Robot training platform

A training platform and robot technology, which is applied in the field of training systems, can solve the problems of lack of training systems and the inability to demonstrate different types of robots working together at the same time, and achieve the effects of improving safety and facilitating fixation and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

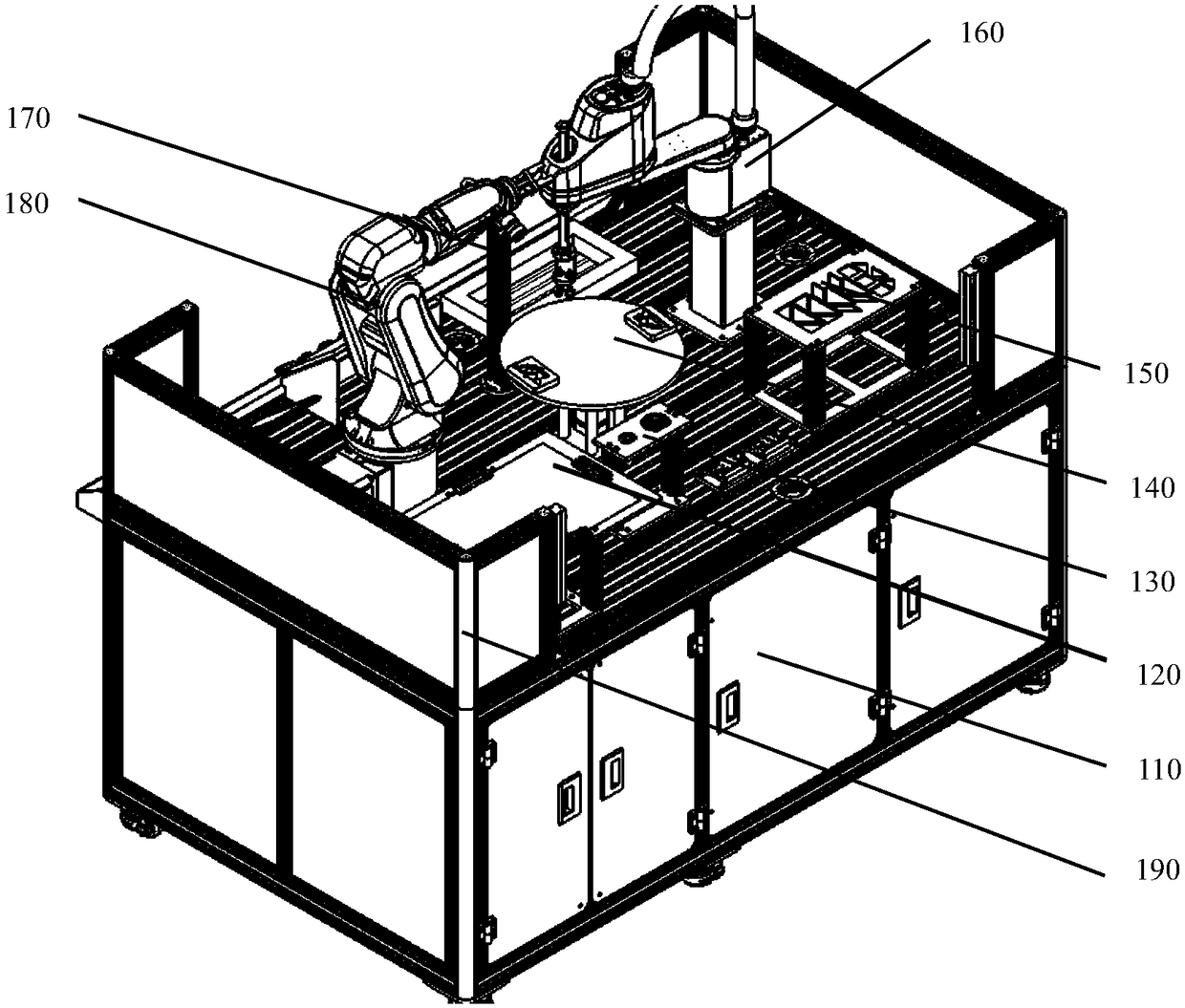

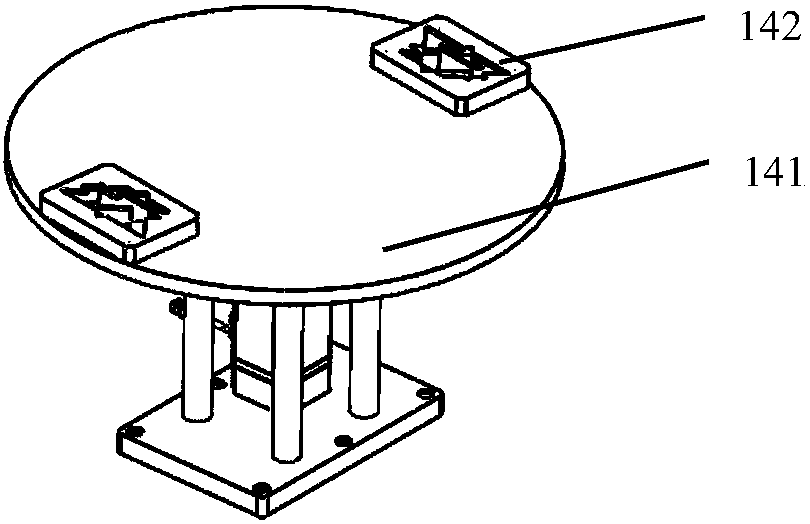

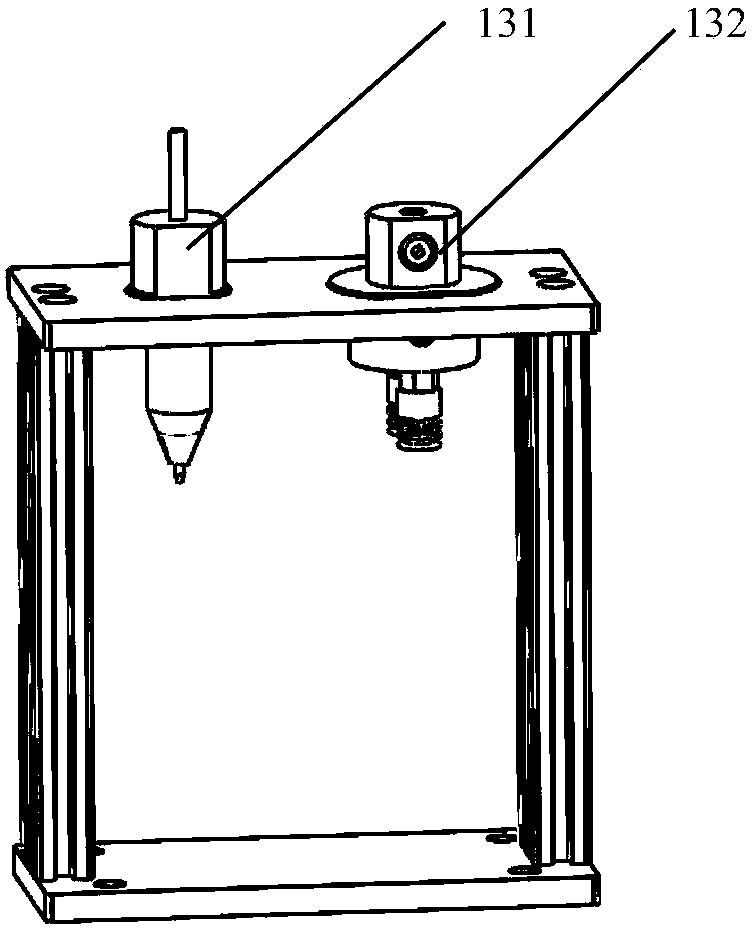

[0024] Such as Figure 1-Figure 3 As shown, this training platform demonstrates the functions of carrying jigsaw puzzles and reproducing the contours of jigsaw puzzles. Axis industrial robot 180, quick-change gripper warehouse 130, finished product placement table 120 and electrical control system, raw material warehouse 150, selective compliance assembly robot arm 160, assembly transfer mechanism 140, visual recognition mechanism 170, six-axis industrial robot 180, fast The hand changing warehouse 130 and the finished product placement platform 120 are set on the profile training table 110, the electrical control system is set inside the profile training table 110, and the assembly transfer mechanism 140 is located on the optional compliance assembly robot arm 160 and the six-axis industrial robot 180 Among them, the visual recognition mechanism 170 is located on one side of the assembly transfer mechanism 140, and the compliant assembly robot arm 160 is used to carry materia...

Embodiment 2

[0033] Such as Figure 4-Figure 6As shown, this training platform demonstrates the assembly button. The training platform includes a profile training table 110, a raw material warehouse 150, a selection compliance assembly robot arm 160, an assembly transfer mechanism 140, a visual recognition mechanism 170, a six-axis industrial robot 180, Quick-change gripper warehouse 130, finished product placement table 120, electrical control system, raw material warehouse 150, optional compliance assembly robot arm 160, assembly transfer mechanism 140, visual recognition mechanism 170, six-axis industrial robot 180, quick-change gripper warehouse 130 And the finished product placement platform 120 is set on the profile training table 110, the electrical control system is set inside the profile training table 110, the assembly transfer mechanism 140 is located between the selective compliance assembly robot arm 160 and the six-axis industrial robot 180, and the visual recognition The mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com