Tire with self-inflation device

A self-inflating, tire technology, used in tire measurement, tire parts, tire sidewalls, etc., can solve the problems of reduced durability of the tube 4, complex structure, difficult miniaturization, etc., to minimize the decrease in durability and enhance Noise performance, overall size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

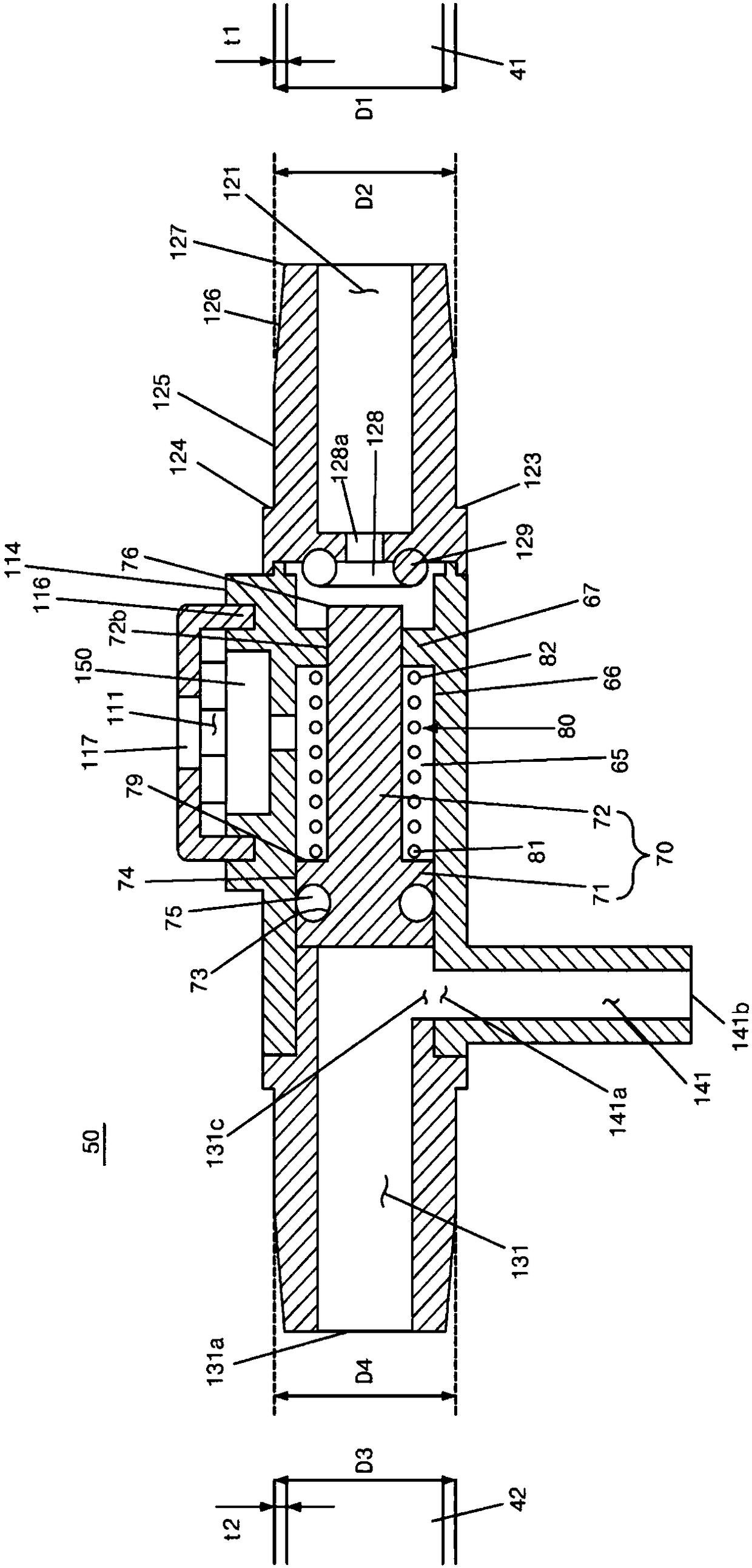

[0076] In the following, the regulator 50 will be described first as a focus.

[0077] The tire 10 of the present invention includes side portions.

[0078] The tube 40 is provided on the outside of the side portion 15 .

