Manufacturing method of test piece for tensile test of chopped bundle fibers for fixing cement concrete

A technology of cement concrete and tensile test, which is applied in the preparation of test samples and the use of stable tension/pressure to test the strength of materials, etc. It can solve the problems of damage detection data, inaccuracy, etc., so as to solve the damage of fibers and improve The effect of test efficiency and simplicity of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Mold structure description:

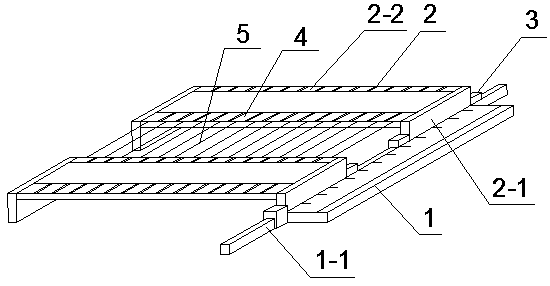

[0027] like figure 1 As shown, the mold assembly is mainly composed of a base 1 , two sets of frame-shaped molds 2 and a number of buckles 3 .

[0028] The base 1 is provided with a straight slide rail 1-1 with a scale, and one side of each group of frame-shaped molds 2 is provided with a slide block 2-1 matched with the straight slide rail 1-1. With the cooperation of the straight slide rail 1-1, the slider 2-1 can be positioned on the straight slide rail 1-1 through the buckle 3.

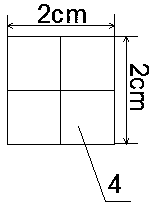

[0029] A plurality of slots 2-2 are arranged on the upper surface of each group of frame-shaped molds 2, and the length and width of each slot 2-2 are respectively 20 mm and 20 mm.

[0030] 2. Take the chopped strand glass fiber as an example to prepare the sample:

[0031] Through the movement of the slider 2-1 on the straight slide rail 1-1, according to the length of the fiber sample required for the test, the distance between the two groups of frame-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com