Collimating structure, manufacturing method thereof and display device

A technology for display panels and light-shielding layers, which is applied in optics, instruments, character and pattern recognition, etc. It can solve problems such as excessive distance between objects and optical sensing structures, light crosstalk, etc., so as to reduce the difficulty of processing technology and improve accuracy , good collimation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

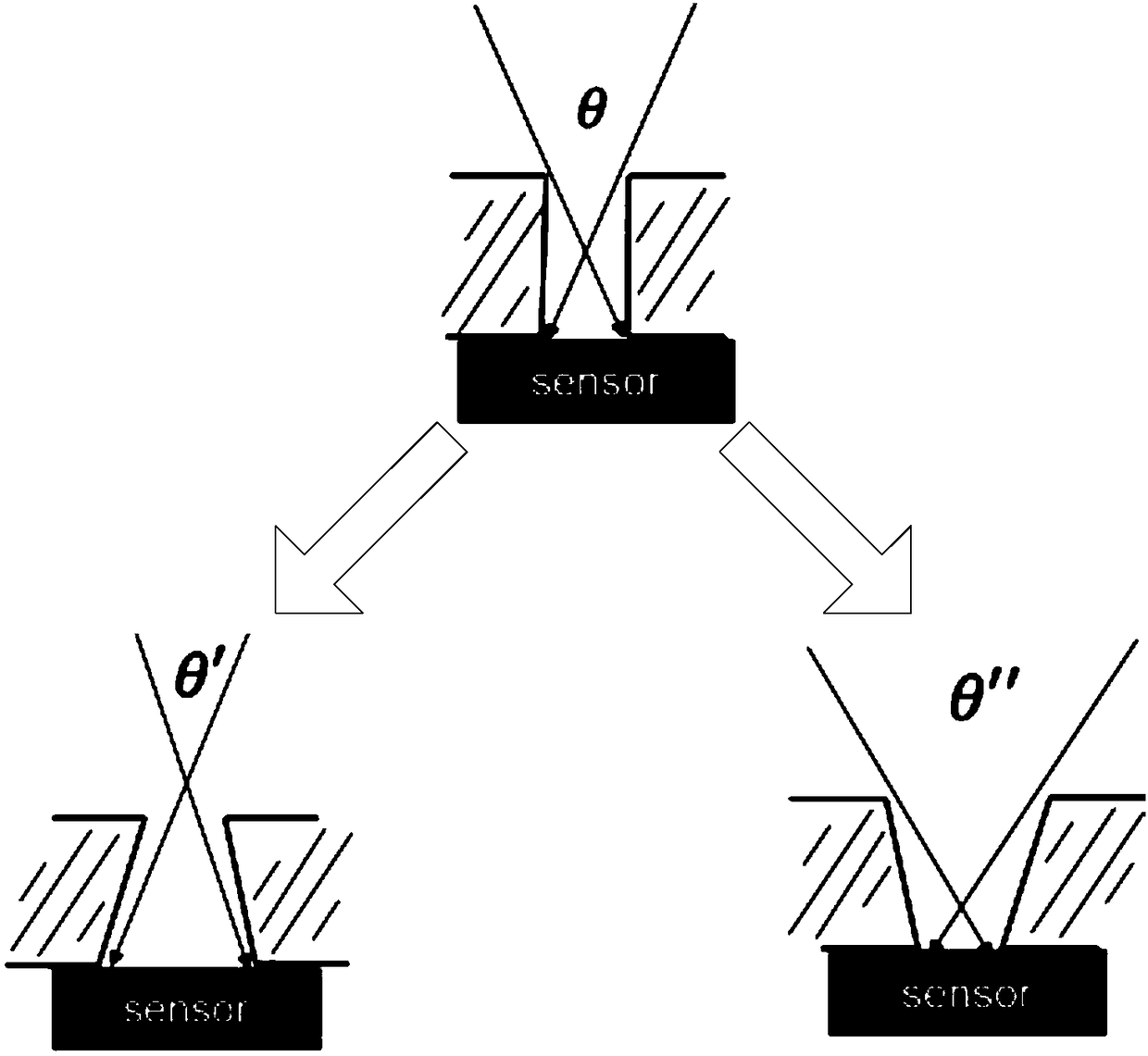

[0042] At present, in the process of optical pattern recognition, when the distance between the finger and the sensor is large, the obtained image will be blurred due to the scattering of the light reflected by the finger, which in turn leads to the pattern that is recognized based on the light received by the sensor The problem of inaccurate information. In order to accurately obtain the information of the valleys and ridges of the texture, at present, the through-hole filter method and the lens and diaphragm method are generally used, and a collimating structure is added to the sensor. The through-hole structure requires specific materials to achieve a high aspect ratio, such as figure 1 As shown, the existing process will have a similar “chamfer” structure in the lithography process, and it cannot guarantee that the sidewall of the through-hole structure is strictly perpendicular to the light incident surface, so that the light receiving angle becomes larger, and the light in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com