Negative type photosensitive resin composition for black matrix, black matrix, color filter, and liquid crystal display element

A technology of photosensitive resin and black matrix, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment. It can solve the problems of developing residue and poor adhesion, and achieve the improvement of developing residue and poor adhesion. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example A-1-1

[0168] Into a flask equipped with a stirring device, a dropping funnel, a condenser, a thermometer, and a gas introduction tube, 262.0 g of propylene glycol monomethyl ether acetate (PGMEA) was added, stirred while replacing nitrogen, and the temperature was raised to 120°C.

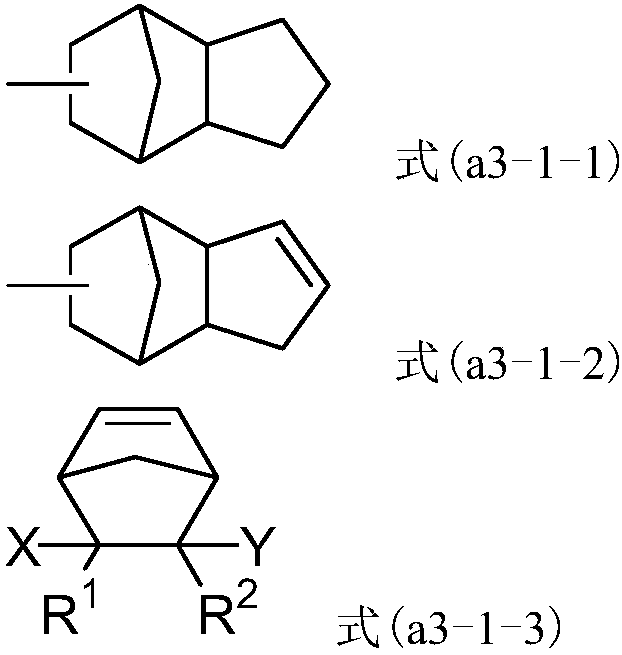

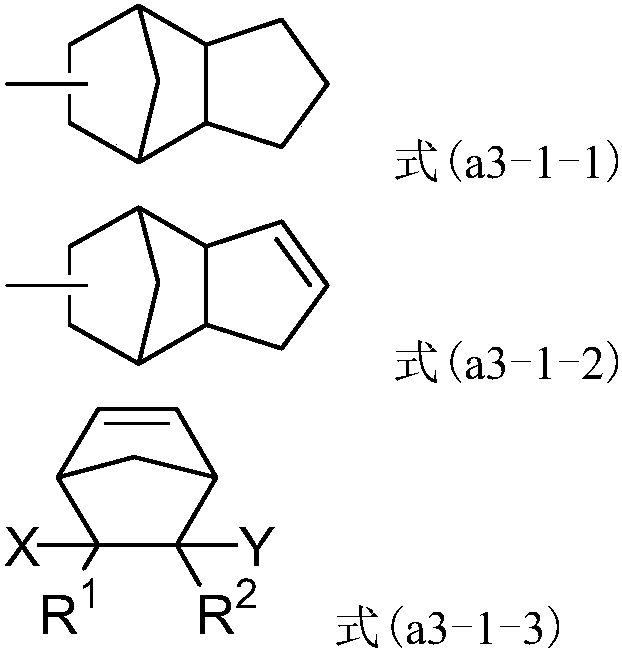

[0169] Next, in a mixture of isopropyl acrylate 5.70g (0.05 mole), glycidyl methacrylate 121g (0.85 mole), dicyclopentanyl methacrylate 13.2g (0.06 mole) and methyl methacrylate 4.00g (0.04 mol) to the monomer mixture composed of 19.0 g of tert-butylperoxy-2-ethylhexanoate (polymerization initiator, manufactured by NOF Corporation, Perbutyl O), and the resulting It was added dropwise to the aforementioned flask over 2 hours. After completion of the dropwise addition, stirring was carried out at 120° C. for 2 hours to conduct a copolymerization reaction to produce an addition copolymer. Then, the inside of the flask was replaced with air, and 73.2 g (0.85 mol) of methacrylic acid, 0.6 g of triphenylphosp...

Synthetic example A-2-1

[0175] Into a flask equipped with a stirring device, a dropping funnel, a condenser, a thermometer, and a gas introduction tube, 262.0 g of propylene glycol monomethyl ether acetate (PGMEA) was added, stirred while replacing nitrogen, and the temperature was raised to 120°C.

[0176] Secondly, by α-methylstyrene 45.8g (0.16 mol), glycidyl methacrylate 107g (0.75 mol), dicyclopentenyl oxygen ethyl methacrylate 18.5g (0.07 mol) and In the monomer mixture that bornene 1.88g (0.02 mole) forms, add the tertiary butylperoxy-2-ethylhexanoate of 19.0g (polymerization initiator, NOF company manufacture, PerbutylO), the gained Those were added dropwise to the aforementioned flask from the dropping funnel over 2 hours. After completion of the dropwise addition, stirring was carried out at 120° C. for 2 hours to conduct a copolymerization reaction to produce an addition copolymer. Then, the inside of the flask was replaced with air, and 50.4 g (0.7 mol) of acrylic acid, 0.6 g of triphenylp...

Synthetic example A-3-1

[0188] Into a flask equipped with a stirring device, a dropping funnel, a condenser, a thermometer, and a gas introduction tube, 267.5 g of propylene glycol monomethyl ether acetate (PGMEA) was added, stirred while replacing nitrogen, and the temperature was raised to 120°C.

[0189] Next, by 55.3g (0.3 mole) of 2-ethylhexyl acrylate, 17.2g (0.2 mole) of methacrylic acid, 11.0g (0.05 mole) of dicyclopentyl methacrylate, 25.0g (0.05 mole) of methyl methacrylate ( 0.25 mol) and benzyl methacrylate 35.2g (0.2 mol) monomer mixture, add 19.2g of tertiary butyl peroxy-2-ethylhexanoate (polymerization initiator, NOF Preparation, Perbutyl O), the resultant was added dropwise to the aforementioned flask from the dropping funnel over 2 hours. After completion|finish of dripping, it stirred at 120 degreeC for 2 hours, and performed copolymerization reaction, and obtained another alkali-soluble resin (A-3-1).

[0190] Examples and Comparative Examples of Negative Photosensitive Resin Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap