Separator plate, membrane electrode assembly and fuel cell

一种燃料电池、分离器的技术,应用在燃料电池、燃料电池的零部件、收集器/分离器等方向,达到低电流强度、减小功率密度、电流减小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

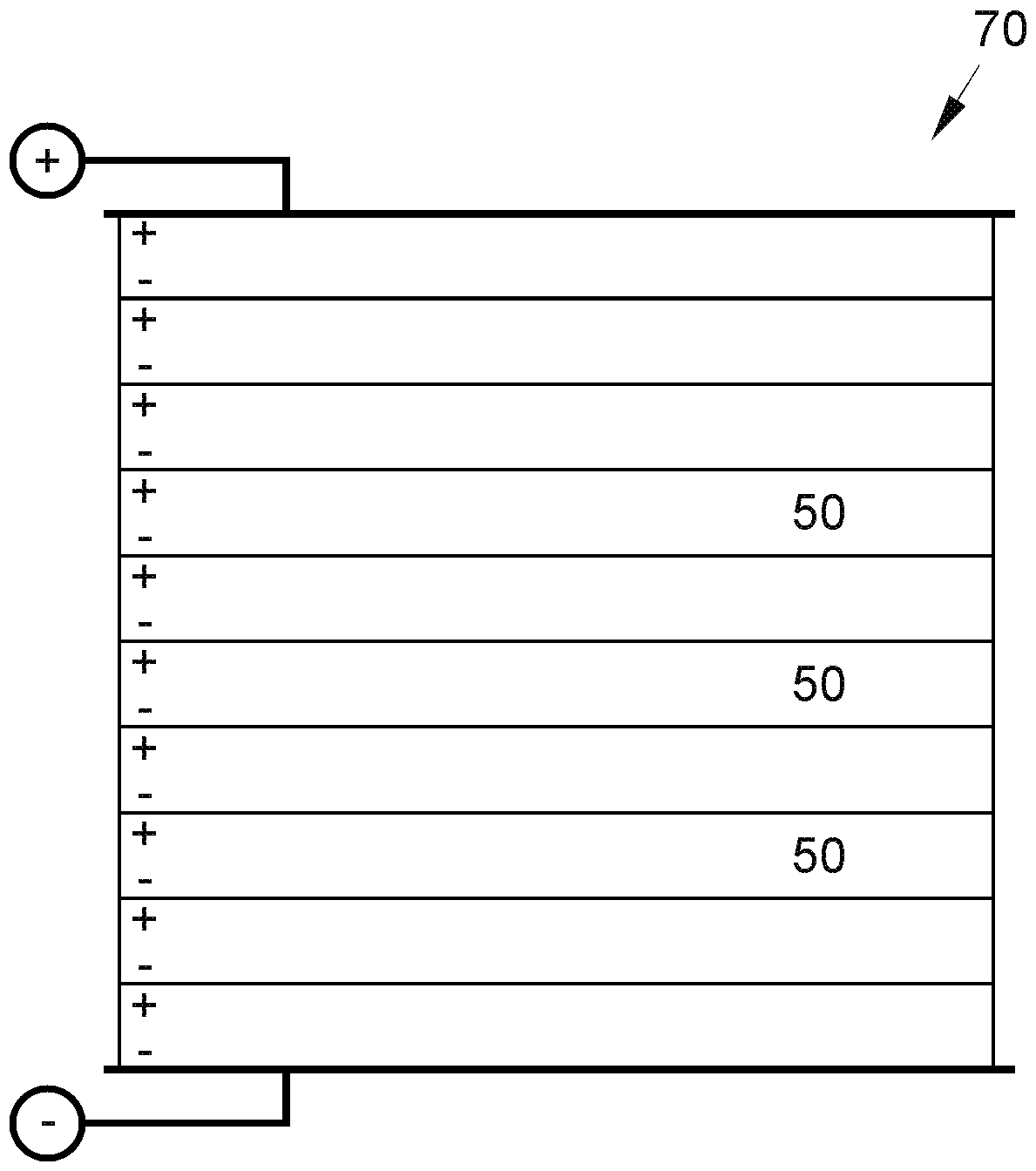

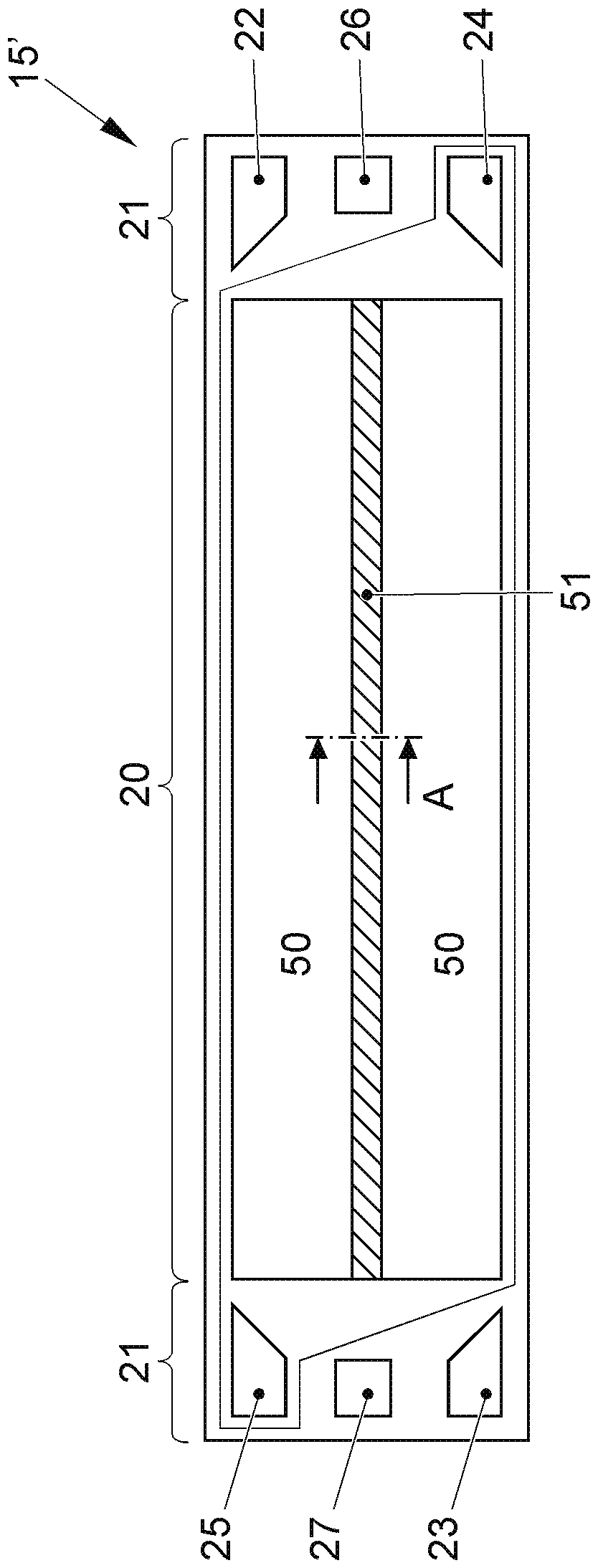

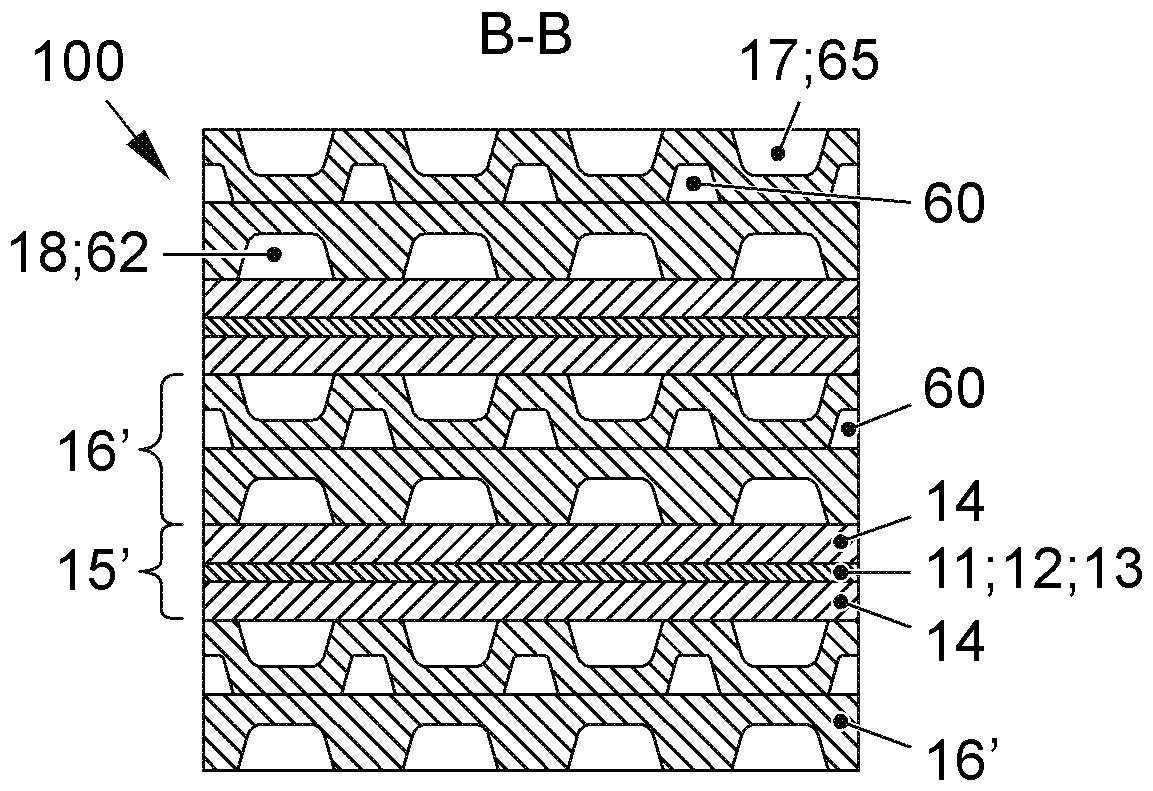

[0051] Figure 1A A section of a fuel cell stack, indicated overall at 100 , of which only two individual fuel cells 10 are shown here, is shown. Each fuel cell 10 has a polymer electrolyte membrane 11 made of an electrolyte-conducting, in particular proton-conducting, polymer material. Typically, polymeric materials require a certain humidity in order to maintain their electrolyte conductivity. A respective catalyst layer, namely the anode catalyst layer 12 and the cathode catalyst layer 13 adjoins both sides of the membrane 11 . Catalyst layers 12 and 13 comprise a catalytic material, typically a noble metal, especially platinum. Typically, the catalyst layers 12 , 13 also comprise a porous, electrically conductive carrier material on which a catalytic material, for example a carbon-based material, is finely dispersed. The catalyst layers 12, 13 may comprise further components such as polymeric binder materials and the like.

[0052] A respective gas diffusion layer (GDL)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com