Six-phase linear induction motor energy chain switching control system and six-phase linear induction motor energy chain switching control method

A linear induction motor and control system technology, applied in control systems, AC motor control, electrical components, etc., to achieve the effects of lower temperature rise, strong adaptability, and simple and flexible control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

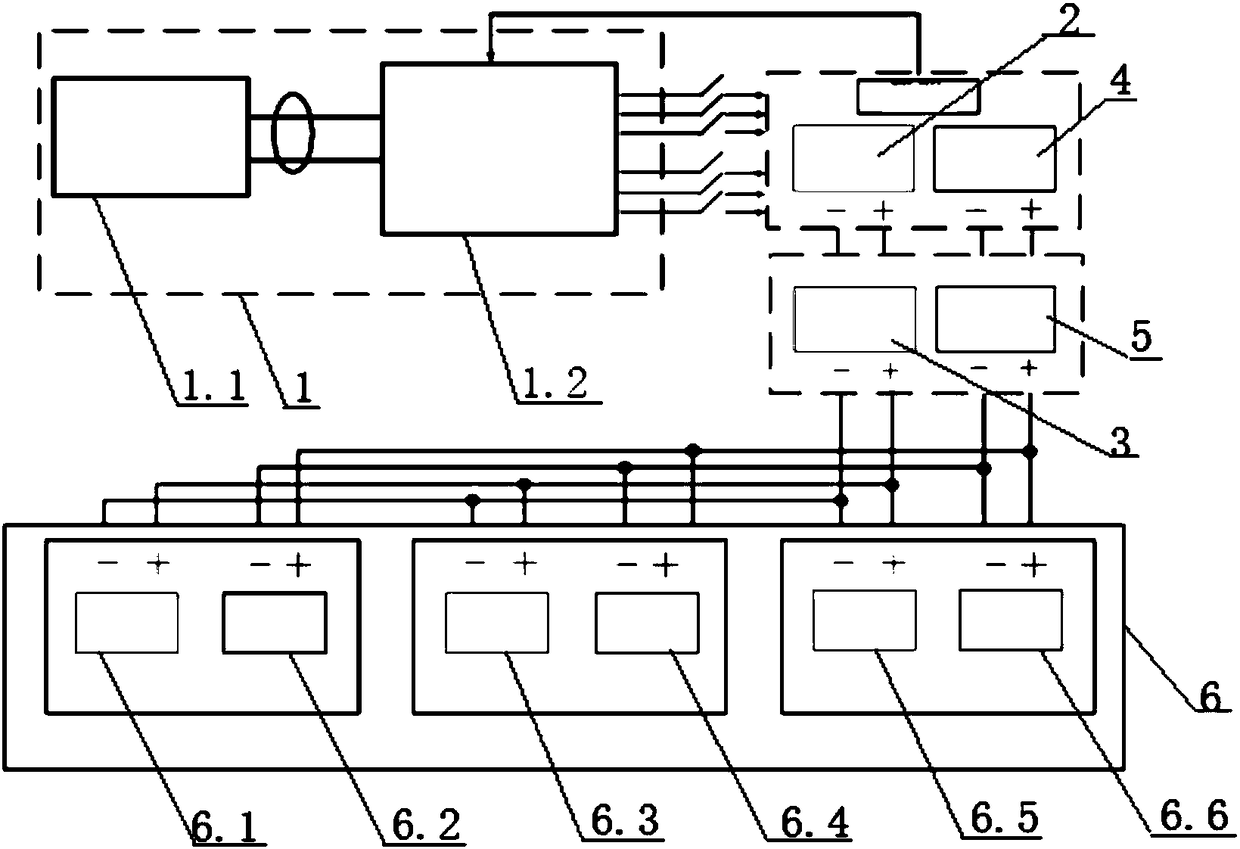

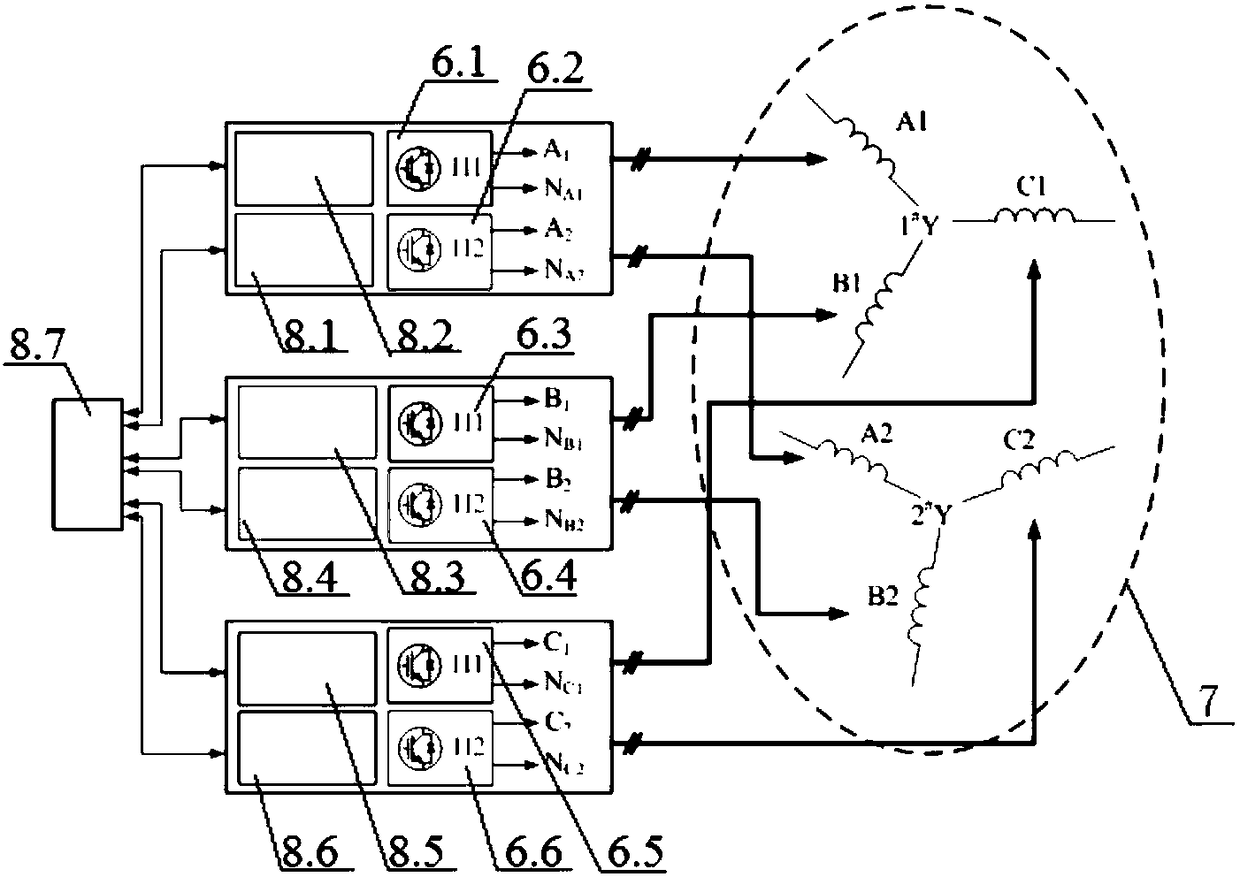

[0049] A six-phase linear induction motor 7 energy chain switching control system, the first output end of the power generation unit 1 transmits electric energy to the first energy storage unit 3 through the first rectification circuit 2, and the second output end of the power generation unit 1 is rectified by the second The circuit 4 transmits electric energy to the second energy storage unit 5, the first energy storage unit 3 and the second energy storage unit 5 are respectively connected to the input terminal winding coil of the six-phase linear induction motor 7 through the inverter unit 6, and the control terminal of the inverter Connect the signal output of the control unit 8. The power generation unit 1 comprises a prime mover 1.1 and a generator 1.2 connected to said prime mover 1.1 via a generator shaft.

[0050] Preferably, the inverter unit 6 includes six inverters, and the six inverters are respectively marked as the first inverter 6.1, the second inverter 6.2, the...

Embodiment 2

[0059] A six-phase linear induction motor 7 energy chain switching control method: including dual energy chains, the dual energy chains include a first energy chain and a second energy chain, and the first energy chain is rectified from the first output end of the power generation unit 1 The circuit 2 transmits electric energy to the first energy storage unit 3, the second energy chain transmits electric energy from the second output terminal of the power generation unit 1 to the second energy storage unit 5 through the second rectifier circuit 4, and the inverter unit 6 receives the power from the control unit 8 The control signal controls the first energy storage unit 3 and / or the second energy storage unit 5 to transmit electric energy to the six-phase linear induction motor 7 .