[0079] As the tire 10 is driven, as a telescoping movement takes place in the side 15 , a corresponding other telescoping movement takes place in the tube 40 provided in the side 15 .

[0080] The injection of air into the tire cavity 19 due to this telescopic movement in the side portion 15 and tube 40 will be described later.

[0081] The above-mentioned pipe 40 is connected to a regulator 50 .

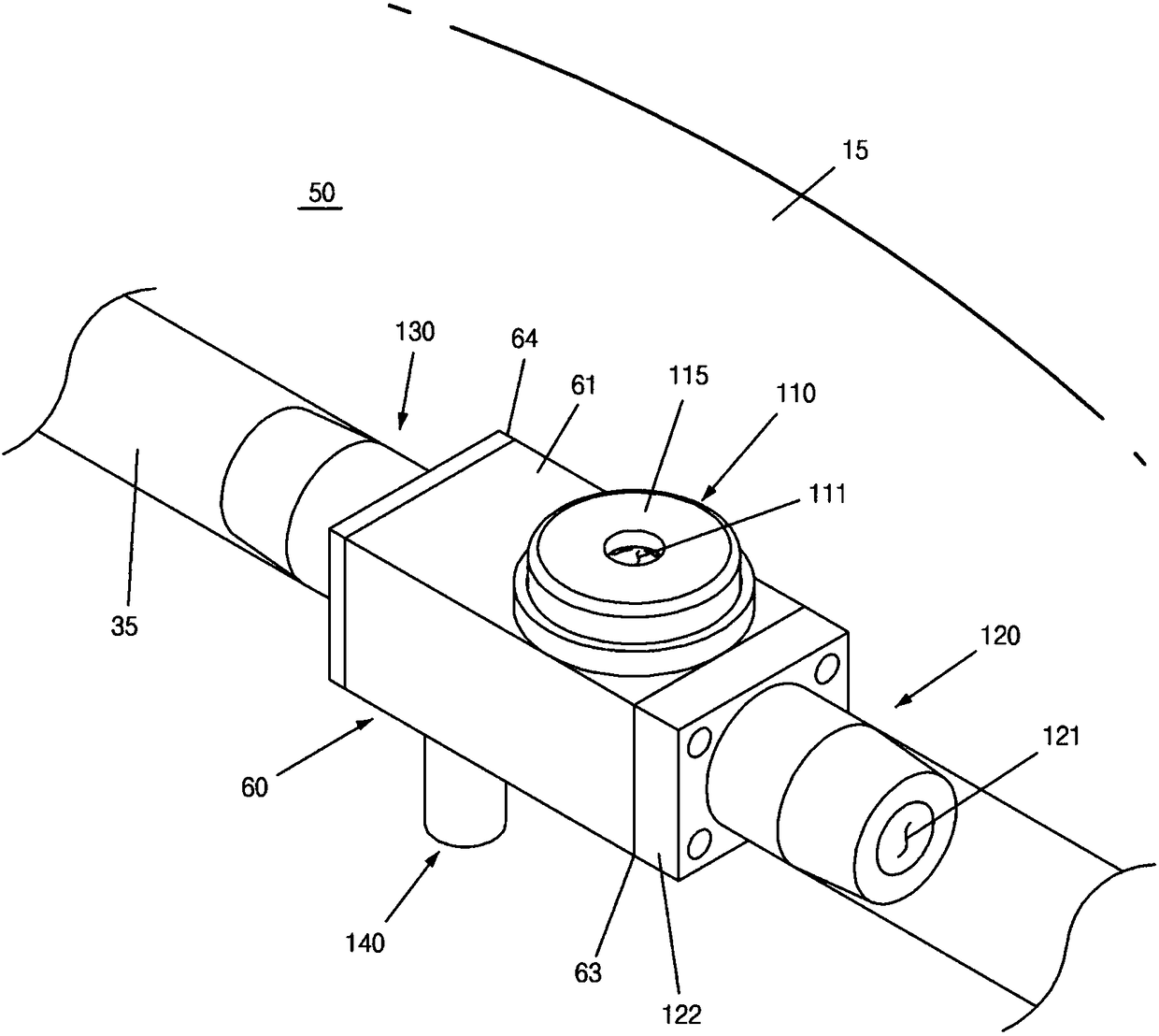

[0082] In the following, reference will be made to Figure 1 to Figure 3 The regulator 50 is described.

