Manufacturing method of color filtering substrate

A technology of color filter substrate and manufacturing method, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as difficulties, achieve the effects of reducing work difficulty, shortening observation and measurement and time, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

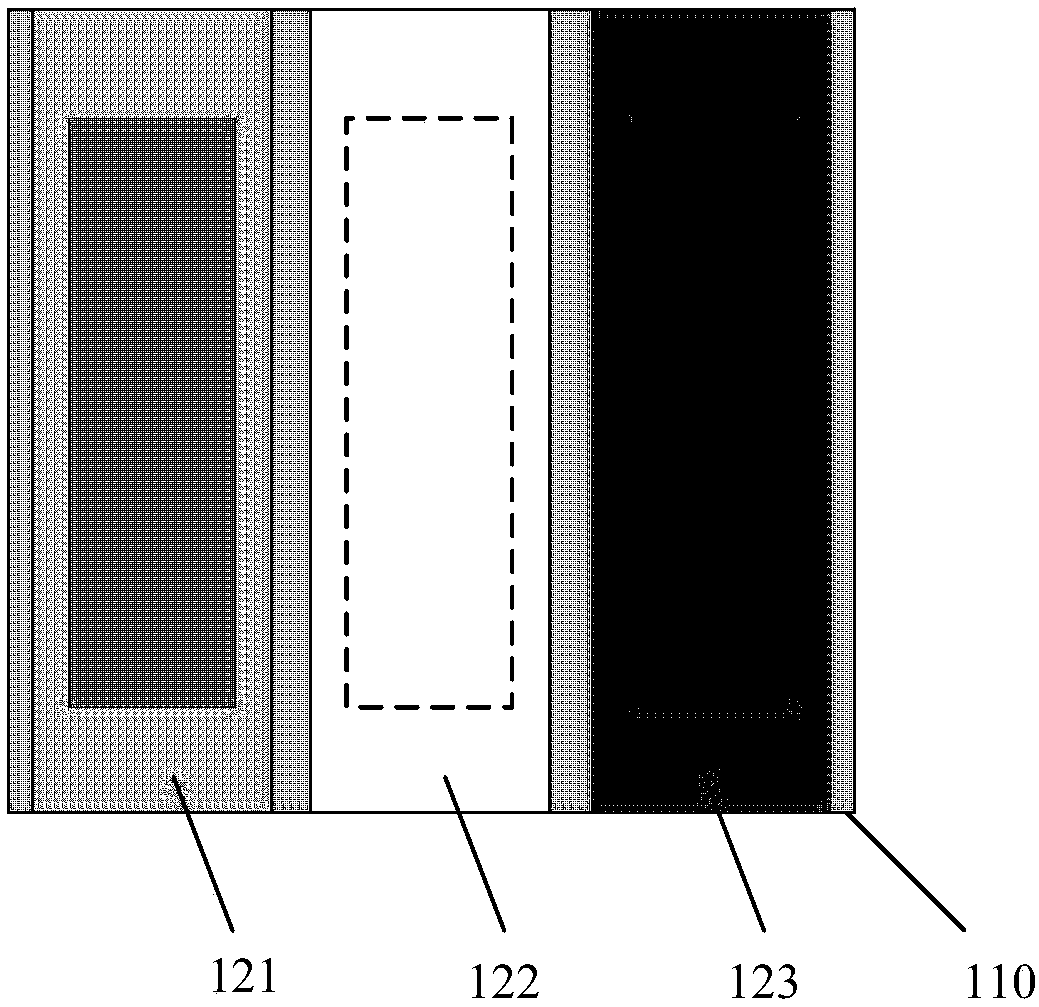

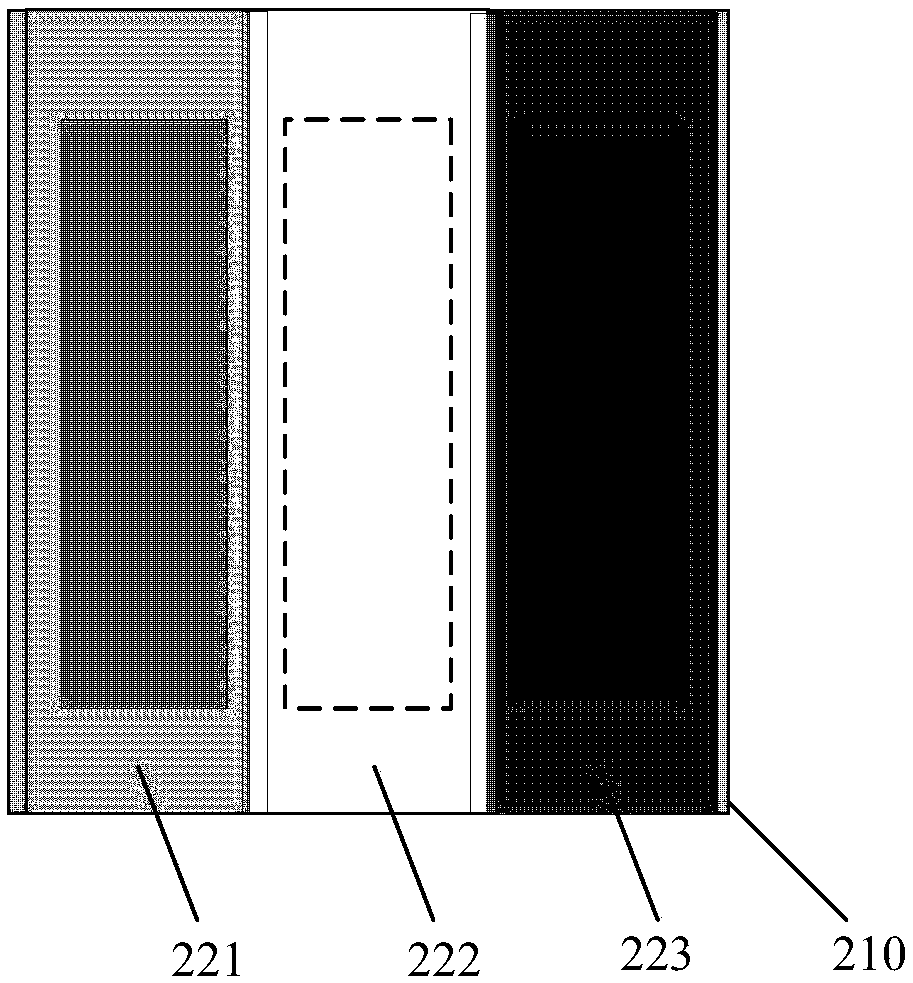

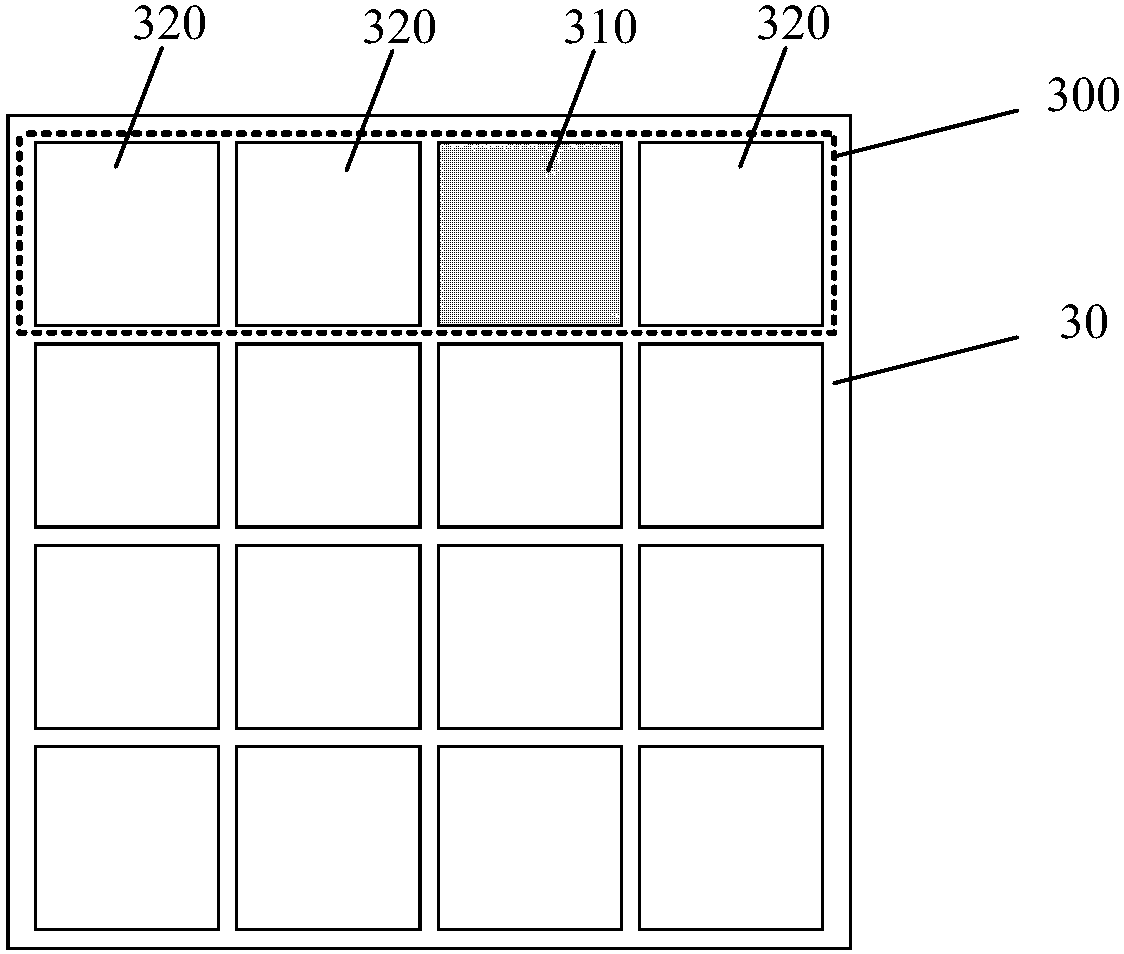

[0024] The functional structure on the color filter substrate usually includes a black matrix layer, a color sub-pixel color resist layer, a flat layer, and spacer columns. Among them, the color sub-pixel color resistance layer usually includes the color sub-pixel color resistance layer of the three primary colors of red, green and blue (RGB), that is, the color sub-pixel color resistance layer includes a red sub-pixel color resistance layer, a green sub-pixel color resistance layer and a blue sub-pixel color resistance layer. Pixel color resist layer. Sometimes the color sub-pixel color resistance layer may also include a white sub-pixel color resistance layer. The red sub-pixel color resistance layer, the green sub-pixel color resistance layer and the blue sub-pixel color resistance layer (sometimes including the white sub-pixel color resistance layer) are usually located in the same layer.

[0025] The red sub-pixel color resistance layer includes a plurality of red sub-pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com