Dropping and distilling reaction device

A reaction device and dripping technology, which is applied in the directions of feeding device, distillation separation, steam condensation, etc., can solve the problems of explosive boiling, collision between distillation tank and heating furnace, and difficulty in controlling dripping speed, etc. The effect of smooth output, avoidance of bumping, and reduced agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

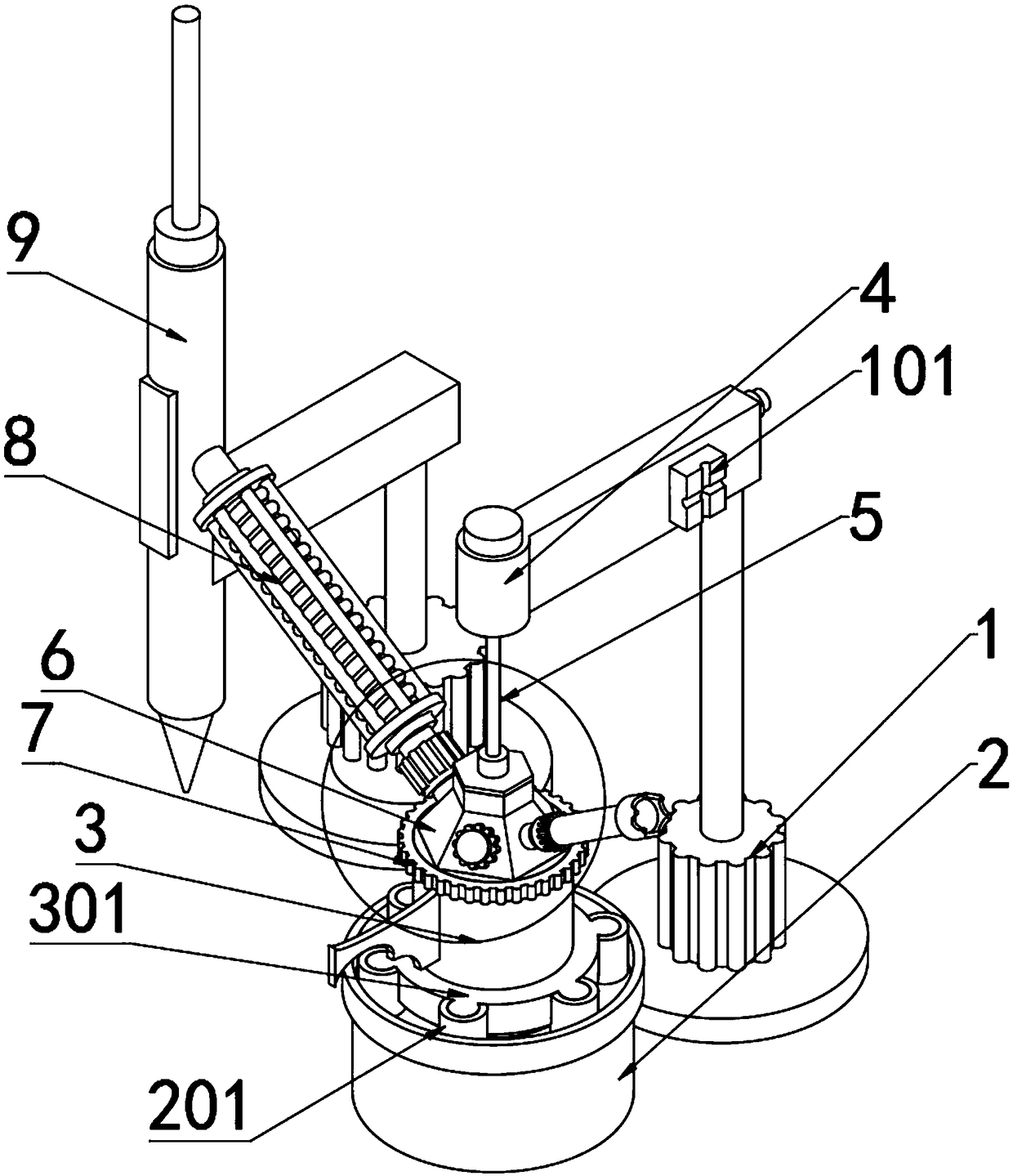

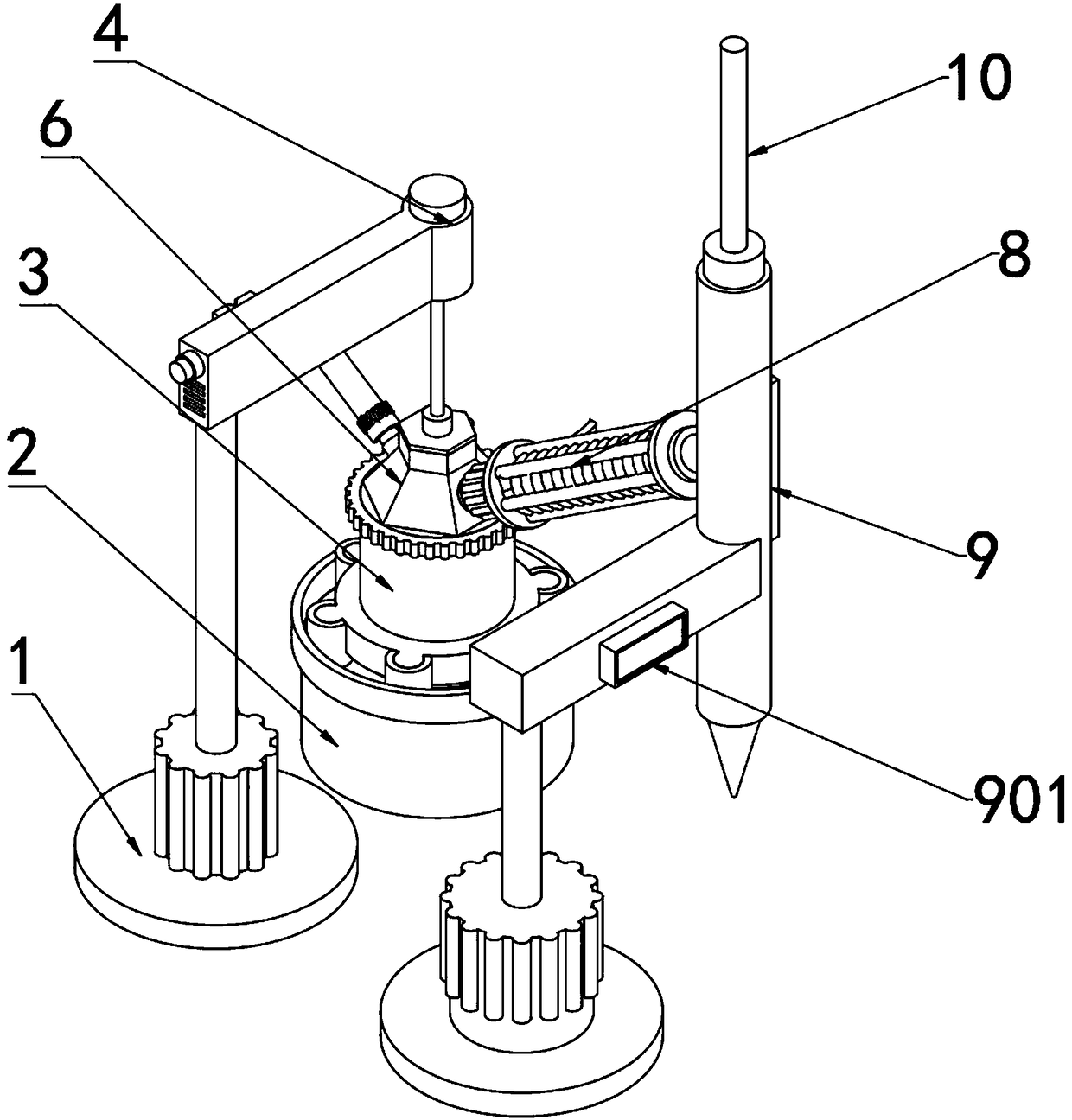

