Typical power plant lightning arrester configuration and insulation coordination modeling method

A technology of insulation coordination, modeling method, applied in the field of electric power, can solve problems such as lack of solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

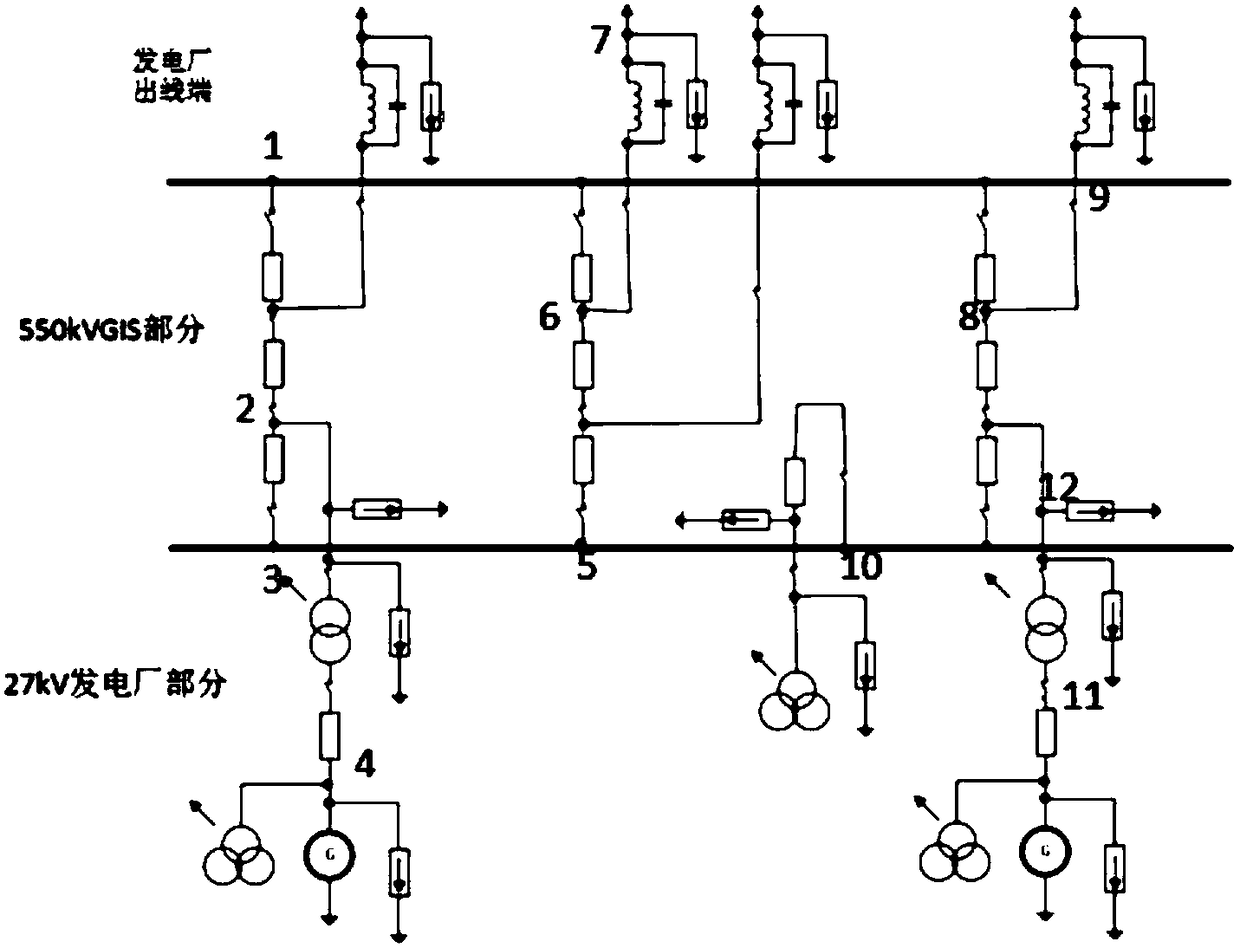

[0135] In a typical power plant design, it is necessary to configure surge arresters at the generator outlet, transformer outlet, busbar, GIS inlet, and 500kV outlet of the power plant. The determination of the final parameters of the arrester refers to the provisions of "Technical Regulations for Overvoltage Protection of Power Equipment", "Regulations for Lightning Arresters" and "Code for Design of Overvoltage Protection and Insulation Coordination of AC Electrical Installations", and the specific calculation process is obtained. The first specific implementation example: 27kV insulation coordination design process:

