Mechanical servo control method for axial-flow threshing

A technology of mechanical servo and control method, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as unfavorable storage, increase labor intensity, waste manpower and time, reduce electricity and labor costs, and ensure threshing. Work effect, achieve consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

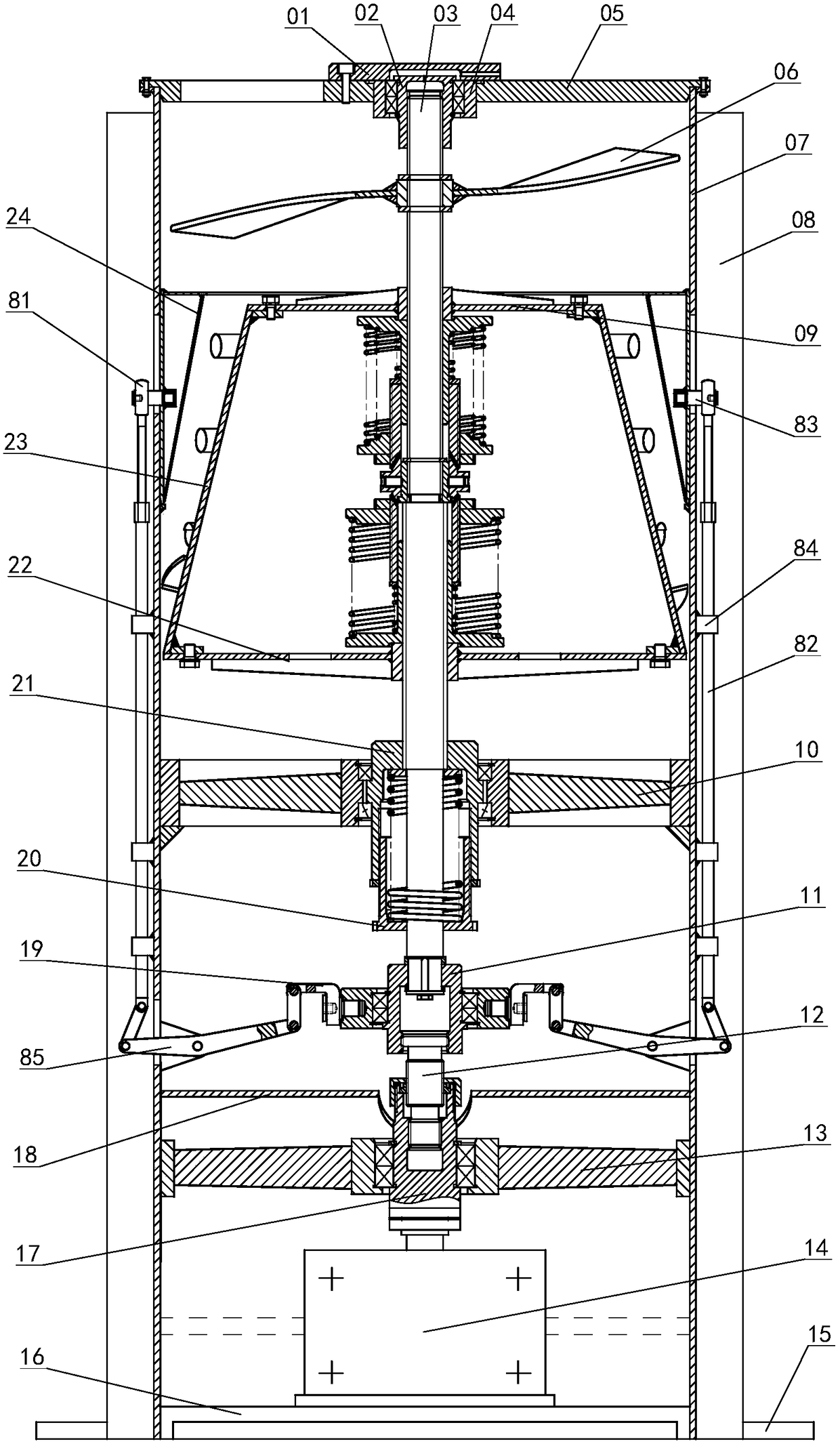

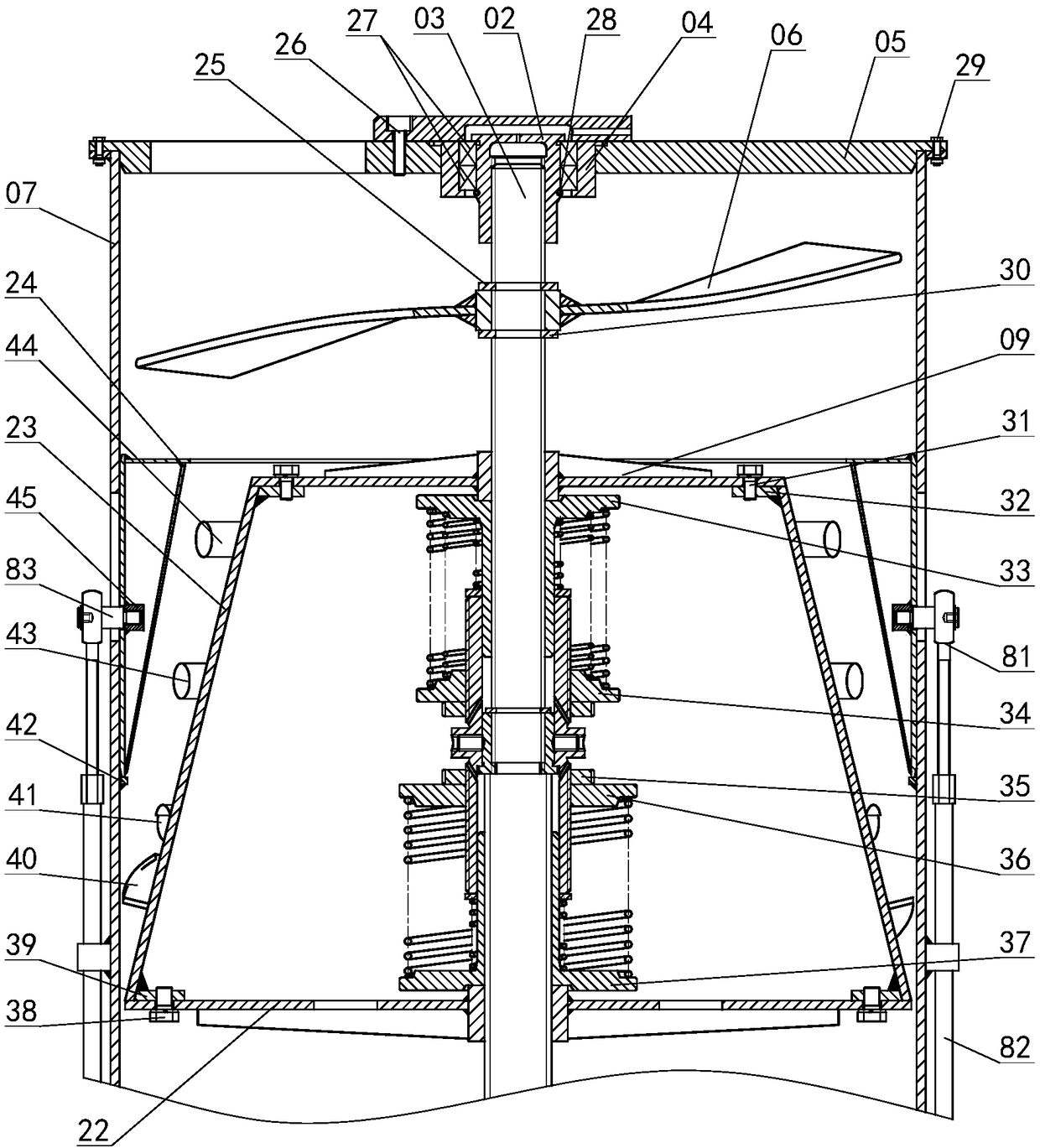