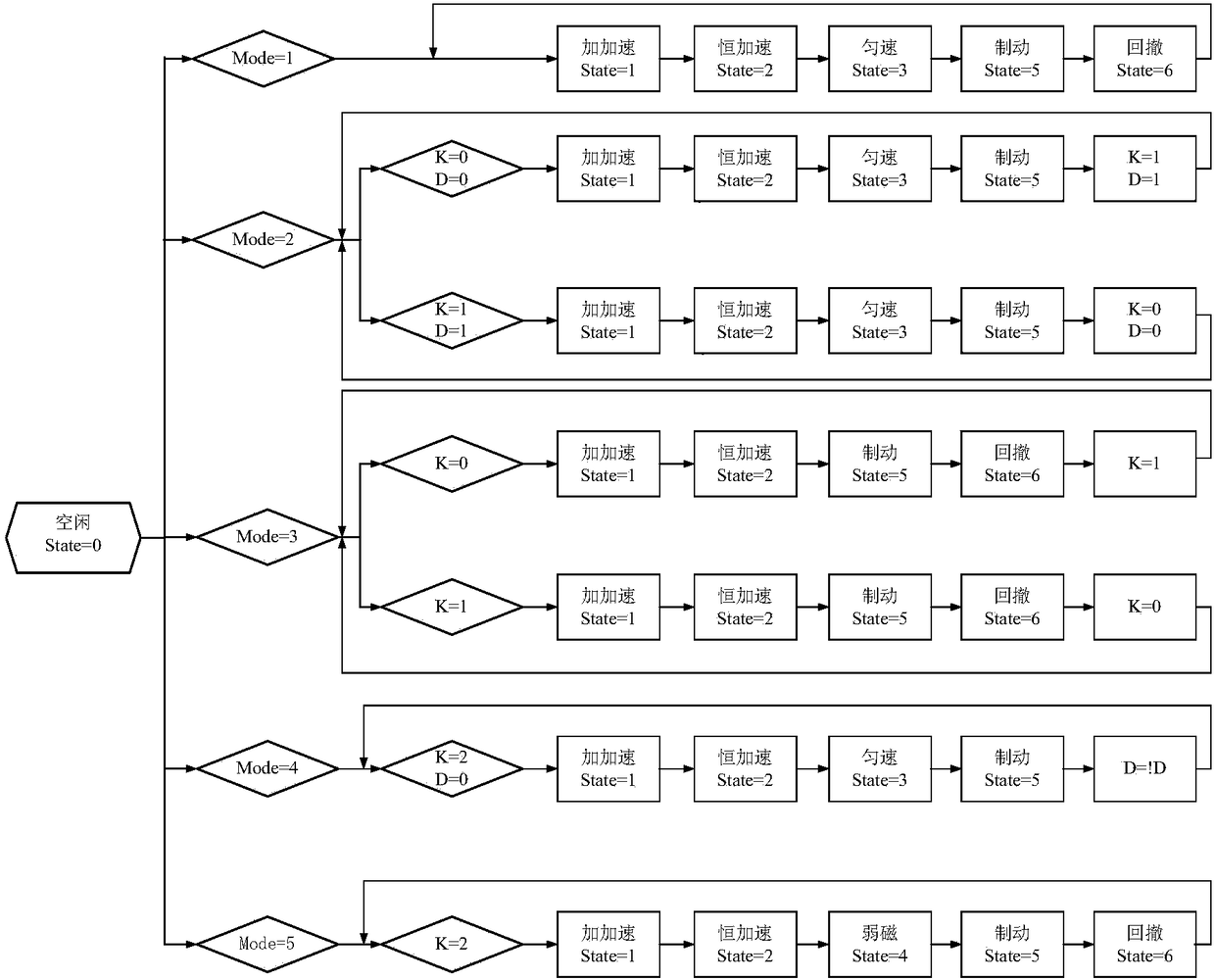

[0060] System operating modes include:

[0061] System check: The motor running speed is 1m / s, and the dual energy chains run at the same time. The motor running includes idle state, jerk state, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com