Beveling feed adjusting mechanism

An adjustment mechanism and material feeding technology, which can be used in thin material processing, metal processing, winding strips, etc., can solve problems such as poor feeding, excessive waste, and low efficiency, and achieve smooth feeding and prevent material jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

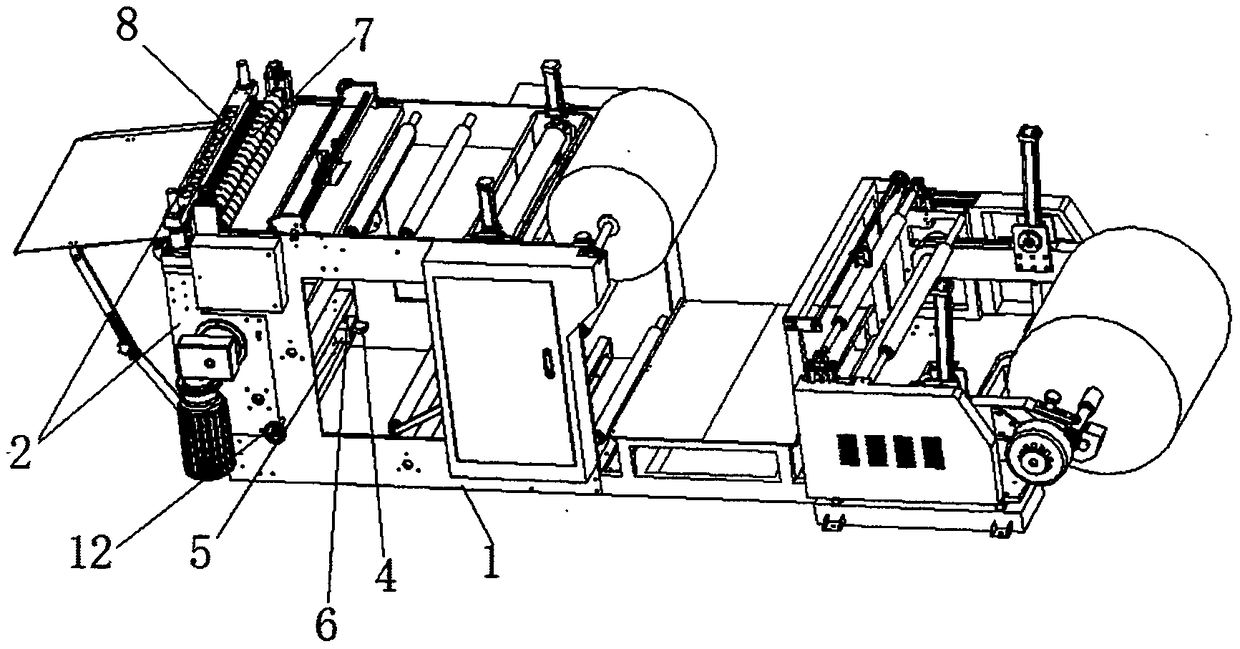

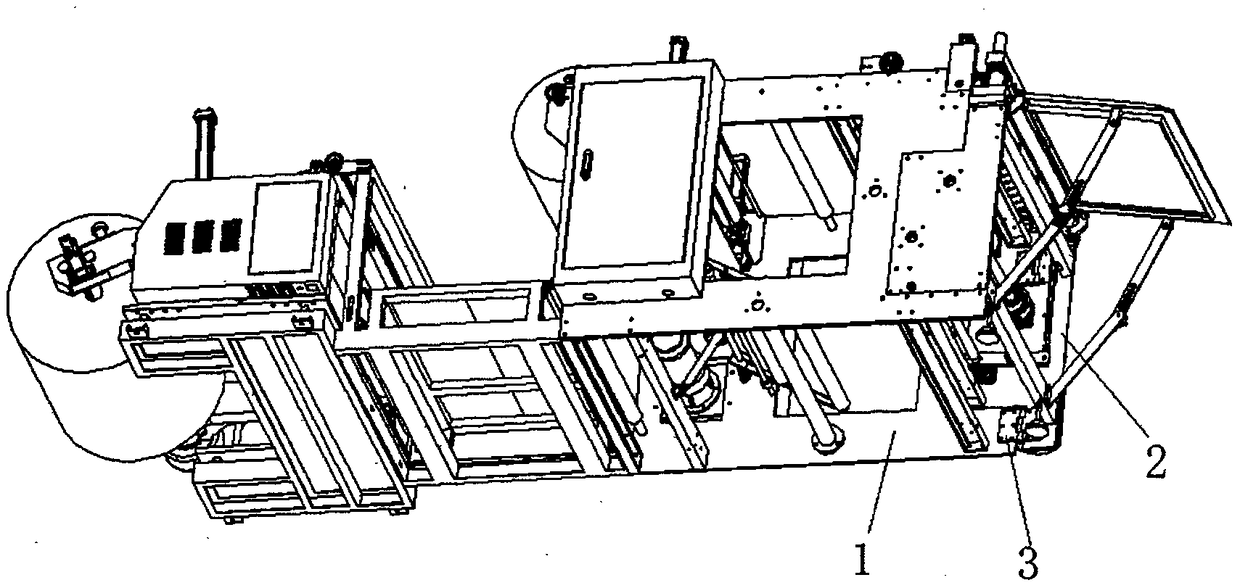

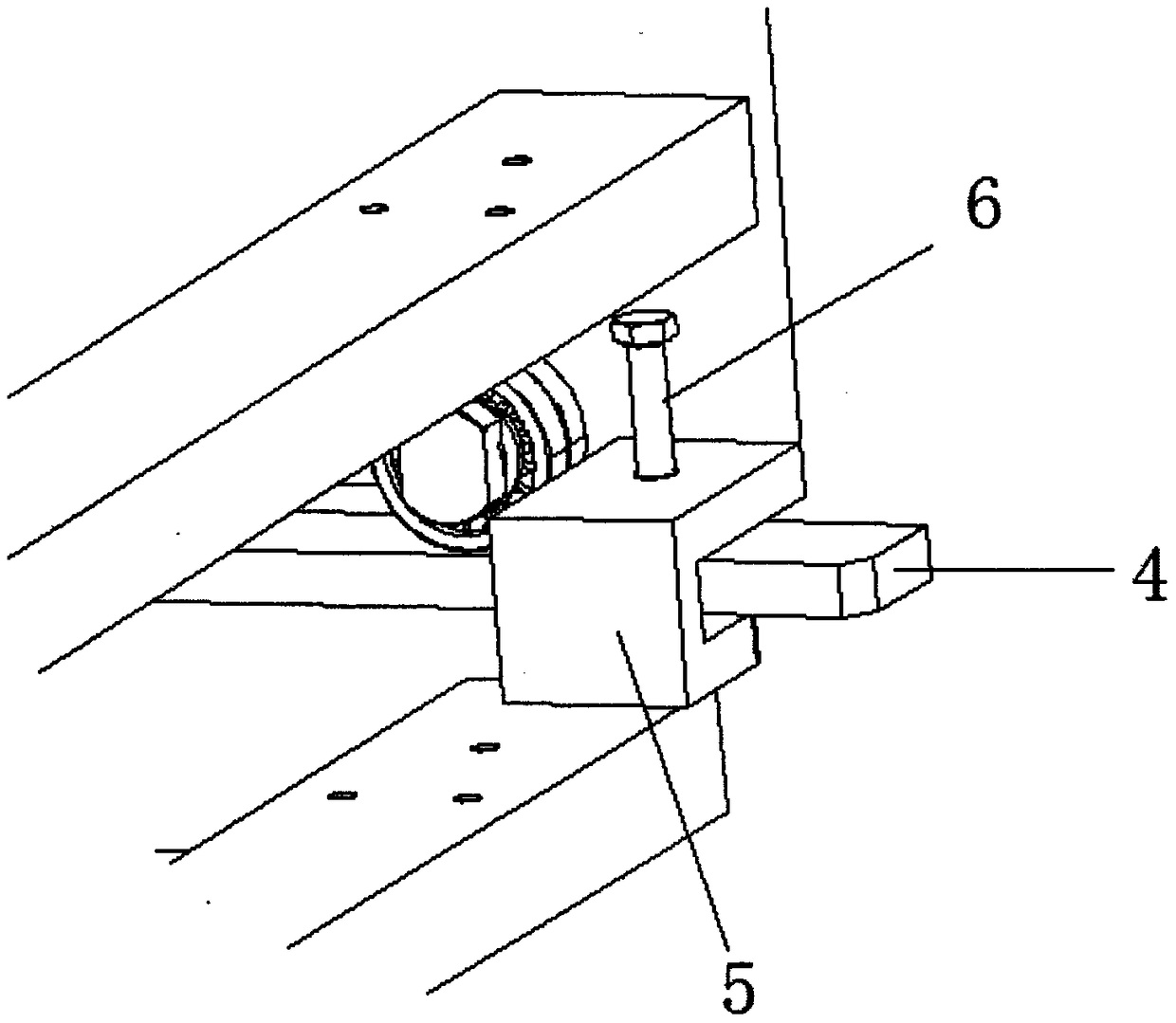

[0015] Such as figure 1 As shown, according to the embodiment of the present invention, the bevel feed adjustment mechanism includes: frame 1, frame 1 is fixed with cutting knife rest 2, roller frame 8 and feeding roller 7 successively from left to right, and above-mentioned cutting knife rest 2 is fixed On the leftmost side of frame 1, fixed by hinge 3 (refer to figure 2 ,From figure 2 We can see that the folding leaf 3 is fixed on the inner bottom side of the frame 1 and the folding knife rest 2), so that the cutting knife rest 2 can change at a certain angle along one direction, combined with image 3 Explain that the above-mentioned roller frame 8 is fixed on the top of the right side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com