A swirling flow upper nozzle for continuous casting tundish

A continuous casting tundish and nozzle technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems such as difficult inert gas bubbles, complicated manufacturing and processing technology, and has not been applied, so as to reduce asymmetry The effect of fluctuation, easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

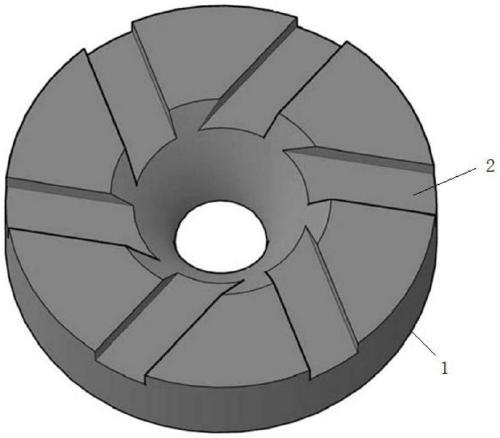

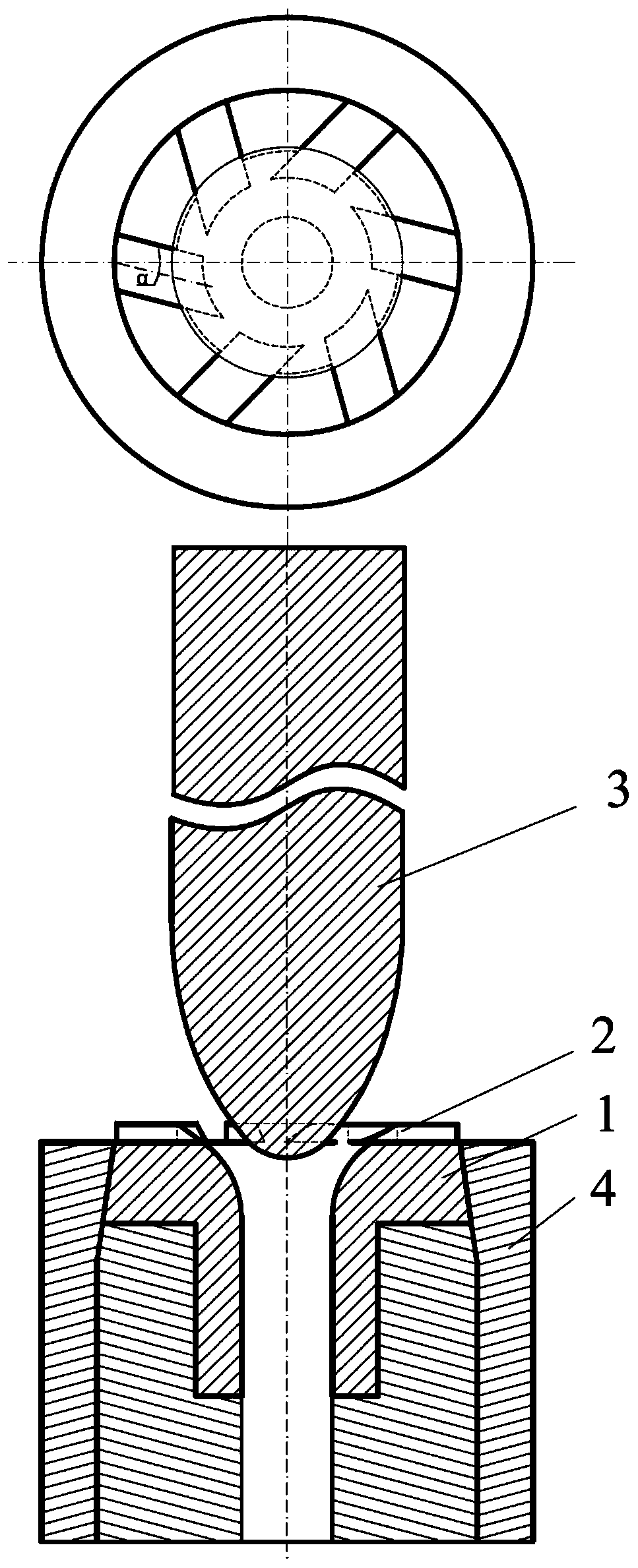

[0036] The tundish swirl upper nozzle provided by the present invention is used on the slab continuous casting machine, the upper nozzle 1 is about 20mm higher than the outlet block 4, the upper surface of the nozzle block 4 is flush with the bottom of the tundish, and the swirl groove 2 is provided It can reduce the amount of residual steel in the tundish. The whole structure is as figure 2 shown. figure 2 Among them, the inner diameter of the top of the upper nozzle 1 is 110mm, and the inner diameter of the bottom of the upper nozzle 1 is 50mm. The upper part of the upper nozzle 1 is provided with 6 centrally symmetrical swirl grooves 2, the groove width is 30mm, and the groove depth is 10mm. The angle α between them is 14°. Under the technological conditions of casting speed of 1.35m / min and slab section of 1235mm×175mm, the average downward flow velocity of molten steel in the nozzle is about 2.483m / s, and the distance from the lower end of the upper nozzle 1 arc is 5...

