Method for removing arsenic from metallurgical off-gas spraying solution through multi-stage serial adsorption

A technology for smelting flue gas and spray liquid, applied in chemical instruments and methods, water/sewage multi-stage treatment, gaseous discharge wastewater treatment, etc., can solve problems such as weak adaptability, high material requirements, obvious advantages and disadvantages, etc. , to achieve a wide range of applications, low equipment requirements, and improve the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

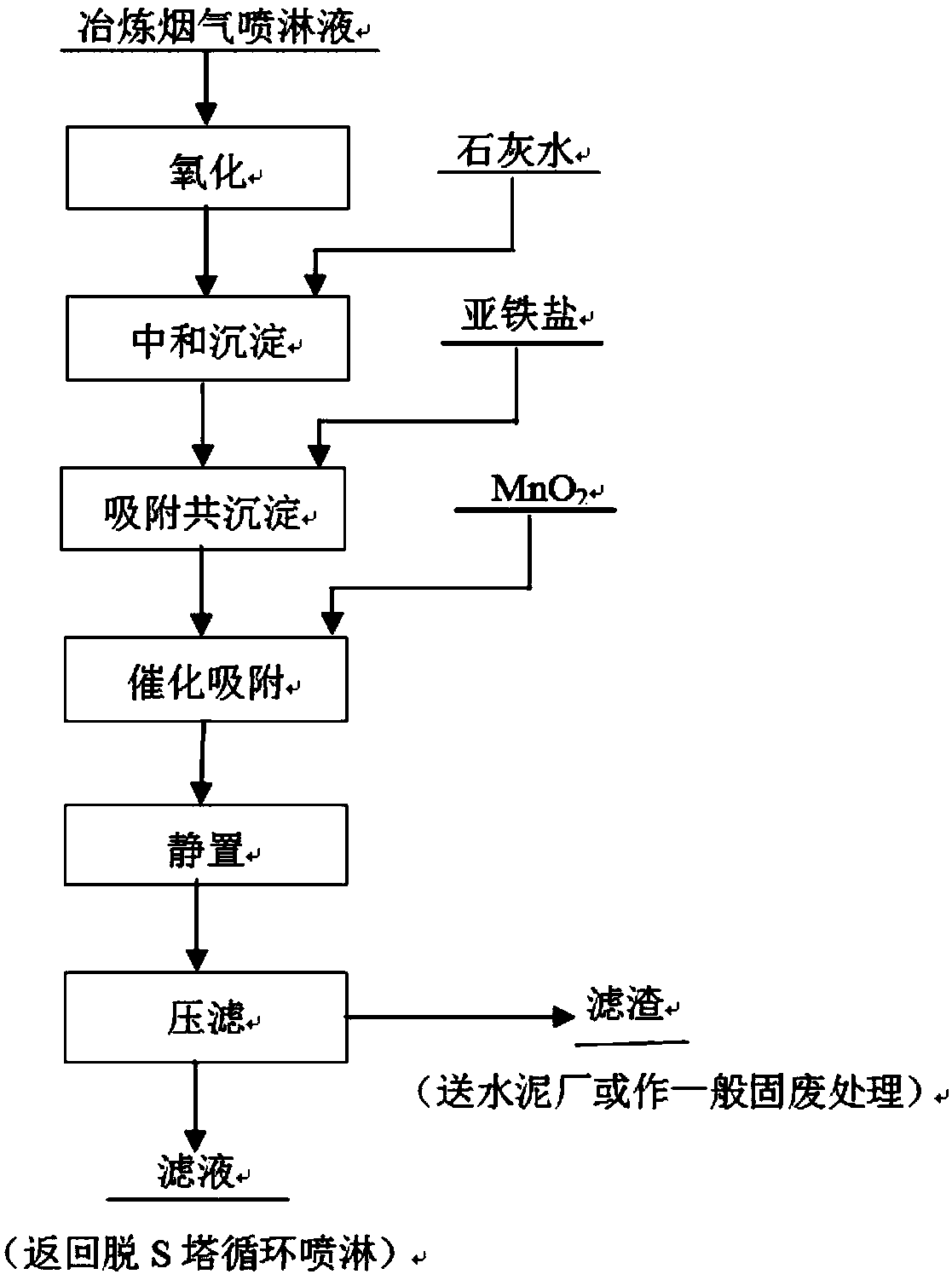

[0037] A method for removing arsenic by multi-stage series adsorption of smelting flue gas spray liquid, comprising the following steps:

[0038] (1) Oxidation: At normal temperature, air is blown into the spray liquid circulation tank, and the stirring speed is 400r / min under the mixer for 30min to obtain material 1;

[0039] (2) Neutralization reaction: lime water is pumped into material 1, and the end point of the reaction is that the pH of the material in the circulating tank is 6.5, and the reaction is stopped to obtain material 2;

[0040] (3) Adsorption-precipitation reaction: Add ferrous salt to material 2, and the reaction time is 30min, so that the mass ratio of Fe / As(Ⅲ,Ⅴ) is 0.85 to obtain material 3, wherein FeSO in ferrous salt 4 ·7H 2 The content of O is 85%, the form is loose, and the color is sky blue;

[0041] (4) Catalytic adsorption: the MnO 2 The powder was added to material 3, and the reaction time was 30 minutes, so that the mass ratio of Mn / As(Ⅲ,Ⅴ) wa...

Embodiment 2

[0044] A method for removing arsenic by multi-stage series adsorption of smelting flue gas spray liquid, comprising the following steps:

[0045] (1) Oxidation: At normal temperature, air is blown into the spray liquid circulation tank, and the stirring speed is 800r / min under the mixer for 60min to obtain material 1;

[0046] (2) Neutralization reaction: lime water is pumped into material 1, and the end point of the reaction is that the material pH in the circulating tank is 7, and the reaction is stopped to obtain material 2;

[0047] (3) Adsorption-precipitation reaction: Add ferrous salt to material 2, and the reaction time is 45min, so that the mass ratio of Fe / As(Ⅲ,Ⅴ) is 0.9 to obtain material 3, wherein FeSO in ferrous salt 4 ·7H 2 The content of O is 87%, the form is loose, and the color is sky blue;

[0048] (4) Catalytic adsorption: the MnO 2The powder was added to material 3, and the reaction time was 45 minutes, so that the mass ratio of Mn / As(Ⅲ,Ⅴ) was 0.35, and...

Embodiment 3

[0051] A method for removing arsenic by multi-stage series adsorption of smelting flue gas spray liquid, comprising the following steps:

[0052] (1) Oxidation: at normal temperature, blow air into the spray liquid circulation tank, and stir for 90 minutes under a mixer with a rotating speed of 1200r / min to obtain material 1;

[0053] (2) Neutralization reaction: lime water is pumped into material 1, and the end point of the reaction is that the material pH in the circulating tank is 7.5, and the reaction is stopped to obtain material 2;

[0054] (3) Adsorption-precipitation reaction: Add ferrous salt to material 2, and the reaction time is 60min, so that the mass ratio of Fe / As(Ⅲ,Ⅴ) is 1.0 to obtain material 3, wherein FeSO in ferrous salt 4 ·7H 2 The content of O is 89%, the form is loose, and the color is sky blue;

[0055] (4) Catalytic adsorption: the MnO 2 The powder was added to material 3, and the reaction time was 60 minutes, so that the mass ratio of Mn / As(Ⅲ,Ⅴ) wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com