Automatic feeding device and method for garment manufacturing

An automatic material feeding and garment manufacturing technology, applied in the field of garment manufacturing, can solve the problems of heavy burden on workers and achieve the effects of flexible layout, high accuracy and sensitive detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

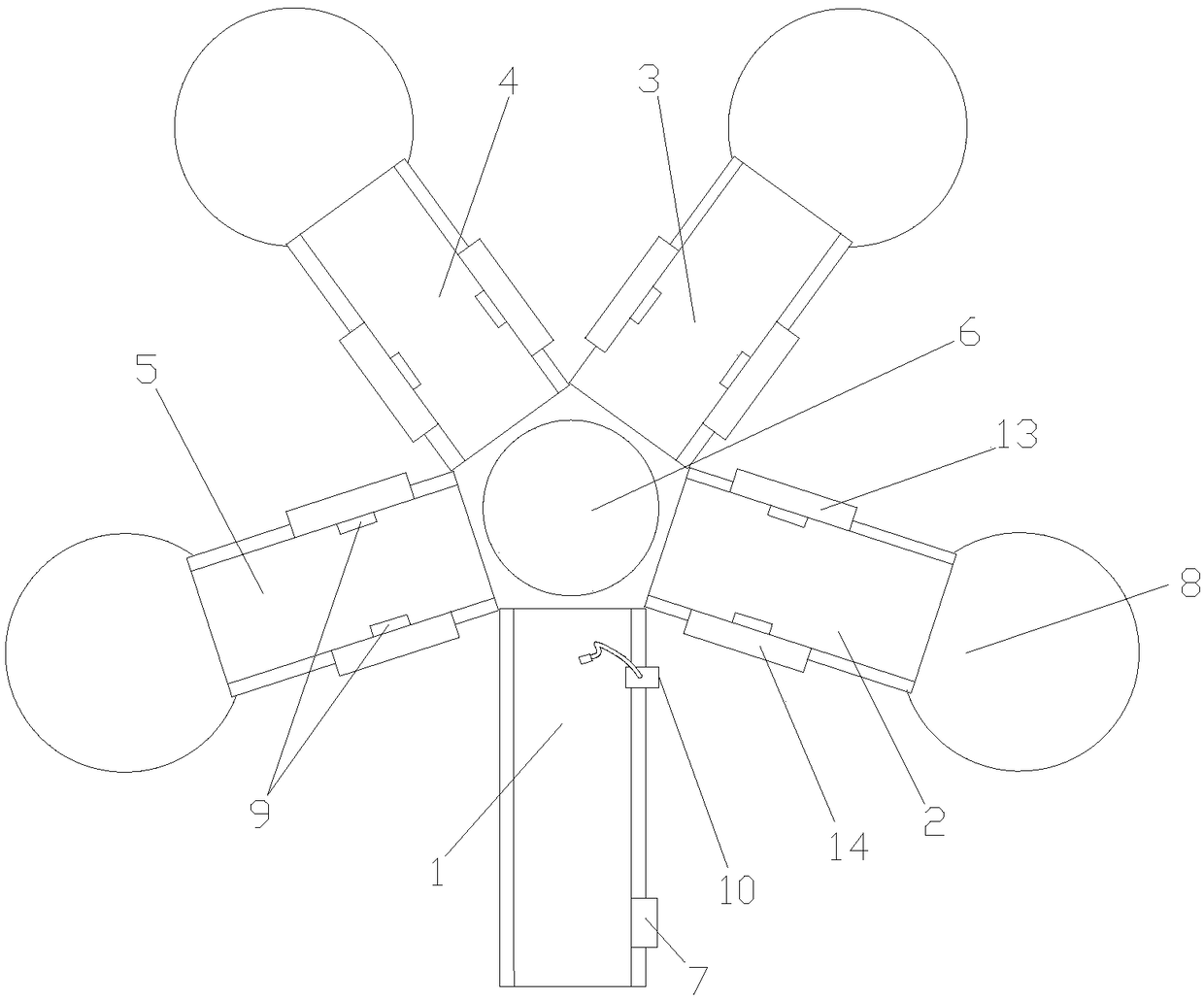

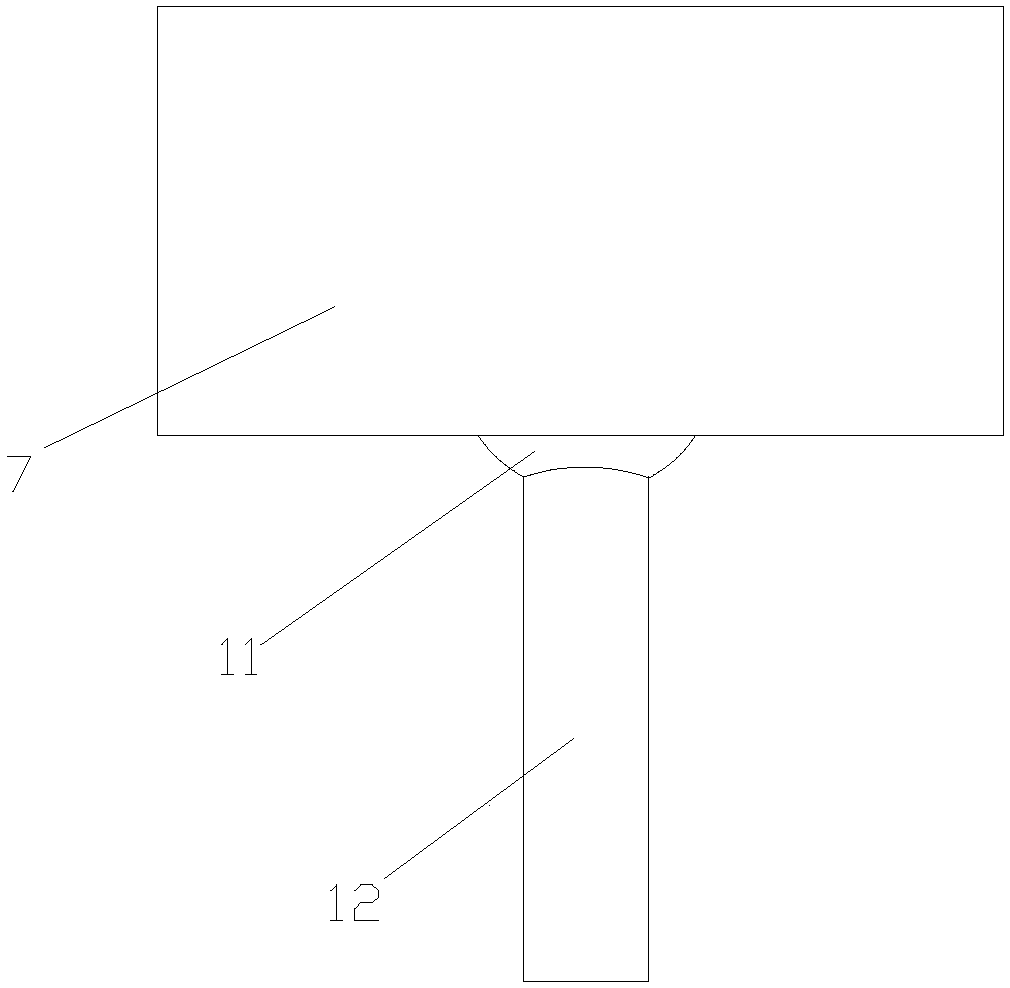

[0029] Such as Figure 1-2As shown, an automatic feeding device for garment manufacturing includes a first conveyor 1 for conveying mixed materials, a second conveyor 2 for conveying red materials, a third conveyor 3 for conveying green materials, The fourth conveyor 4 for conveying blue materials, the fifth conveyor 5 for manual sorting, the sorting device 6 and the control device 7, the second conveyor 2, the third conveyor 3, the fourth The ends of the conveyor 4 and the fifth conveyor 5 are all provided with a material cylinder 8, and the first conveyor 1, the second conveyor 2, the third conveyor 3, the fourth conveyor 4 and the fifth conveyor 5 are divided into The sorting device 6 is distributed in a circular array at the center point, and the head ends of the second conveyor 2, the third conveyor 3, the fourth conveyor 4, and the fifth conveyor 5 are all provided with a detection device 9 for detecting materials, so The end of the first conveyor 1 is provided with a c...

