Filler gluten and preparation method thereof

A gluten and wheat flour technology, applied in the field of gluten, can solve problems such as insufficient gluten oil absorption, shorten product shelf life, unhealthy gluten food, etc., and achieve the effect of improving hard taste, uniform and loose internal network structure, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

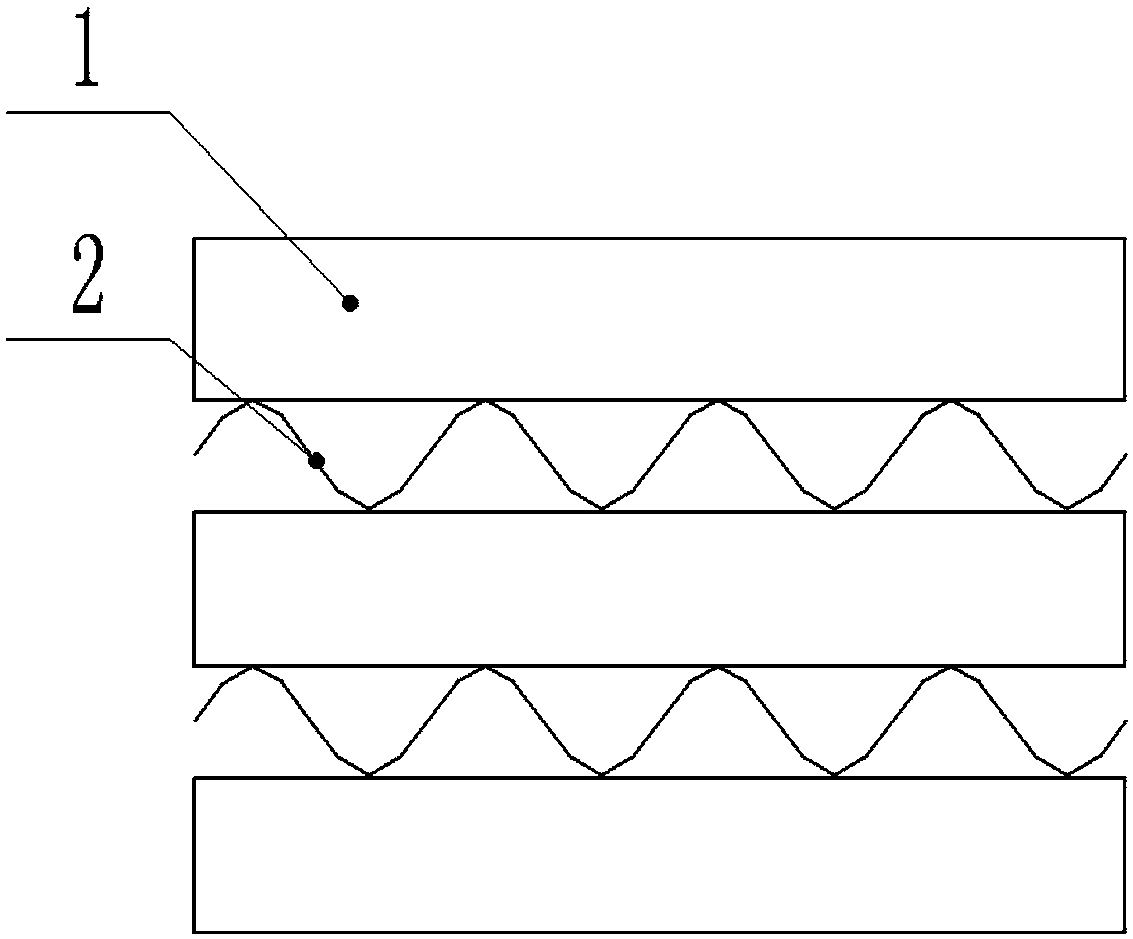

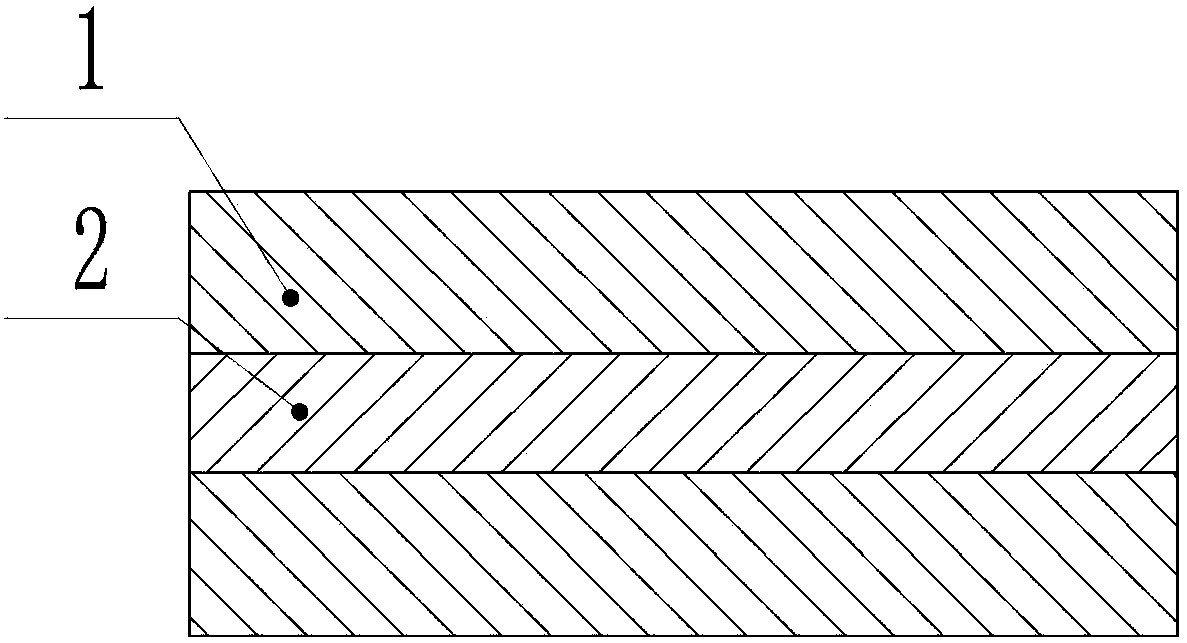

[0041] A filler gluten, comprising gluten 1 and filler 2. The gluten comprises the following components in parts by weight: 20 parts of wheat flour, 2.3 parts of salted duck egg white powder, 2 parts of lipid mixed powder, 0.23 parts of compound modifier, and salt 1.2 parts, 0.04 parts of sucralose, 1 part of fructose powder, 10 parts of compound seasoning.

[0042] The filling gluten is a sandwich type; the filling includes strawberry jam, mango jam, apple sauce, and chocolate sauce.

[0043] In terms of weight percentage, the grain size distribution of the wheat flour is: 1.5% with a particle size greater than 69 mesh; 1.8% with a particle size of 69-76 mesh; 3.8% with a particle size 76-91 mesh; 4.3% with a particle size of 91-107 mesh; 88.6 with a particle size smaller than 107 mesh %;

[0044] The wheat flour indicators are: gluten content 24%; ash content 0.7%; formation time 1.5min; stabilization time 3.5min; weakening degree 40FU; stretching energy 40cm2; elongation 90mm; ma...

Embodiment 2

[0062] A filler gluten, comprising gluten 1 and filler 2, the gluten comprising the following components in parts by weight: 22 parts of wheat flour, 2.5 parts of salted duck egg white powder, 2.3 parts of lipid mixed powder, 0.25 parts of compound modifier, table salt 1.6 parts, 0.06 parts of stevioside, 1.2 parts of fructose powder, 12 parts of compound seasoning.

[0063] The filling gluten is in a sandwich type; the filling includes mango sauce, apple sauce, chocolate sauce, and coffee sauce.

