Patents

Literature

36results about How to "Not easy to break and crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of machine-made charcoal

InactiveCN105349212AWide choiceLow cost of preparationBiofuelsSolid fuelsComposite materialCombustion

The invention provides a production method of machine-made charcoal and relates to the technical field of charcoal processing. The machine-made charcoal is prepared from 90 parts by weight of sawdust, 15 parts by weight of bamboo powder, 20 parts by weight of levant cotton exocarp powder, 15 parts by weight of peanut shell powder, 20 parts by weight of corn straw powder, 25 parts by weight of Artemisia argyi powder, and 6 parts by weight of diatomite. The sawdust, bamboo powder, levant cotton exocarp powder, peanut shell powder, corn straw powder and Artemisia argyi powder have particle diameters of 0.5-0.8mm and are obtained by drying, crushing, centrifugation screening and rough impurity removal. The production method has a wide raw material selection range, a low preparation cost and simple and easy processes. The machine-made charcoal has good density and long combustion time, contains diatomite for improving raw material viscosity, can be molded easily, does not easily crack and has high product quality.

Owner:和县伊迈炭业有限责任公司

Artificial stone for raised pieces and preparation method of artificial stone for raised pieces

The invention discloses an artificial stone for raised pieces. The artificial stone comprises the followingcomponents: 80-120 parts of unsaturated polyester resin, 120-400 parts of calcium carbonate or aluminium hydroxide, 10-30 parts of perlite, 0-3 parts of active carbon, 0-3 parts of radiation protection lead powder, 1-5 parts of polyester fibre or glass fibre, 1-3 parts of accelerator, and 0.5-2 parts of a curing agent. The invention discloses a preparation method of the artificial stone for the raised pieces, and the preparation method comprises the following steps: mixing the materials proportionally and blending uniformly; heating the mixture to be 30-50 DEG C; adding the heated mixture into a mould with skeletons; vibrating; vacuuming; curing; and demoulding. Compared with the raised pieces made of other natural stone materials or other artificial stones, the raised pieces made of the artificial stone provided by the invention are lighter, and have higher hardness (Barcol hardness more than or equal to 55), better toughness (impact toughness more than or equal to 3.5kJ / sq.m<2>), stronger shock resistance (flexural strength more than or equal to 40MPa). Compared with other raised pieces, the raised pieces made of the artificial stone provided by the invention have the characteristics of firmness, durability, twist resistance, and unlikeness to deform, crack and break.

Owner:FUYANG XINMEIJU SPECIAL ARTS CARVING

Ceramic vessel capable of activating water molecules and preparation method of ceramic vessel

InactiveCN104987040AImprove solubilityImprove cleanlinessWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by sorptionSolubilityHazardous substance

The invention discloses a ceramic vessel capable of activating water molecules and a preparation method of the ceramic vessel. The ceramic vessel is composed of, by weight, 17-29 parts of Sibin floating stone, 14-26 parts of hematite, 10-15 parts of crystal broken stone, 5-10 parts of chalcedony, 16-28 parts of Muyu stone, 12-24 parts of six-ring stone, 10-15 parts of Shuiyuan stone, 8-16 parts of glauconite, 4-8 parts of pearl powder, 3-6 parts of yeast powder, 5-10 parts of deep sea mineral salt, 4-7 parts of alums and 3-5 parts of antimicrobial powder. The prepared ceramic vessel can release anions, far infrared rays and magnetic fields, can make water molecules resonant, activate water molecules, change large-molecular-group water into small-molecular-group water and improve the dissolving capacity, cleaning power and seepage force of water, and can also kill bacteria in water, decompose harmful substances in water, adsorb peculiar smell in water, enhance gap values of water molecules, improve the activating effect, solubility and wettability of water, reduce the adhesive effect in water and soften hard water.