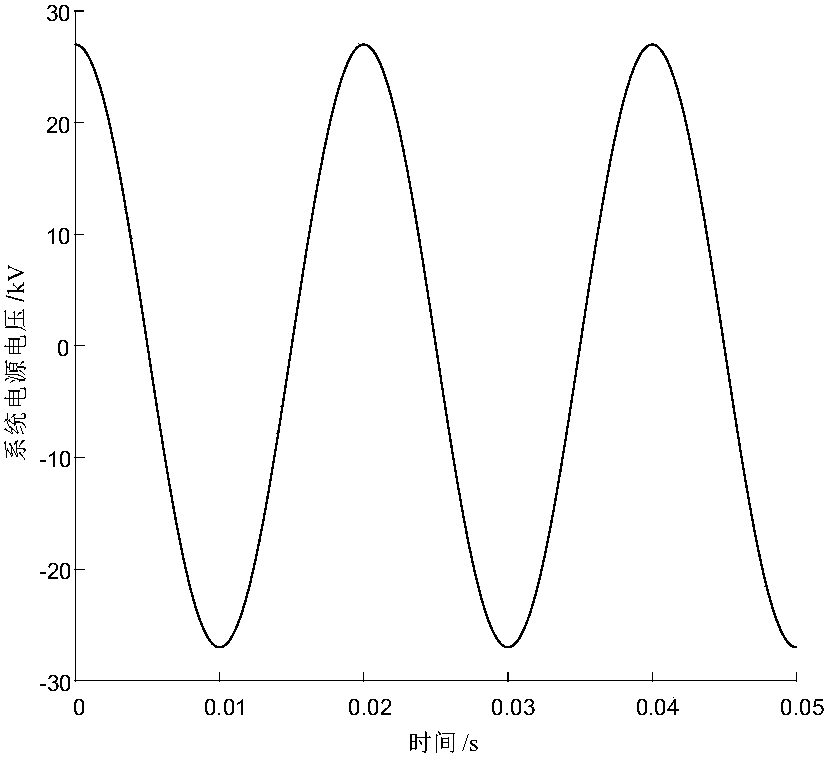

[0136] 1.1 Input volume

[0137] a) The highest system voltage Us=24kV(r.m.s, phase to phase)

[0138] b) Pollution level: mild

[0139] c) Altitude: 1000m

[0140] d) Lightning shock protection level of arrester Ups=410kV, Upl=80kV

[0141] e) Insulation distance: 3m inside, 5m outside

[0142] f) Number of iron tower lines (number of lines entering the su...

no. 2 Embodiment

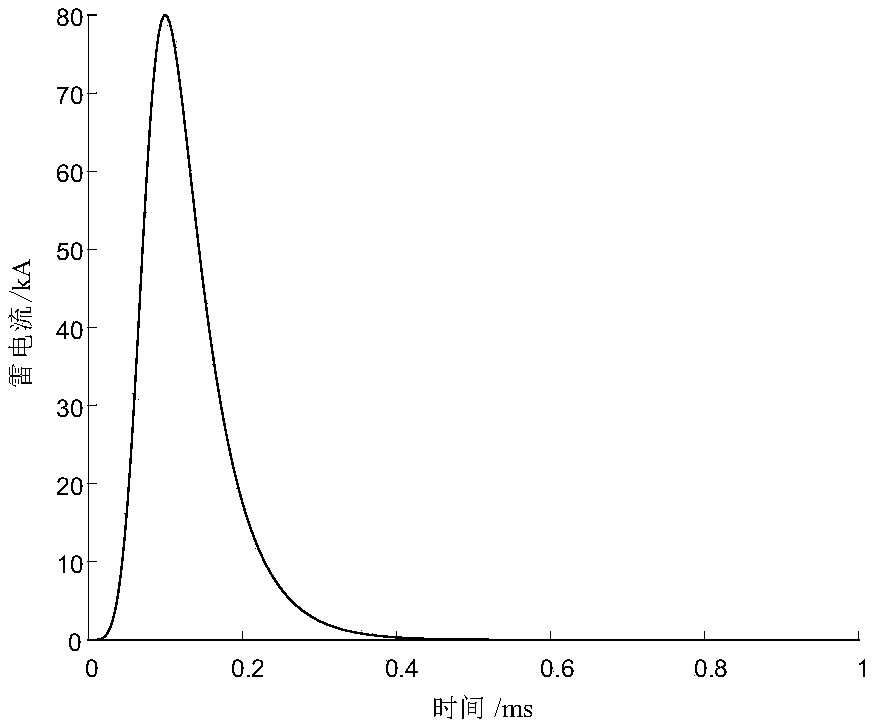

[0152] The second specific implementation example of the present invention: 500kV insulation coordination calculation process:

[0153] 2.1 Input quantity:

[0154] a) System nominal voltage U n =500kV;

[0155] b) The highest voltage U of the equipment m =550kV;

[0156] c) Reference voltage 1.0p.u.=317kV;

[0157] d) Altitude H;

[0158] e) Factor A for overhead lines;

[0159] f) The minimum number of overhead lines n connected to the substation;

[0160] g) The distance L between the arrester and the protected equipment;

[0161] h) Line span L sp ;

[0162] i) The length L of the overhead line when the lightning flashover rate is an acceptable failure rate a ;

[0163] j) The test conversion factor a for converting the required short-duration power frequency voltage into the operating impulse withstand voltage in Table 3 1 (inner insulation), a 2 (outer insulation);

[0164] k) air gap distance D;

[0165] l) ground height H t

[0166] 2.2 Parameter def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com