Embodiment 2

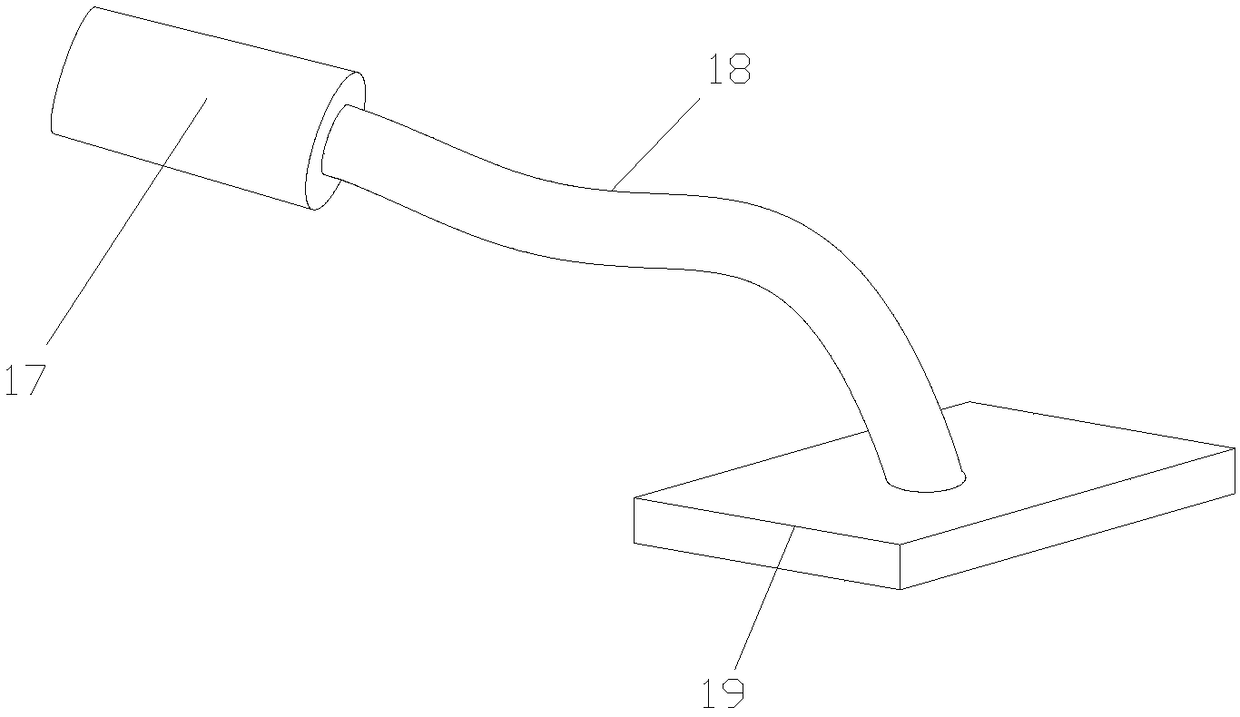

[0032] Such as Figure 1-5 As shown, an automatic feeding device for garment manufacturing includes a first conveyor 1 for conveying mixed materials, a second conveyor 2 for conveying red materials, a third conveyor 3 for conveying green materials, The fourth conveyor 4 for conveying blue materials, the fifth conveyor 5 for manual sorting, the sorting device 6 and the control device 7, the second conveyor 2, the third conveyor 3, the fourth The ends of the conveyor 4 and the fifth conveyor 5 are all provided with a material cylinder 8, and the first conveyor 1, the second conveyor 2, the third conveyor 3, the fourth conveyor 4 and the fifth conveyor 5 are divided into The sorting device 6 is distributed in a circular array at the center point, and the head ends of the second conveyor 2, the third conveyor 3, the fourth conveyor 4, and the fifth conveyor 5 are all provided with a detection device 9 for detecting materials, so The end of the first conveyor 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com