Novel on-line defoaming perfusion equipment

A new type of defoaming technology, which is applied in the field of new online defoaming and perfusion equipment, can solve the problems of reducing the defoaming effect, occupying the factory building, increasing storage devices, etc., and achieves the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

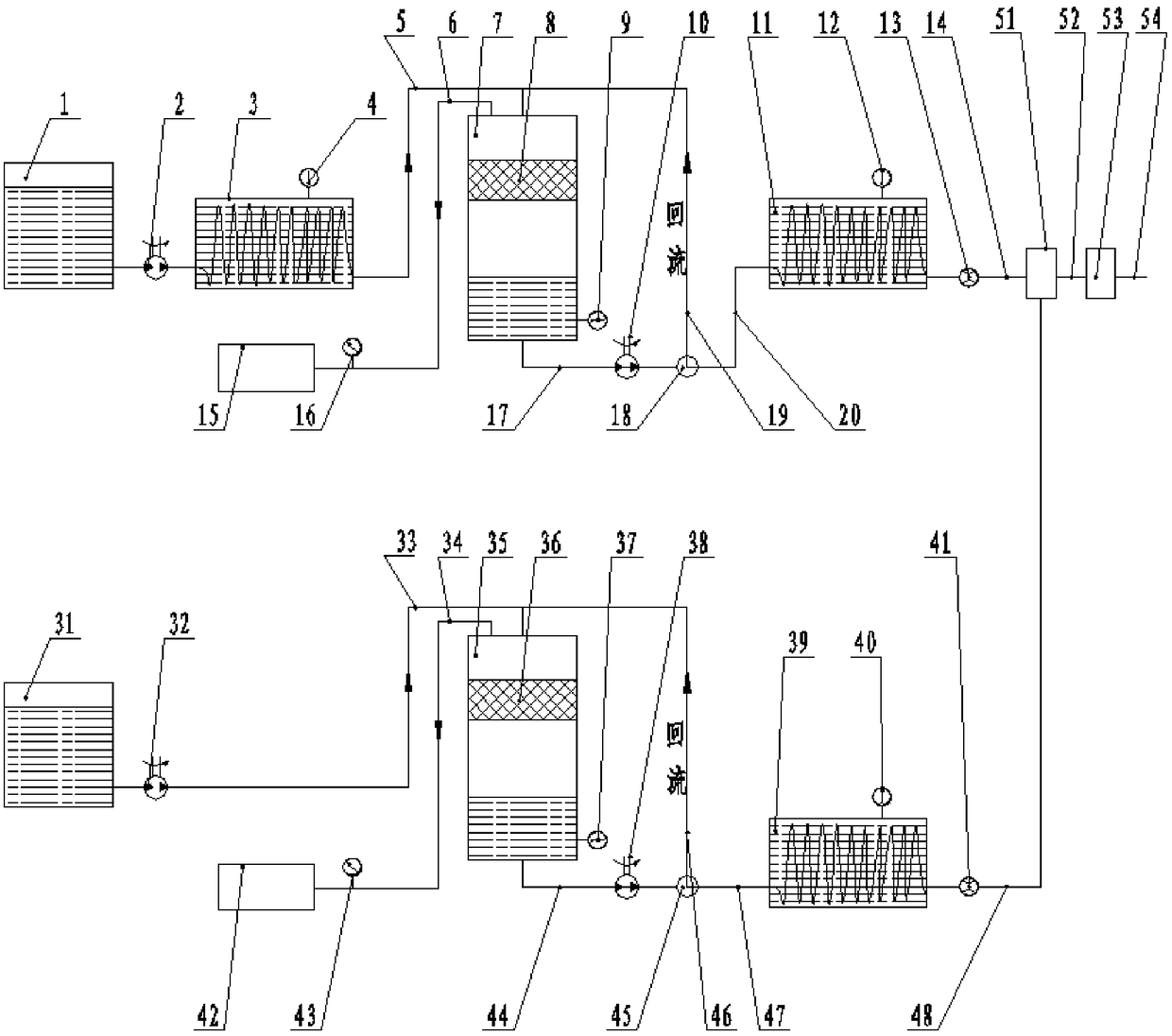

[0023] see figure 1 , a new type of on-line defoaming and filling equipment shown in the figure, including a defoaming cooling device for material A and a defoaming cooling device for material B, a mixing unit 51, and a buffer device 53.

[0024] The defoaming and cooling device for material A includes a rubber barrel 1, a feeding pump 2, a heating device 3, a vacuum filter tank 7, a delivery pump 10, and a cooling device 11; A temperature sensor 4 is installed on the device 3 . The outlet of the heating device 3 is connected to the feed port on the top of the vacuum filter tank 7 through the pipeline 5, and the vacuum port on the top of the vacuum filter tank 7 is connected to the vacuum pump 15 through the pipeline 6, between the vacuum pump 15 and the vacuum pump port of the vacuum filter tank 7 A pressure gauge 16 is installed on the pipeline 6.

[0025] The discharge port at the bottom of the vacuum filter tank 7 is connected to the first port of a three-way air control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com