A rotary umbrella drying equipment

A drying equipment, rotary technology, applied in the field of rotary umbrella drying equipment, can solve the problems of high power consumption, high cost of electronic devices, short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

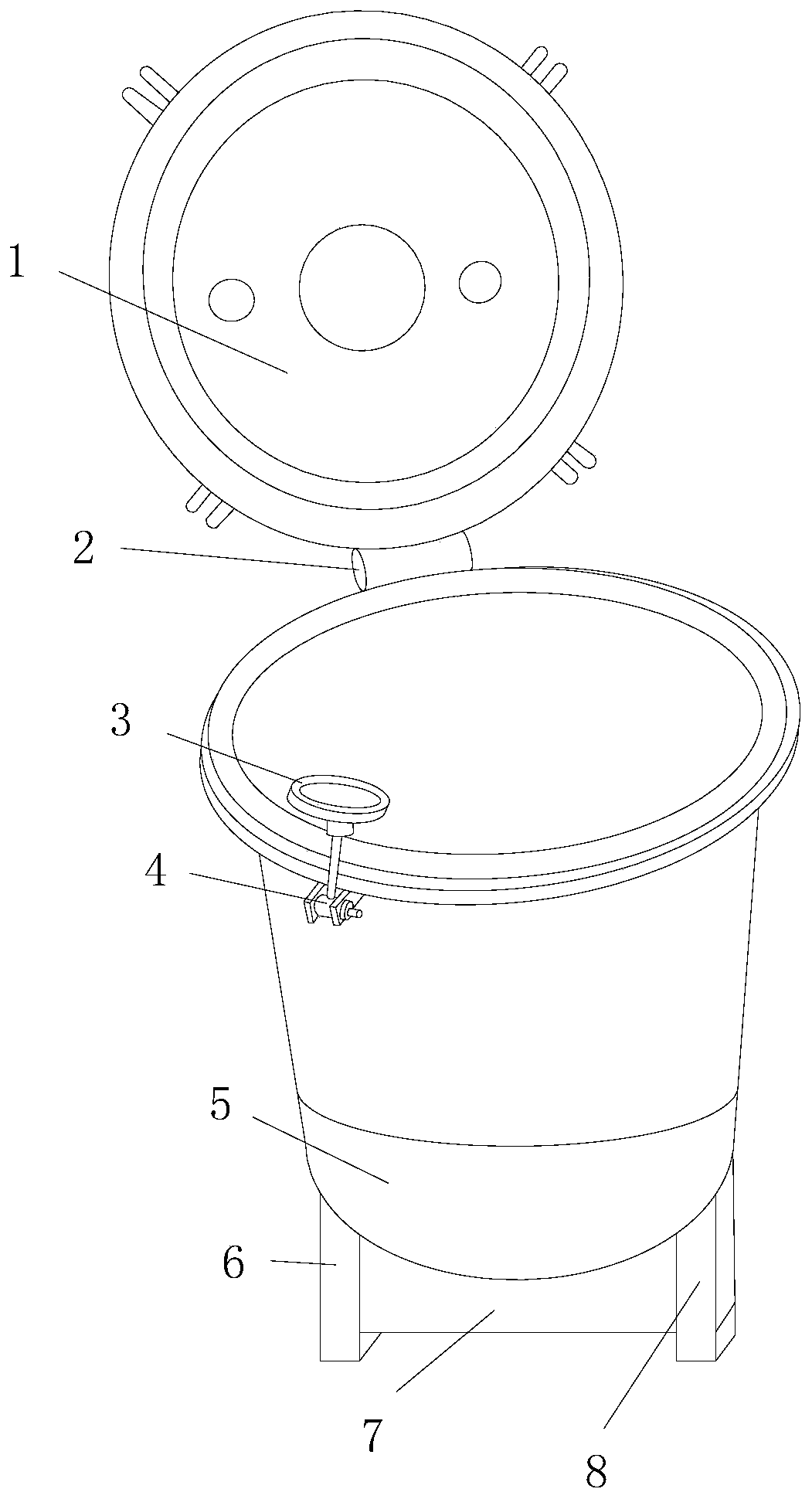

[0025] see Figure 1-Figure 5 , the present invention provides a rotary umbrella drying equipment, the structure of which includes a cylinder cover 1, a hinge 2, a handle 3, a clip 4, a drying system 5, a first leg 6, a water storage tank 7, a second leg 8, The drying system 5 is movably connected to the cylinder cover 1 through the hinge 2, the clip 4 is in movable contact with the cylinder cover 1, the clip 4 and the handle 3 are fixed together, and the drying system A first leg 6 and a second leg 8 are installed on the bottom of the 5, and a water storage tank 7 is installed between the first leg 6 and the second leg 8, and the water storage tank 7 communicates with the drying system 5.

