High-precision valve control method

A valve control and control method technology, which is applied in the control system, motor control, position/direction control, etc., can solve the problems of unable to realize motor speed regulation, target valve overshoot, large motor inertia, etc., to achieve flexible adjustment of operating speed, Effect of reducing mechanical shock and low performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

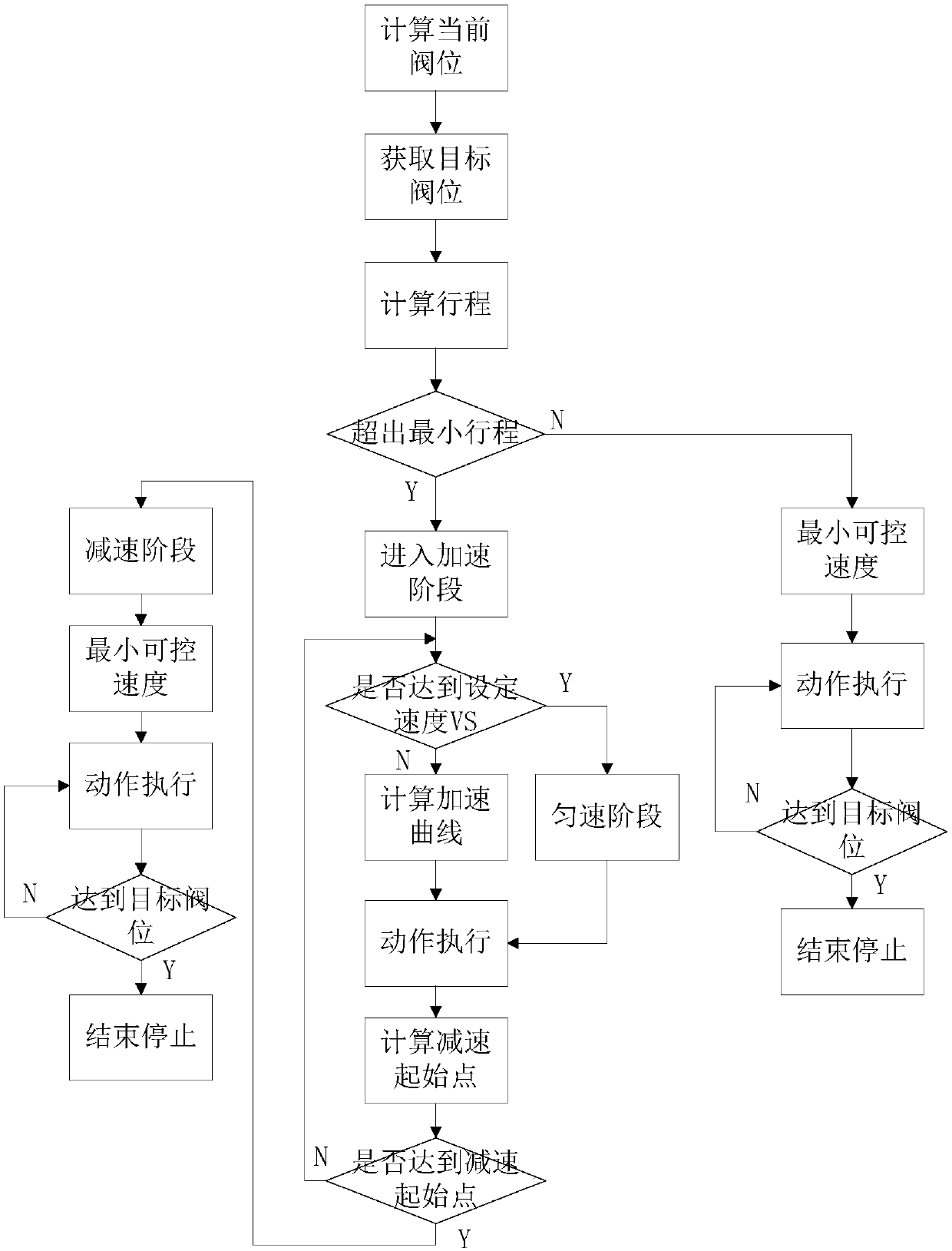

[0038] Such as figure 1 As shown, the high-precision valve control method of the present invention is mainly divided into the following steps:

[0039] Step 1. Use the MCU on the circuit board to read the value of the valve position sensor, then read the saved switch limit value, use the two-point method to calculate the current valve position opening, and convert it into a percentage. It is most direct to use this data format to participate in the calculation .

[0040] Step 2, implement the scanning external command, and calculate the target valve position according to the signal type. Commonly used commands include digital switch commands, analog signals, and bus control signals. After receiving the open signal from the switch signal, the target valve position is converted to 100%. After receiving the switching signal, the target valve position is converted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com