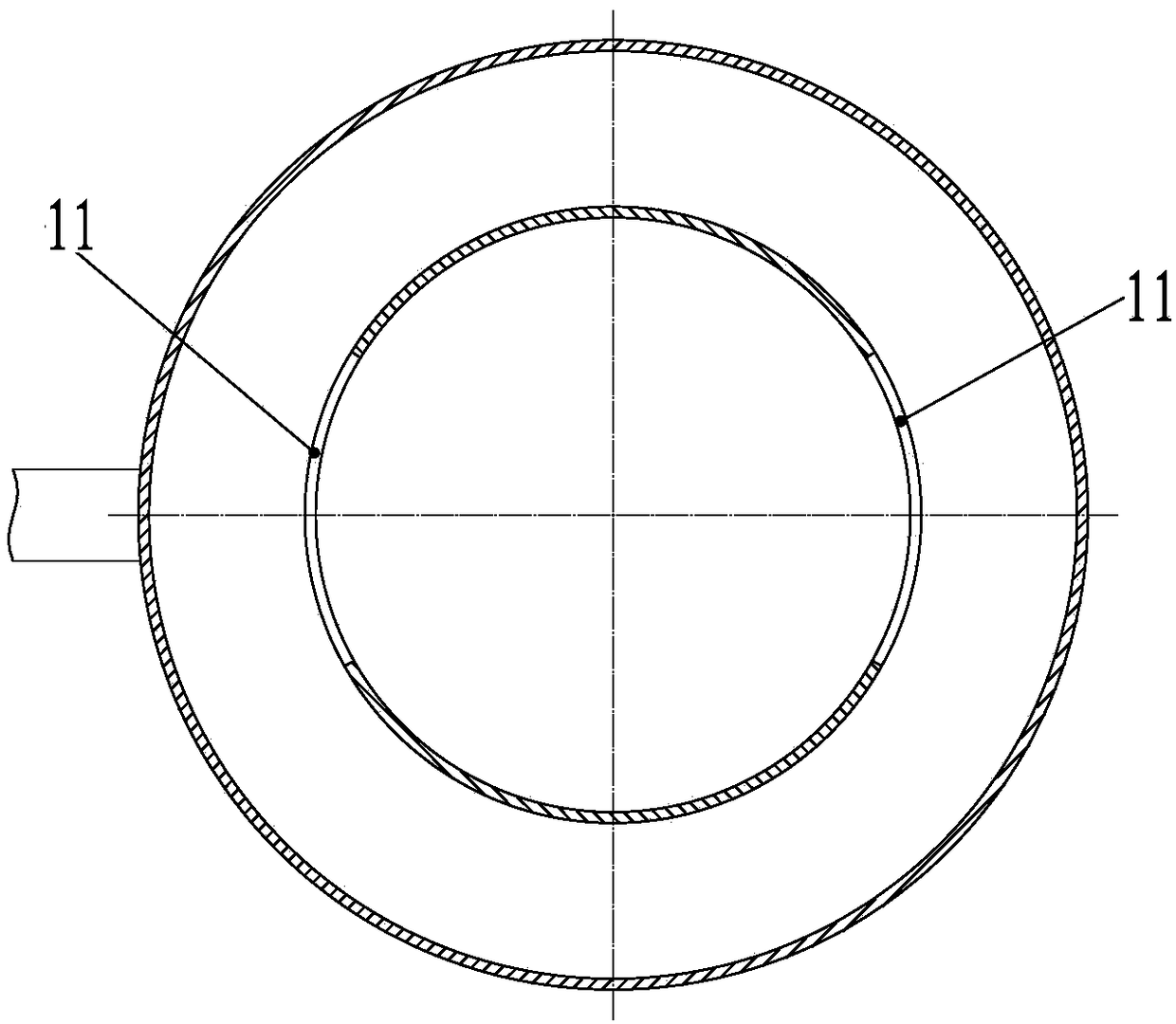

[0025] The biological particle furnace of the present invention will be further described below in conjunction with the accompanying drawings and specific examples:

[0026] figure 1 It is a structural schematic diagram of the biological particle furnace of the present invention, figure 2 yes figure 1 top view of image 3 yes figure 1 A-A sectional view in, Figure 4 yes figure 1 The B-B sectional view in, Figure 5 yes figure 1 C-C sectional view in . In the figure, the furnace body 1 of the biological pellet furnace is provided with a furnace 16, and an ash bin 36 is arranged below the furnace 16. The furnace 16 is large up and down small and has a stepped shape, and a bellows is arranged between the furnace wall 32 and the furnace body 1. A heat insulating ring 27 is arranged in the bellows, and the heat insulating ring 27 divides the bellows into an inner bellows and an outer bellows, the outer bellows 3 communicate with the blower 5, and the inner bellows are div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com