MBBR coupled ammoxidation integrated purification tank

A purification tank and ammonia oxidation technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water pollutants, etc., can solve problems such as non-growth, ineffective growth of activated sludge, unstable inflow and outflow, etc. Achieve the effect of fast film hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

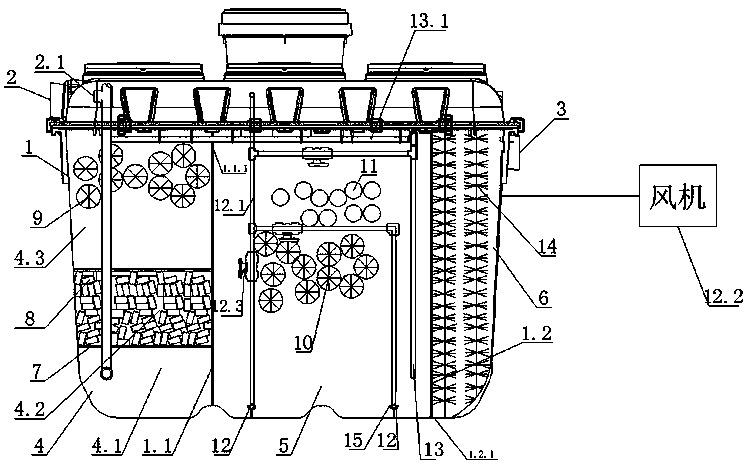

[0046] Embodiment 1: as figure 1As shown, an MBBR-coupled ammonia oxidation integrated purification tank includes a horizontal shell 1, a water inlet 2 and a water outlet 3 respectively opened on the horizontal shell 1, and two pieces of the horizontal shell 1 are arranged. The main partition, the first partition 1.1 and the second partition 1.2, divide the horizontal shell 1 into three sealed compartments, the first compartment 4 on the left is the anaerobic biological filter bed area, and the second compartment 5 in the middle is the MBBR area , the third compartment 6 on the right is an anaerobic biofilm area, and a water inlet 2 is arranged near the top of the anaerobic biofilter bed area. The top is provided with a water outlet 3, and the first chamber 4 is divided into three chambers by setting two mesh partitions 7 from bottom to top, which are the first-level anaerobic chamber 4.1, the second-level anaerobic biological filter bed chamber 4.2, and the third chamber. Th...

Embodiment 2

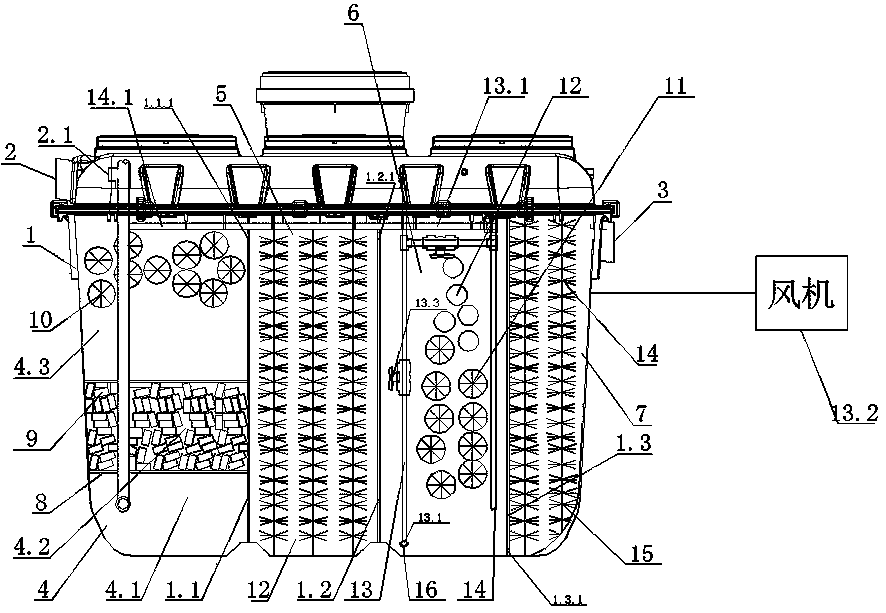

[0047] Example 2, such as figure 2 As shown, an MBBR-coupled ammonia oxidation integrated purification tank includes a horizontal shell 1, a water inlet 2 and a water outlet 3 respectively opened on the horizontal shell 1, and three pieces of the horizontal shell 1 are arranged. The main partition, the first partition 1.1, the second partition 1.2, and the third partition 1.3 divide the horizontal shell 1 into four sealed compartments, the first compartment 4 on the left is an anaerobic biological filter bed area, and the second compartment in the middle Compartment 5 is an anaerobic biofilm zone 1, the third compartment 6 in the middle is an MBBR zone, and the fourth compartment 7 on the right is an anaerobic biofilm zone 2, and a water inlet 2 is set near the top of the anaerobic biofilter bed zone, and the water inlet 2 is connected to the The water pipe 2.1 extends into the bottom end of the anaerobic biological filter bed area, and the anaerobic biofilm area 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com