Calculation method for cutter torque of composite shield machine in rock and soil mixing geology tunneling

A technology of cutter head torque and calculation method, which is applied in calculation, special data processing applications, instruments, etc., can solve problems such as the friction torque of mixed geology without considering the geology, and achieve the effect of accurate and reliable calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

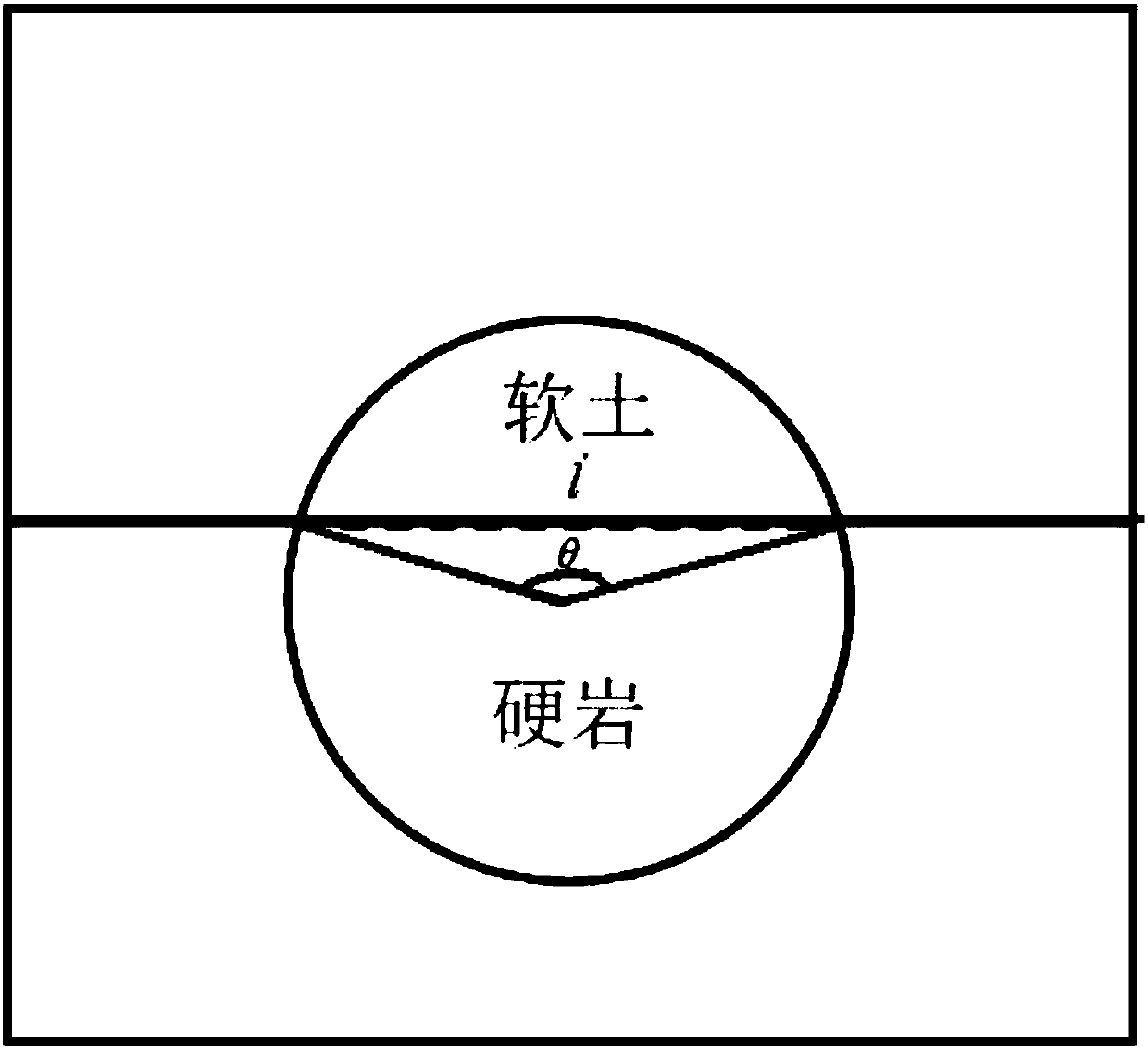

[0039] The calculation method of the cutter head torque of the composite earth pressure balance shield of the present invention in rock-soil mixed geological excavation will be described in detail below in conjunction with the embodiments and the drawings.

[0040] The method for calculating the torque of the cutter head of the composite earth pressure balance shield in rock-soil mixed geological tunneling of the present invention includes the following steps:

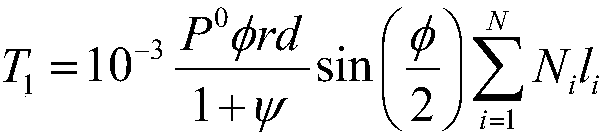

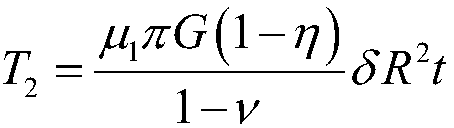

[0041] 1) Calculate the torques as follows:,

[0042] Torque T generated by the hob breaking rock 1 , The contact part of the cutter head panel and the soft soil layer is squeezed by tunneling to produce friction torque T 2 , The friction torque T of the contact part between the cutter head panel and the soft soil layer caused by the buried depth of the overburden 3 , The stratum resistance torque T of the cutterhead cutting soil 4 , Friction torque T between the side of the cutter head and the soft soil 5 , Friction torque T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com