[0064] In terms of weight percentage, the grain size distribution of the wheat flour is: 1.4% with a particle size greater than 69 mesh; 1.7% with a particle size of 69-76 mesh; 3.7% with a particle size of 76-91 mesh; 3.4% with a particle size of 91-107 mesh; 89.8 with a particle size of less than 107 mesh %;

[0065] The wheat flour indicators are: gluten content 27%; ash content 0.9%; formation time 2min; stabilization time 6min; weakening degree 80FU; stretching energy 80cm2; elongati...

Embodiment 3

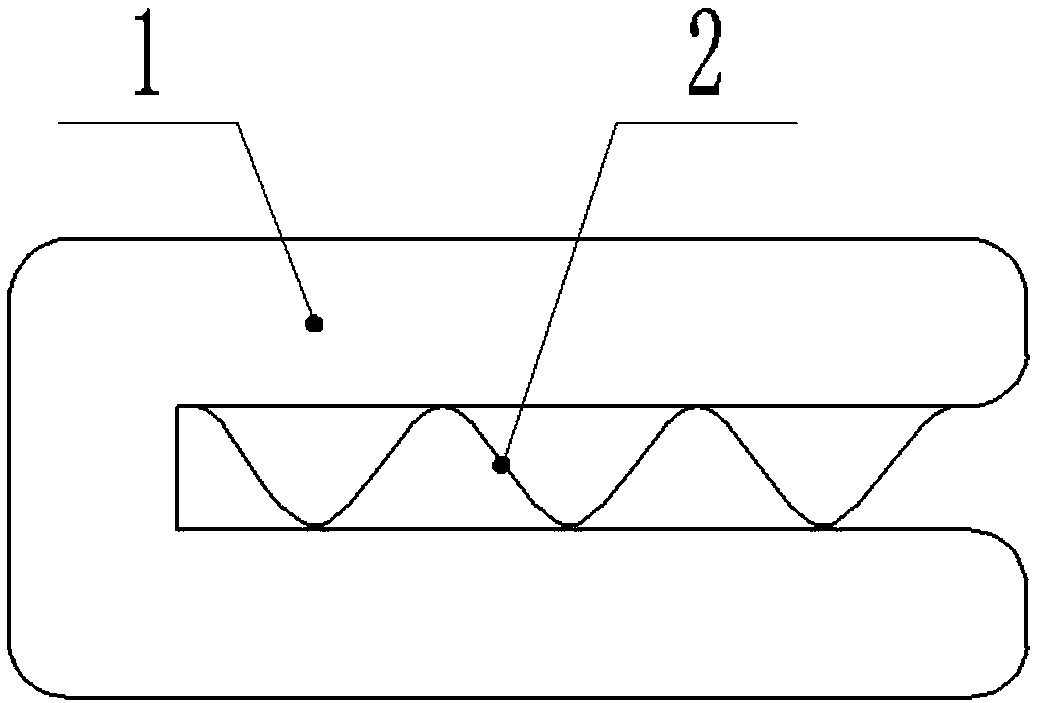

[0083] A filler gluten, comprising gluten 1 and filler 2. The gluten comprises the following components in parts by weight: 21 parts of wheat flour, 2.4 parts of salted duck egg white powder, 2.2 parts of lipid mixed powder, 0.24 parts of compound modifier, and salt 1.5 parts, 0.05 parts of sucralose, 1.15 parts of fructose powder.

[0084] The filling gluten is a core-filled type; the filling is a mixture of chocolate sauce, coffee sauce and pork floss.

[0085] In terms of weight percentage, the grain size distribution of the wheat flour is: 1.3% with a particle size greater than 69 mesh; 1.7% with a particle size of 69-76 mesh; 3.7% with a particle size 76-91 mesh; 4.3% with a particle size of 91-107 mesh; 89 with a particle size smaller than 107 mesh %;

[0086] The wheat flour indicators are: gluten content 25%; ash content 0.8%; formation time 1.8min; stabilization time 5min; weakening degree 60FU; stretching energy 60cm 2 ; Elongation 100mm; maximum tensile resistance 500EU; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com