Owner:安徽省德邦瓷业有限公司

Health-type charcoal for indoor warming

The invention provides health-type charcoal for indoor warming, and relates to the technical field of charcoal processing. The health-type charcoal is produced from the following components in parts by weight: 65 parts of saw dust, 25 parts of bamboo leaf, 8 parts of folium mori, 12 parts of peanut shell, 25 parts of pomegranate bark, 15 parts of selfheal, 25 parts of wormwood, 12 parts of plantain, 6 parts of poria cocos, 8 parts of wild jujube twig, 5 parts of lotus seedpod, 9 parts of calamus and 35 parts of diatomite. The produced charcoal is used for indoor warming, and fresh aroma is generated through charcoal combustion; hot smoke generated in combustion can be used for treating neurasthenia, with the symptoms of insomnia and dreaminess, palpitation and the like, caused by insufficiency of heart yin; the health-type charcoal has the efficacies of quieting heart and calming nerves.

Owner:和县伊迈炭业有限责任公司

High strength lathe tool blade machining technology

InactiveCN108942128AHigh surface hardnessLow core hardnessFurnace typesIncreasing energy efficiencyEdge strengthHigh intensity

The invention discloses a high strength lathe tool blade machining technology. A lathe tool blade manufactured through the technology is high in surface hardness, the hardness of a core part is low, while the external cutting edge strength is guaranteed, the good toughness is achieved, breaking and cracking are not prone to occurrence, the cutting edge is not prone to being damaged, and the service life is long.

Owner:江苏扬碟钻石工具有限公司

Soft embedding section specimen and production method thereof

ActiveCN109523873AEasy to storeEasy to useDead animal preservationEducational modelsResin embeddingPre treatment

The invention relates to a soft embedding section specimen and a production method thereof, and belongs to the technical field of biological resin embedding section. The method comprises the steps that a biological specimen is frozen and sawed into slice section specimens, and pre-processed section specimens are obtained after dehydrating and defatting are conducted on the section specimens; the pre-processed section specimens are embedded in molds, a soft embedding agent fills the molds under a non-inducing temperature, wherein the embedding agent is an embedding agent which has flexibility after curing; curing is conducted at the inducing temperature after filling is completed, and the producing is completed. The specimen has the advantages that the flexibility after curing is better, cracking and deforming do not easily take place, and the storage and use are convenient.

Owner:河南中博科技有限公司

Bonded type coating board for outer wall and manufacturing method thereof

InactiveCN104328885AThe overall thickness is thinReduce weightCovering/liningsCeramic shaping apparatusFiberglass meshGlass fiber

