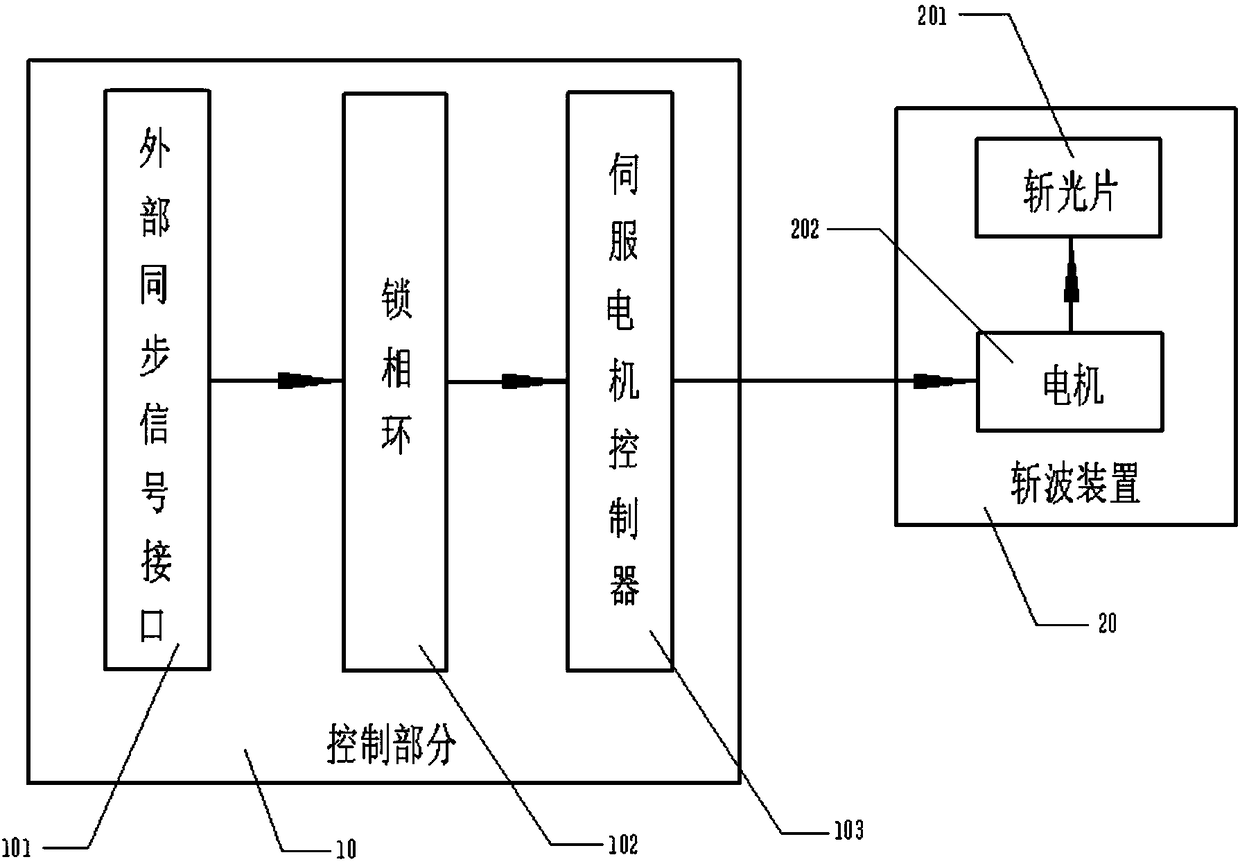

Mechanical light modulation device

A light modulation device and mechanical technology, applied in optics, optical components, instruments, etc., can solve problems such as low drive efficiency, image quality degradation, femtosecond laser pulse broadening, etc., to reduce processing difficulty, improve realization, and avoid samples Effects of overexposure or dye bleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

