Detection system and detection method for oil replacement of ship

A detection system and ship technology, applied in radio wave measurement system, satellite radio beacon positioning system, measurement device, etc., can solve the problem of inability to detect whether low-sulfur oil is used in ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

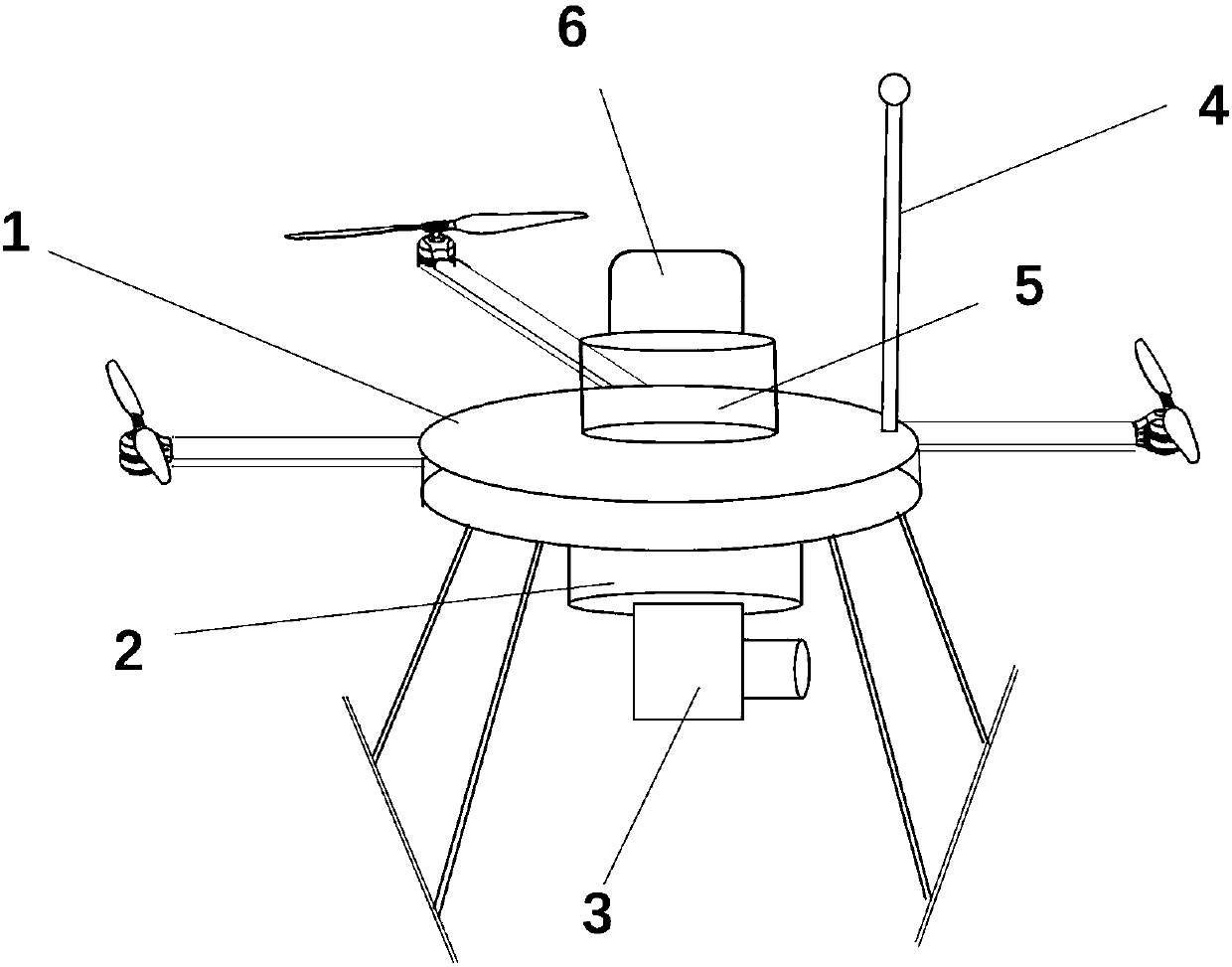

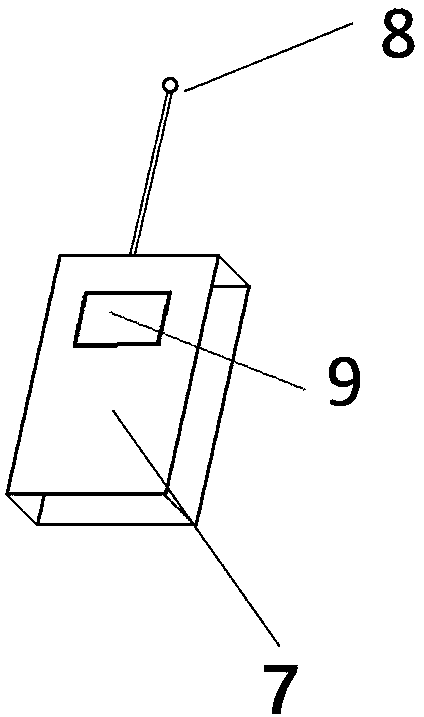

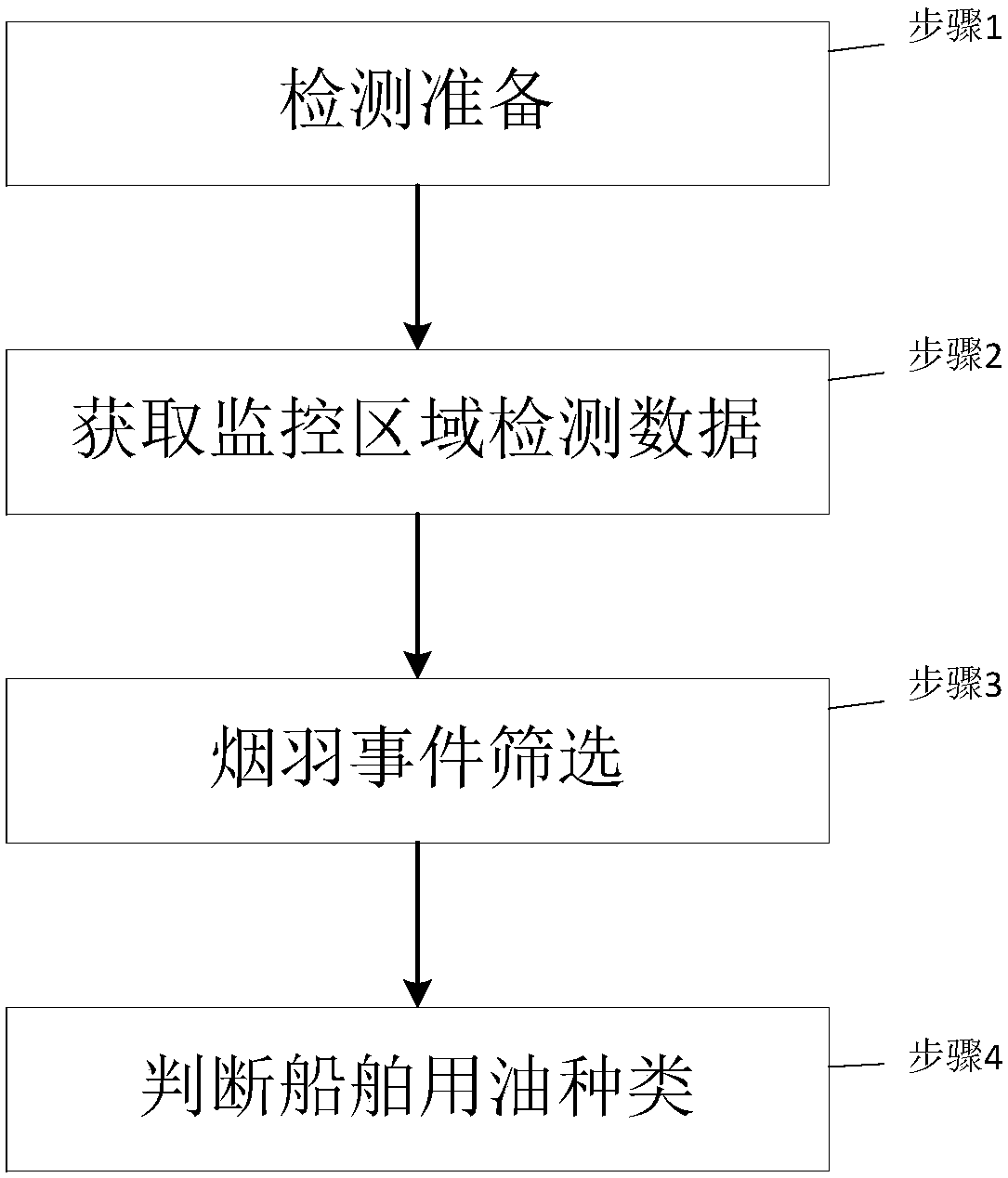

[0062] Example 1, such as figure 1 As shown, a ship oil change detection system includes:

[0063] Aerial detection unit: it includes a low-altitude tracking detection platform 1 and a first wireless communication module 4 fixed on the low-altitude tracking detection platform 1, a data processing storage module 2, a detection module 6, a tracking camera 3, a first wireless communication module 4 and The detection module 6 is connected with the data processing storage module 2, and the data processing storage module 2 is connected with the low-altitude tracking detection platform 1, and the detection module 6 includes a NO connected with the data processing storage module 2. x sensor, O 3 sensor and SO 2 Sensor; the tracking camera 3 is located below the low-altitude tracking detection platform 1 , and the tracking camera 3 is connected to the data processing and storage module 2 . A position sensor, which is fixed on the low-altitude tracking detection platform 1, and is co...

Embodiment 2

[0071] Embodiment 2 is different from the ship oil change detection system described in the first embodiment in that the first wireless communication module 4, the data processing and storage module 2, the detection module 6, the tracking camera 3 and the power supply module 5 are fixed on On the other hand, compared with the first embodiment, this embodiment will reduce the detection efficiency.

Embodiment 3

[0072] Embodiment 3, the difference from the ship oil change detection system described in the first embodiment is that the detection module 6 is composed of CO 2 Sensor instead of NO x sensor, compared with the first embodiment, this embodiment uses CO 2 The concentration data of the sensor is used as the fitting parameter, because the CO in the air 2 Larger concentrations and larger differences between different regions will lead to increased uncertainty in the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com