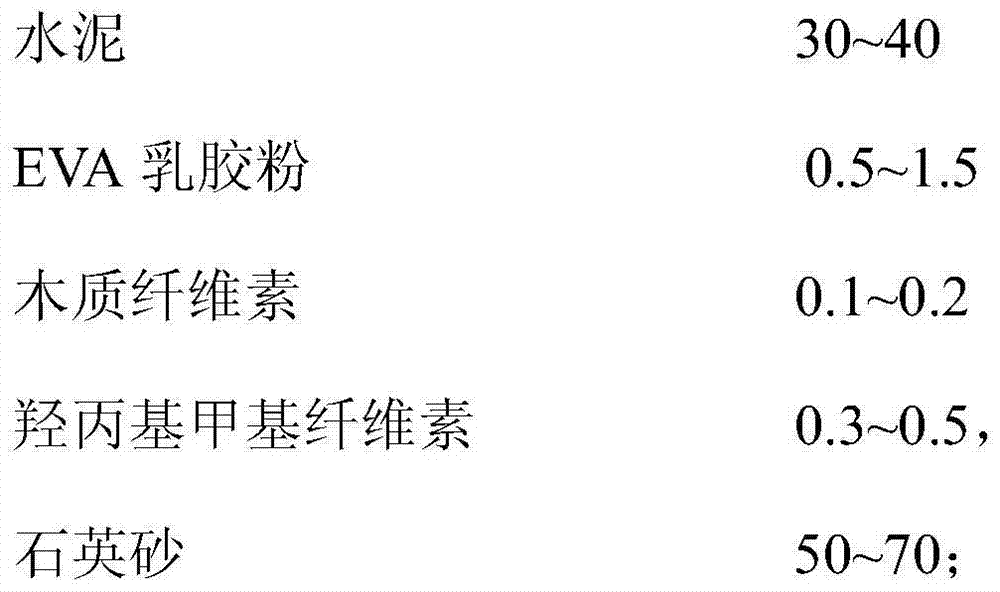

The invention relates to a bonded type coating board for an outer wall and a manufacturing method thereof. The invention aims at providing the coating board which is light and thin and can be directly bonded on the outer wall of a building for construction. The method has the characteristic of convenience in manufacture. The technical scheme is as follows: the bonded type coating board comprises a mold plate and a coating layer positioned on the surface of the mold plate. The bonded type coating board is characterized in that the mold plate consists of glass-fiber gridding cloth and a bonding material filling the glass-fiber gridding cloth. The bonding material comprises the following components in parts by weight: (1) component A: cement, EVA latex powder, lignocellulose and hydroxypropyl methyl cellulose; filling aggregate; (2) component B: acrylic acid waterproof emulsion. The manufacturing method is carried out by the following steps of (1) preparing materials; (2) manufacturing into the mold plate; (3) curing and drying; (4) coating the formed mold plate with primer; (5) coating coatings in coating; (6) spraying the coatings; (7) spraying finishing paint; and (8) cutting into blocks and laminating films for protection.

Owner:浙江华特实业集团华特化工有限公司

Liquid lifting pipe for molten aluminum and preparation method thereof

PendingCN108251865AExtended service lifeConsistent mechanical strengthUltimate tensile strengthCast iron pipe

The invention discloses a liquid lifting pipe for molten aluminum. The pipe comprises a cast iron pipe body and a flange, the flange is arranged at one end of the cast iron pipe body, and the flange and the cast iron pipe body are integrally formed; a filtering net bag is arranged inside the liquid lifting pipe, the front end of the filtering net bag is provided with a clamping part, an annular groove corresponding to the clamping part is formed in the inner wall of the flange, and the surface of the inner wall and the surface of the outer wall of the cast iron pipe body are coated with an enamel glaze layer resistant to corrosion of the molten aluminum in an enameling mode; the enamel glaze in the enamel glaze layer contains the components of, by mass, 40-55% of SiO2, 8-18% of B2O3, 13-18% of Na2O, 10-25% of Al2O3, 3-6% of TiO2, 2-4% of CaO, 1-3% of K2O, 0.1-0.3% of CoO, 1-3% of NiO and 1-3% of Fe2O3. The liquid lifting pipe combines the advantage of corrosion resistance of a ceramicliquid lifting pipe and the advantages of being high in mechanical strength and not prone to breakage of a cast iron liquid lifting pipe.

Owner:周志英

Modified bamboo fiber reinforced composite high-density polyethylene resin based flame-retardant cupboard board and preparation method thereof

The invention discloses a modified bamboo fiber reinforced composite high-density polyethylene resin based flame-retardant cupboard board. The bamboo-plastic board is prepared from, by weight, 50-60 parts of modified bamboo fibers, 20-25 parts of high-density polyethylene, 10-15 parts of polyvinyl chloride resin, 3-5 parts of maleic anhydride grafted styrene, 1-2 parts of halloysite nanotubes, 0.1-0.2 part of a silane coupling agent, 3-5 parts of glycidyl methacrylate, 5-6 parts of ionic liquid, 1-2 parts of hydrogenated castor oil, 0.1-0.2 part of an antioxidant and 1-1.5 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

