Differential multi-shaft cascade electromechanical coupling device for hybrid electric vehicles

A technology of hybrid electric vehicles and electromechanical coupling, which is applied to the arrangement of multiple prime movers of power plants, pneumatic power plants, and general power plants, and can solve the problems of difficult integration, low efficiency, and slow development of hybrid electric vehicles. and other problems, to meet the high-speed demand, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

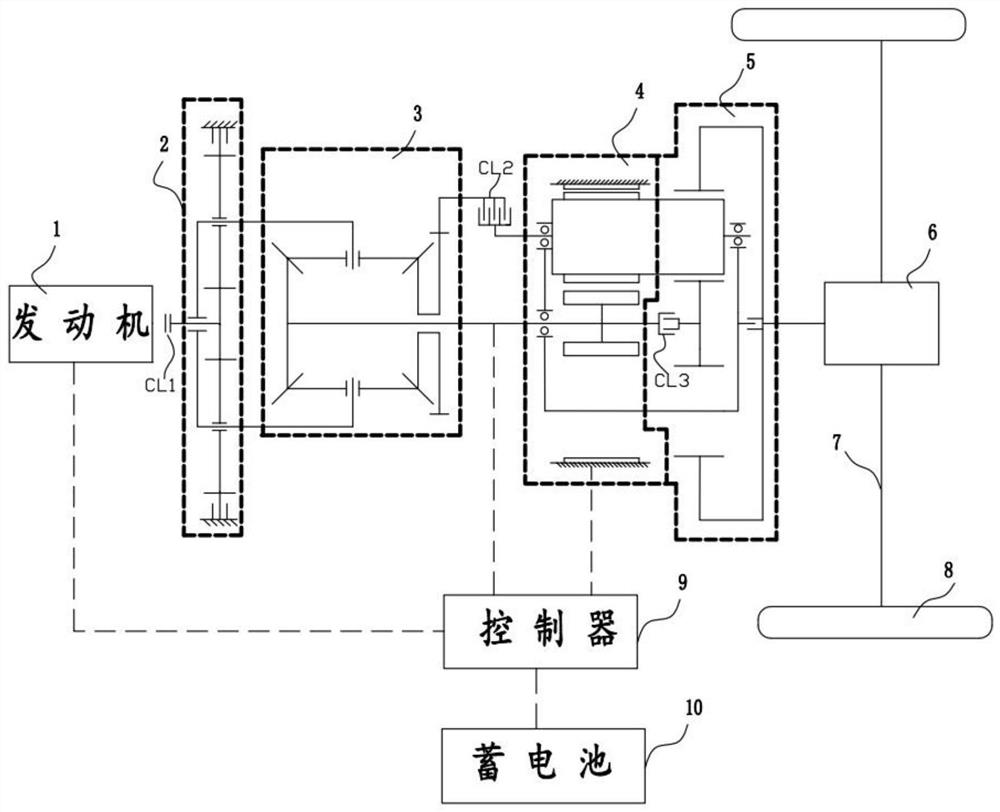

[0019] See figure 1 , The mechanism diagram of the differential multi-shaft-stage online electrical coupling device includes engine 1, first-stage planetary row 2, two-stage differential bevel gear planetary row 3, multi-shaft double-rotor motor 4, three-stage planetary row 5, differential Speed gear 6, three control components CL1, CL2, CL3, half shaft 7, wheels 8, engine and dual-rotor motor integrated controller 9, and battery 10.

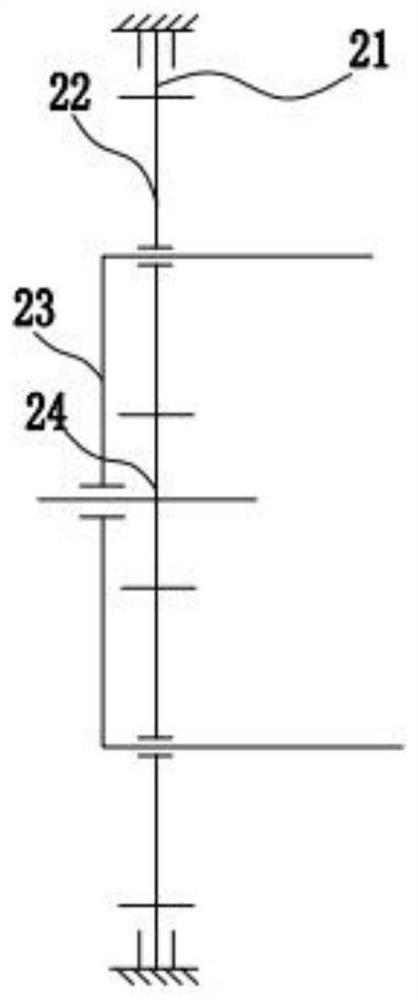

[0020] See figure 2 The first-stage planetary row includes a first-stage planetary row gear ring 21, a first-stage planetary row planetary gear 22, a first-stage planetary row planet carrier 23, and a first-stage planetary row sun gear 24. The engine power is transmitted through the first-stage planetary row sun gear 24 through the first-stage planetary row planetary gear 23. Since the first-stage planetary row planet carrier 22 is only connected with the second-stage differential bevel gear planetary gear 31, the gear ring 21 is restricted. Deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com