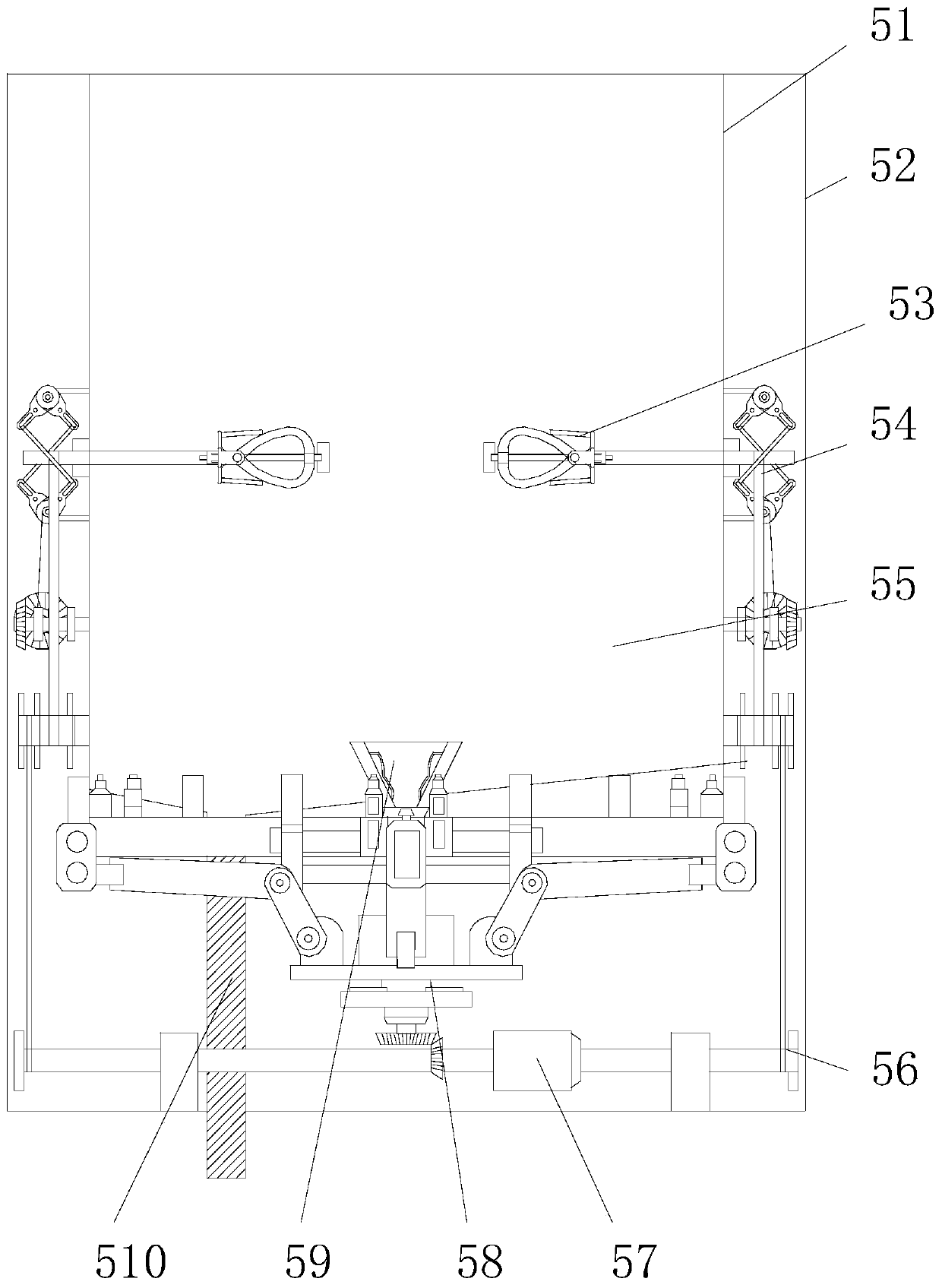

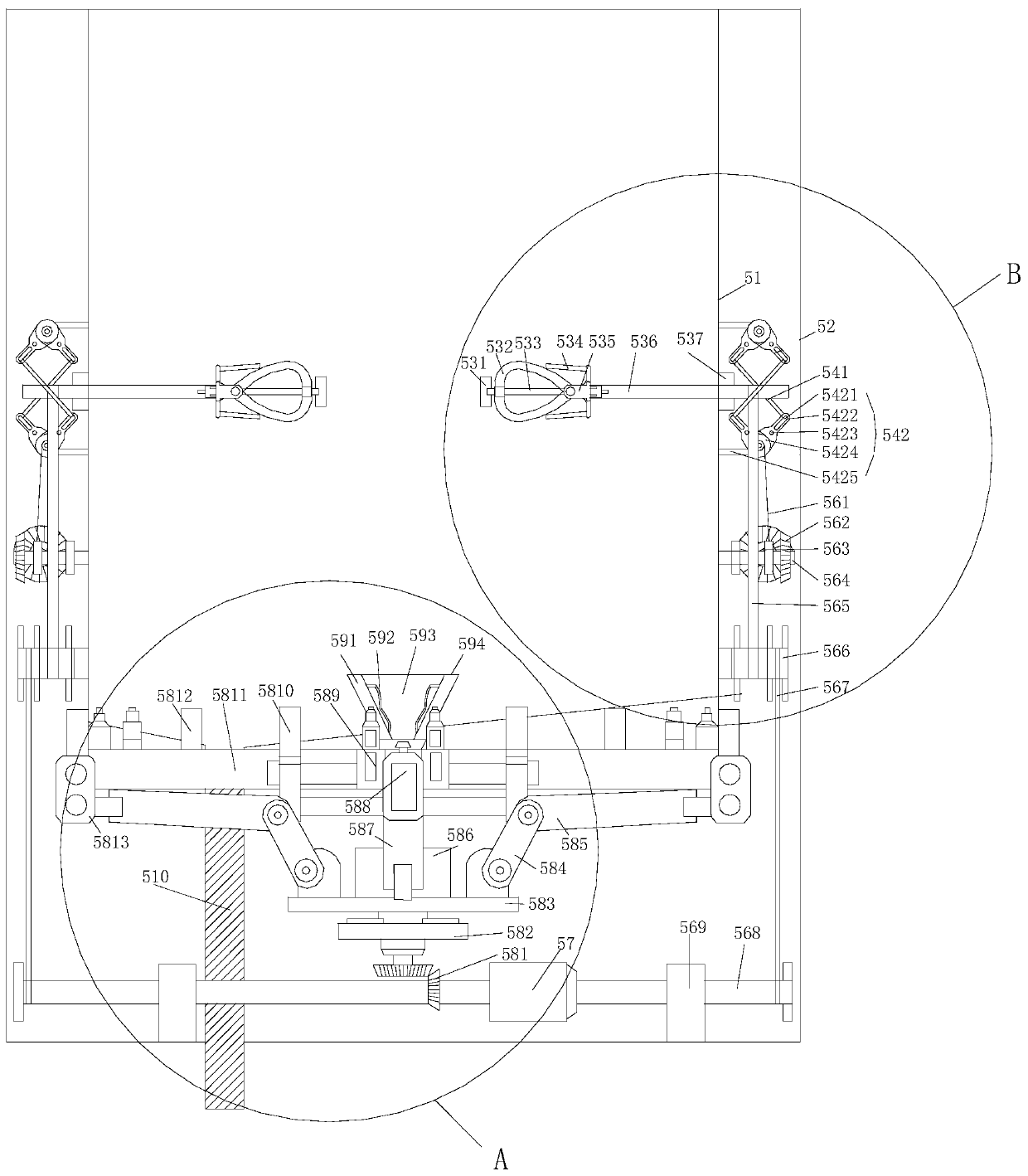

[0026] The drying system 5 is provided with an inner rotating cylinder 51, an outer shell 52, an umbrella handle clamping structure 53, a twisting pause mechanism 54, an umbrella placement cavity 55, a three-dimensional rotating structure 56, a motor 57, a chassis rotating structure 58, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com