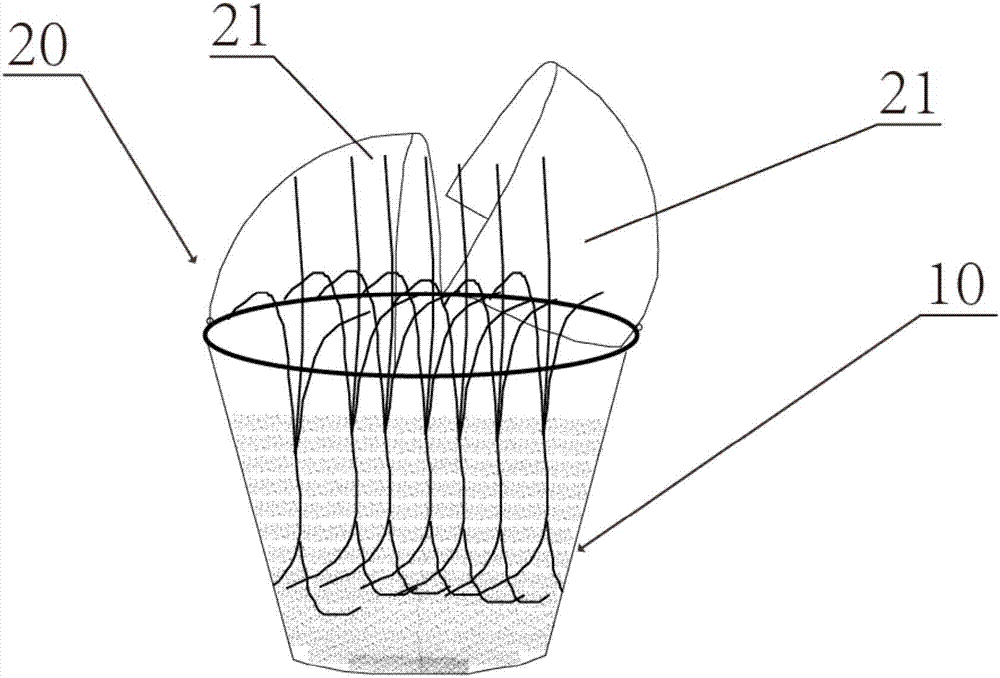

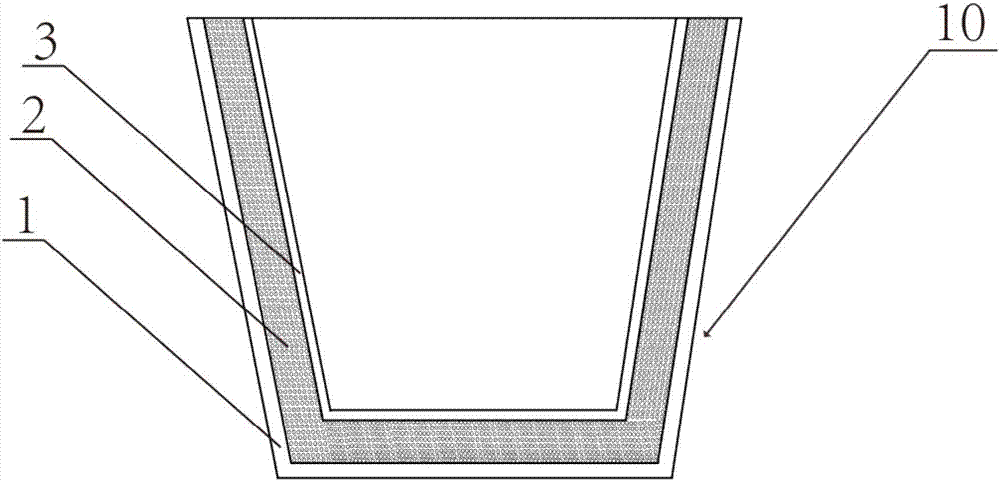