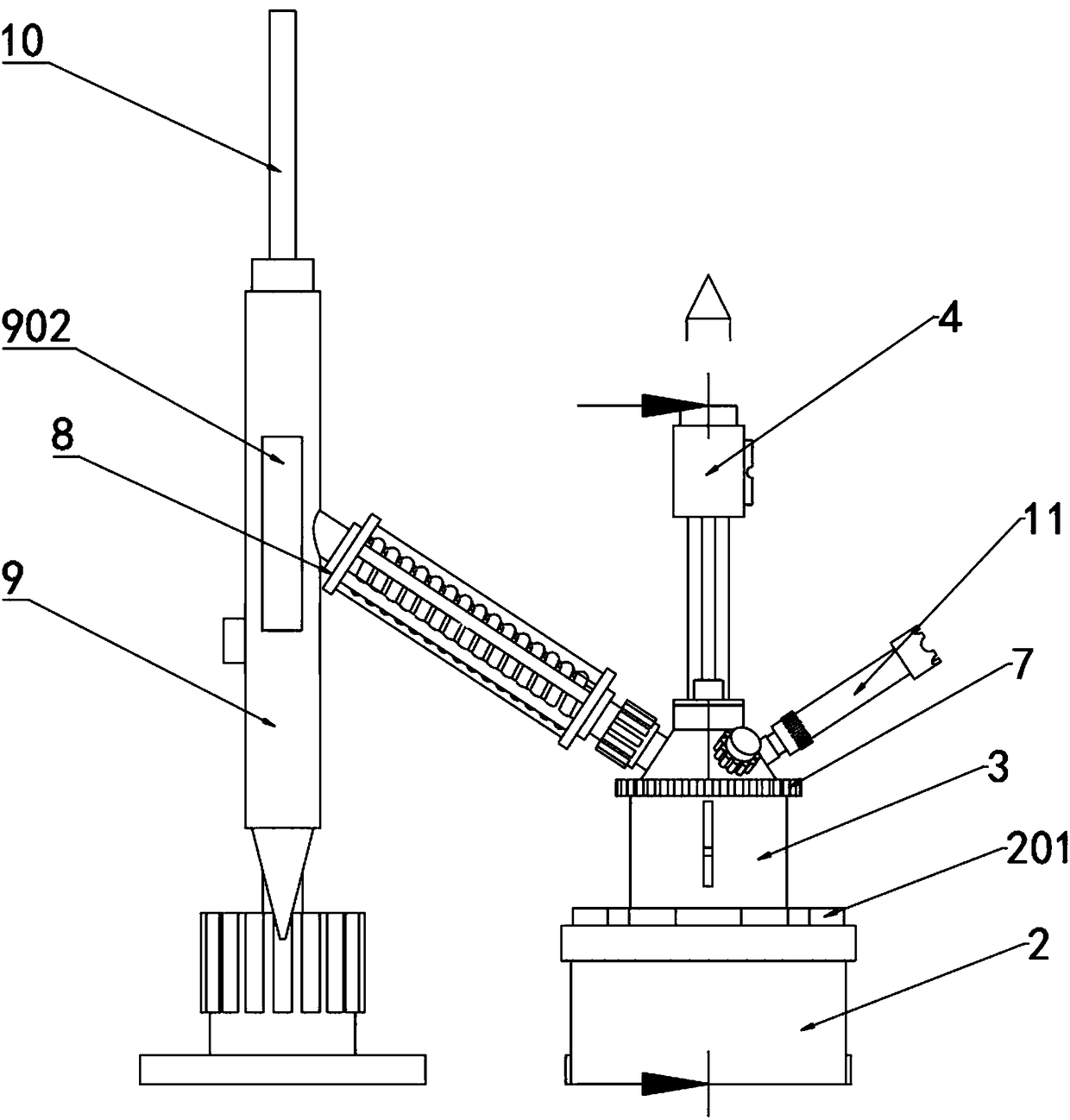

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035]The present invention provides a dripping and distilling reaction device, comprising a stand 1, a heating pot 2, a distillation tank 3, an electromagnetic stirrer 4, a connecting rod 5, an upper cover 6, a spiral sealing disc 7, a condenser 8, a distiller 9, Temperature detector 10, dropper 11, stirring paddle 12, anti-boiling ring 13, buffer 14, control panel 101, deck 201, deck 301, injection port 601, coil tube 801, solid tube 802, screw Joint 803, temperature display 901, window 902, flat plate 1201, anti-boiling ball 1301 and deflector 1401, the control panel 101 is fixedly attached to the upper and outer surface of the top cross bar of the bench 1, and the cross bar of the bench 1 The front end is fixedly provided with an electromagnetic stirrer 4 electrically connected to the control panel 101; the reducer at the bottom of the electromagnetic stirrer 4 is rotatably connected with a connecting rod 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com