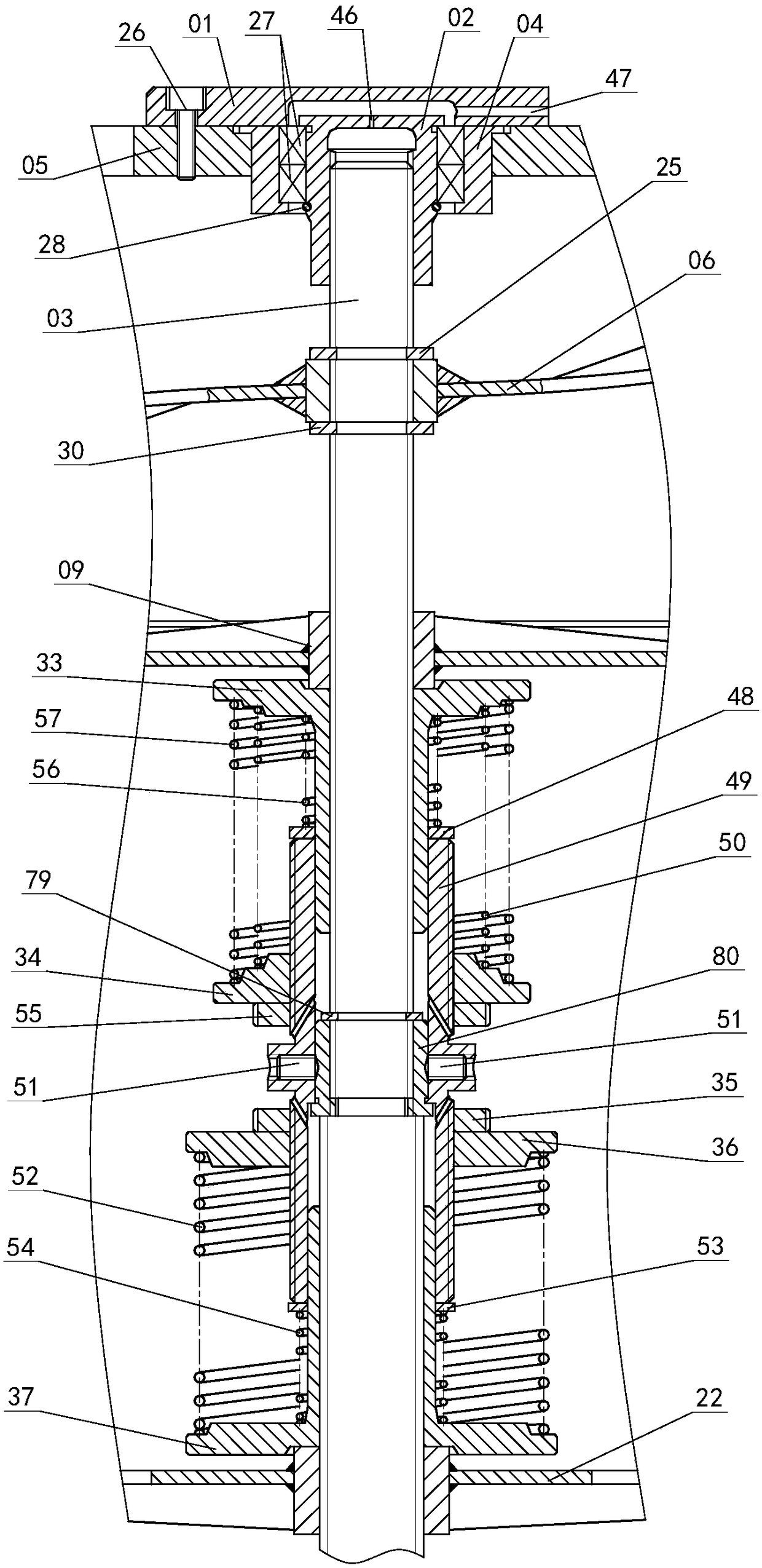

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0033] see Figure 1 to Figure 6 The mechanical servo control method for axial flow threshing uses an axial flow thresher with servo feedback control function to implement threshing operations. The axial flow thresher with servo feedback control function includes the first bearing end cover 01, The first spline sleeve 02, the first transmission shaft 03, the first bearing seat 04, the upper hatch cover 05, the rotating blade 06, the main cabin body 07, the cabin auxiliary bracket 08, the upper cover of the roller 09, the middle power bracket 10, Transmission control spline sleeve 11, transmission control spline shaft 12, lower power bracket 13, motor 14, bracket foot iron 15, motor seat 16, second transmission shaft 17, inclined blanking plate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com