Embodiment 2

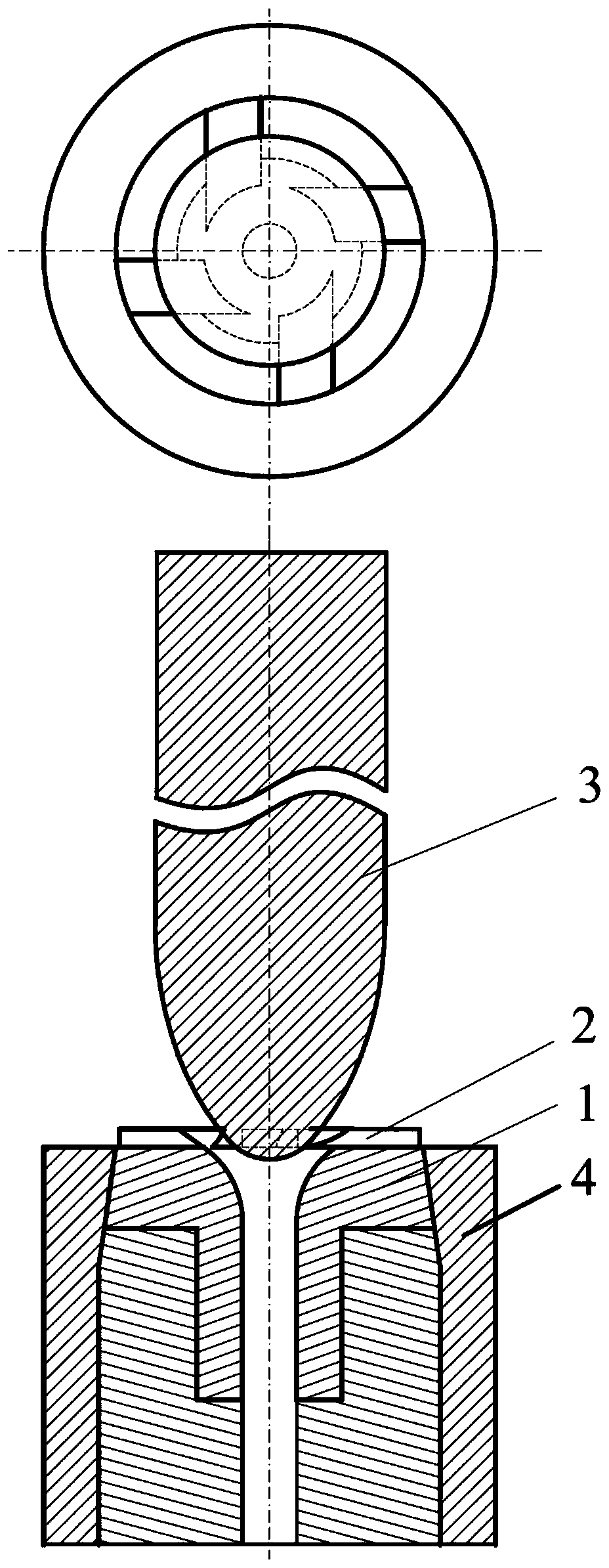

[0038] Use the tundish swirl upper nozzle provided by the present invention on the billet continuous casting machine, the upper nozzle 1 is about 20mm higher than the outlet block 4, the upper surface of the nozzle block 4 is flush with the bottom of the tundish, and the swirl groove 2 provided can be Reduce the amount of residual steel in the tundish. The whole structure is as image 3 shown. image 3Among them, the inner diameter of the top of the upper nozzle 1 is 90mm, and the inner diameter of the bottom of the upper nozzle 1 is 30mm. The upper part of the upper nozzle 1 is provided with 4 centrally symmetrical swirl grooves, the groove width is 30mm, and the groove depth is 10mm. The included angle α is 14°. Under the technological conditions of casting speed of 1.6m / min and billet section of 180mm×180mm, the average downward flow velocity of molten steel in the nozzle is about 1.223m / s. The swirling velocity is 0.096m / s, achieving a good swirling effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com