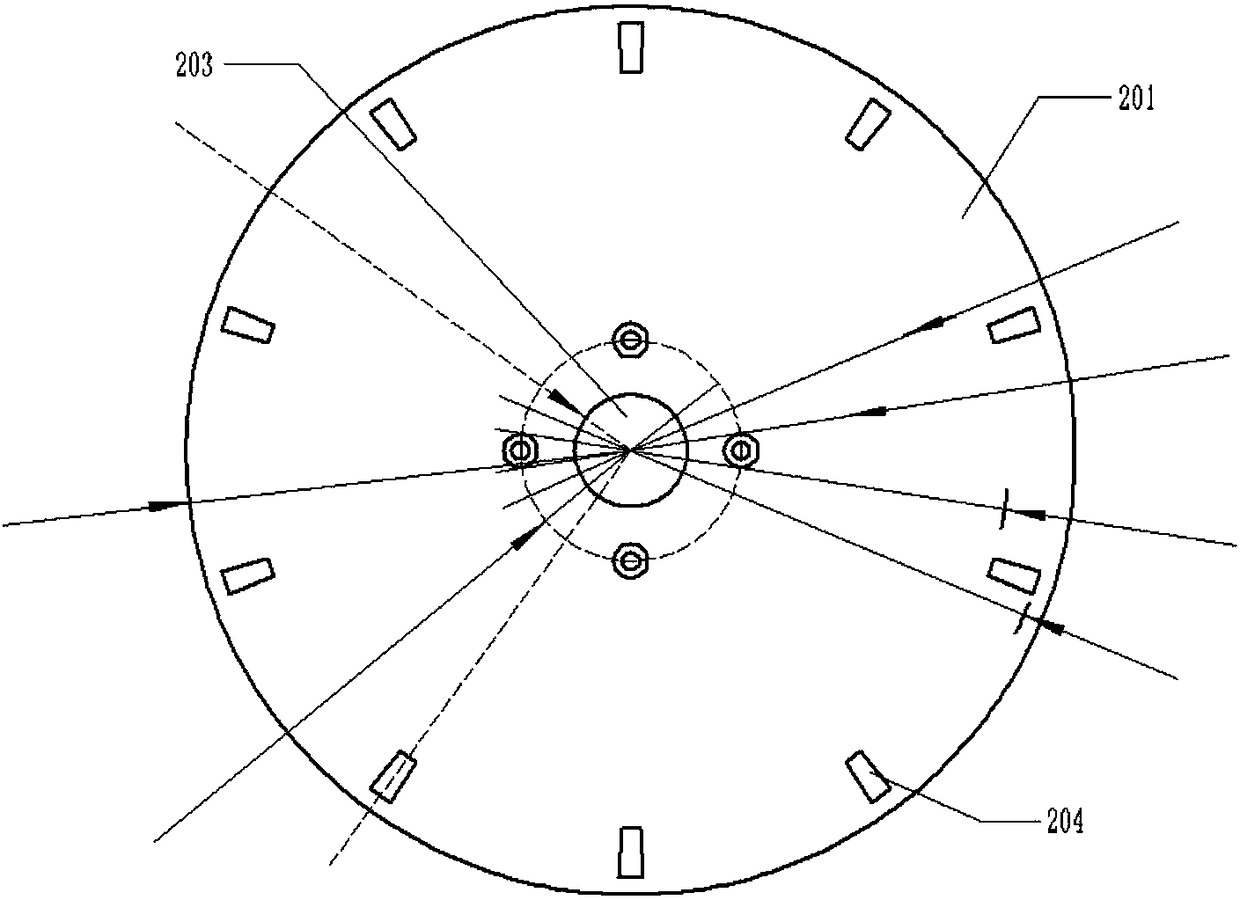

Embodiment 1

[0034]Implementation Example 1: The diameter of each chopping chip 201 is 100 mm, and the chip includes a complete blanking structure for realizing one frame scanning. Therefore, the rotational speed of the motor 202 is 1800 rpm, which is equivalent to 30 fps. The part near the circumference of the chopping sheet 201 is divided into 520 equal parts (15600 divided by 30), wherein 512 equal parts are partially punched, and the area of perforated in each equal part accounts for 88% of each part, and the area without holes Accounting for 12%, corresponding to 88% of each row of approximately uniform scanning and 6% of the leftmost and 6% of the blanking part of the rightmost, the perforated part allows the laser to pass through; the non-perforated part completely blocks the laser. The remaining 8 equal parts are not perforated, which corresponds to the process that the scanning head returns to the starting position of the first line of the next frame after the end of each frame....

Embodiment 2

[0035] Implementation example two: the motor 202 rotating speed increases N times, then the number of scanning lines that each chopping plate 201 comprises reduces N times, the laser beam diameter by chopping light 201 increases N times, can reduce the processing of chopping plate 201 like this Difficulty and implementation difficulty of focusing light path. Take the C-995 mechanical chopper of British Scitec Company as an example, the maximum speed of its electric motor is 10020rpm. In this application, the rotational speed of the motor 302 can be set to 9000rpm, which is increased by 5 times, and the number of scanning lines included in each chopping piece 201 is reduced by 5 times to 104 lines, and the diameter of the laser beam passing through the chopping piece 201 increases. 5 times larger at 4.75um. On this basis, if the chopping plate 201 is replaced with a light metal material, such as aluminum, and the weight of the chopping plate 201 is kept small, the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com