Liquid lifting pipe for molten aluminum and preparation method thereof

A technology of liquid riser and molten aluminum, applied in the field of liquid riser for molten aluminum and its preparation, can solve the problems of low mechanical strength, no filtering equipment, and service life of sticky aluminum liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

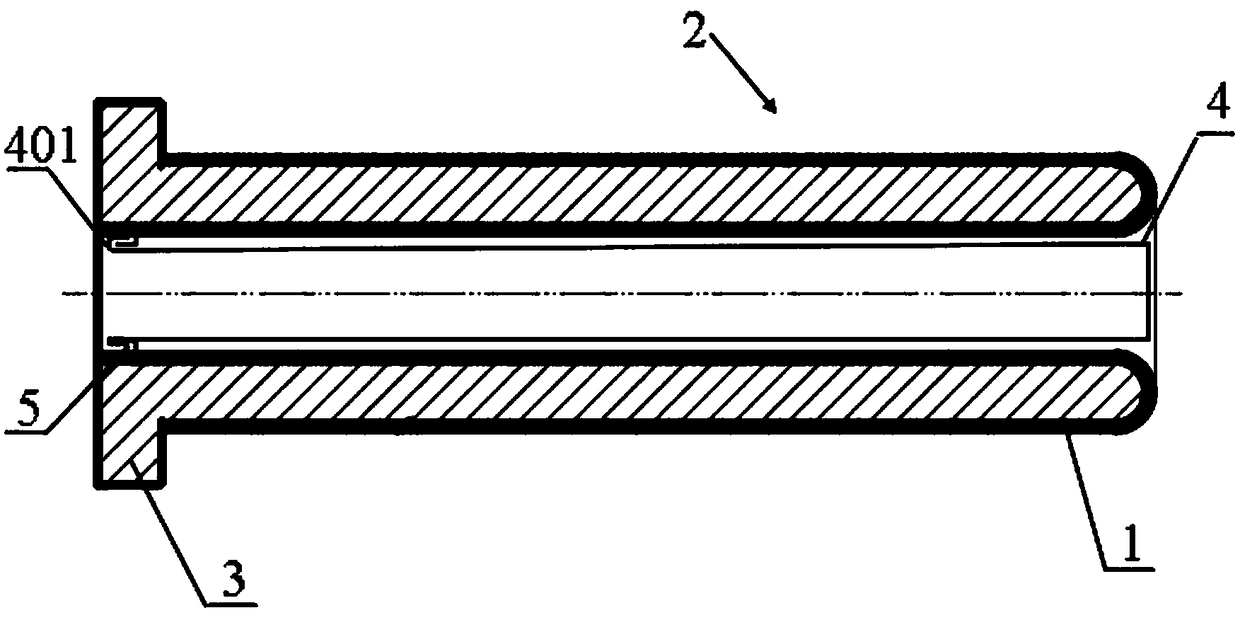

[0044] Such as figure 1 The shown riser pipe for aluminum liquid includes a cast iron pipe body 2 and a flange 3, one end of the cast iron pipe body 2 is provided with a flange 3, and the flange 3 is integrally formed with the cast iron pipe body 2; A cast iron flange 3 is added to the upper connection of the riser pipe, and the damage to the riser pipe is avoided when the mold is connected with the riser pipe bolt; the inside of the riser pipe is provided with a filter bag 4, and the front end of the filter bag 4 is provided Snap 401, the design of the filter bag 4 can play a good role in skimming, and at the same time can ensure that the aluminum liquid flows smoothly into the mold, and the filter bag 4 is placed in the liquid riser in a detachable form, which is convenient Cleaning; the inner wall of the flange 3 is provided with an annular groove 5 corresponding to the engagement 401, and the outer periphery of the flange 3 is provided with bolt holes; the inner wall of th...

Embodiment 2

[0049] A riser pipe for liquid aluminum comprises a cast iron pipe body, the inner and outer walls of the cast iron pipe are enamelled with an enamel layer resistant to corrosion by molten aluminum; the mass component of the enamel layer in the enamel layer contains SiO 2 : 40%, B 2 o 3 : 8%, Na 2 O: 13%, Al 2 o 3 : 23.9%, TiO 2 : 6%, CaO: 2%, K 2 O: 1%, CoO: 0.1%, NiO: 3%, Fe 2 o 3 : 3%.

[0050] The preparation method of described liquid riser comprises:

[0051] (1) prepare cast iron pipe body;

[0052] (2) Surface treatment of cast iron pipe body: cleaning, shot blasting and shot blasting are performed on the inner and outer surfaces of cast iron pipe in sequence;

[0053] (3) Preparation of enamel glaze: the formula of enamel glaze in terms of mass percentage is: SiO 2 : 40%, B 2 o 3 : 8%, Na 2 O: 13%, Al 2 o 3 : 23.9%, TiO 2 : 6%, CaO: 2%, K 2 O: 1%, CoO: 0.1 parts%, NiO: 3%, Fe 2 o 3 : 3%, the enamel glaze is powdery after preparation, add a certain ...

Embodiment 3

[0057] A liquid riser for aluminum liquid, characterized in that the liquid riser comprises a cast iron pipe body, and the inner and outer walls of the cast iron pipe are enamelled with an enamel layer resistant to corrosion by aluminum liquid; the enamel layer Medium enamel quality component contains SiO 2 : 41%, B 2 o 3 : 18%, Na 2 O: 13%, Al 2 o 3 : 13.3%, TiO 2 : 4.5%, CaO: 3%, K 2 O: 3%, CoO: 0.2%, NiO: 2%, Fe 2 o 3 :2%.

[0058] The preparation method of described liquid riser comprises:

[0059] (1) prepare cast iron pipe body;

[0060] (2) Surface treatment of cast iron pipe body: cleaning, shot blasting and shot blasting are performed on the inner and outer surfaces of cast iron pipe in sequence;

[0061] (3) Preparation of enamel glaze: the formula of enamel glaze in terms of mass percentage is: SiO 2 : 41%, B 2 o 3 : 18%, Na 2 O: 13%, Al 2 o 3 : 13.3%, TiO 2 : 4.5%, CaO: 3%, K 2 O: 3%, CoO: 0.2%, NiO: 2%, Fe 2 o 3 : 2%, the enamel glaze is powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com