[0083] The overall shape of the adjuster 50 of the present invention is as follows.

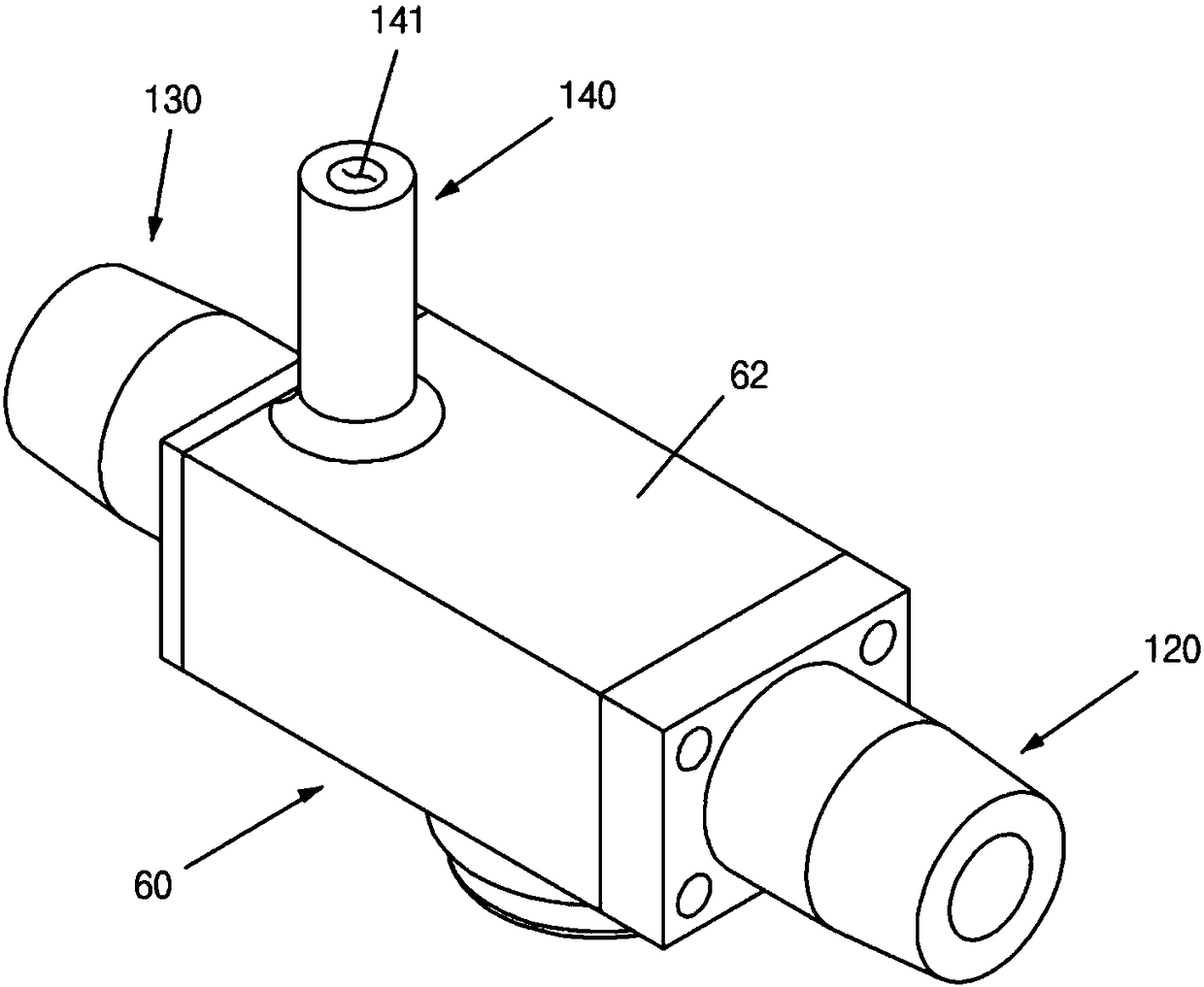

[0084] The regulator 50 includes a body 60 .

[0085] In the main body 60, a plurality of ports 110, 120, 130, and 140 are formed to protrude from the upper side, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com