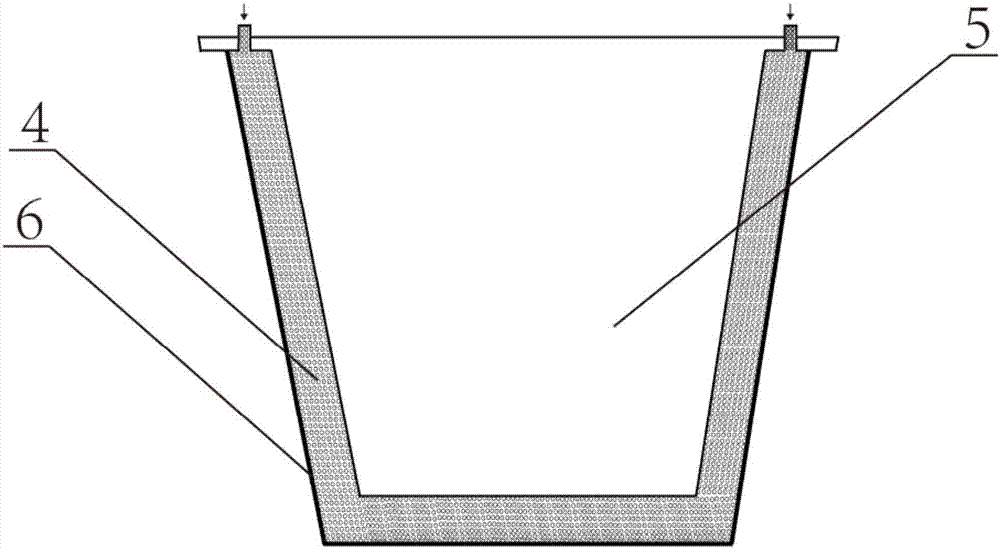

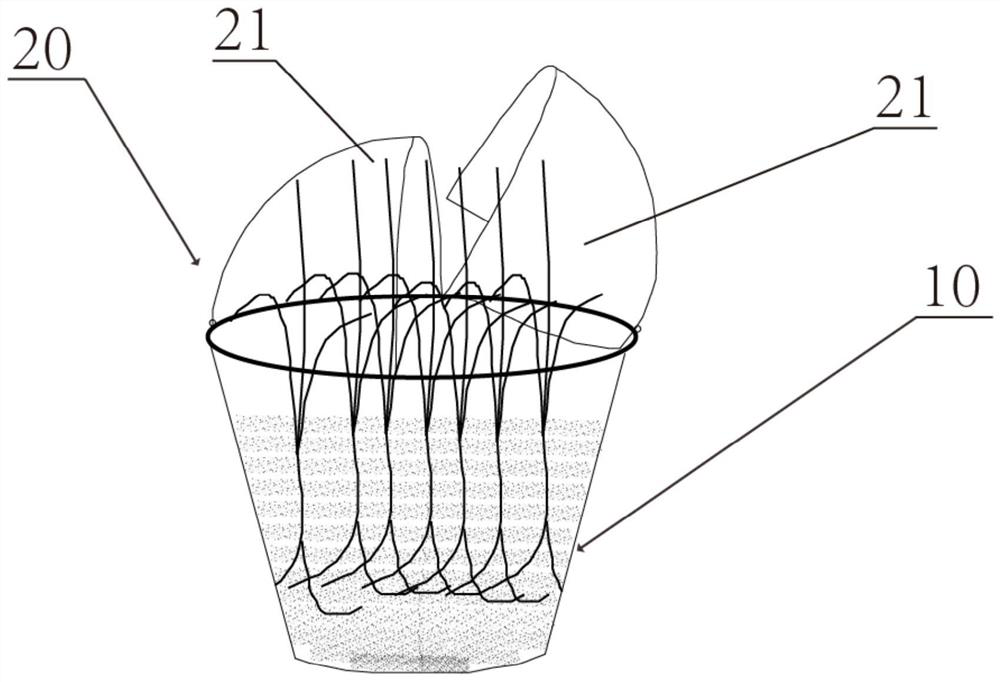

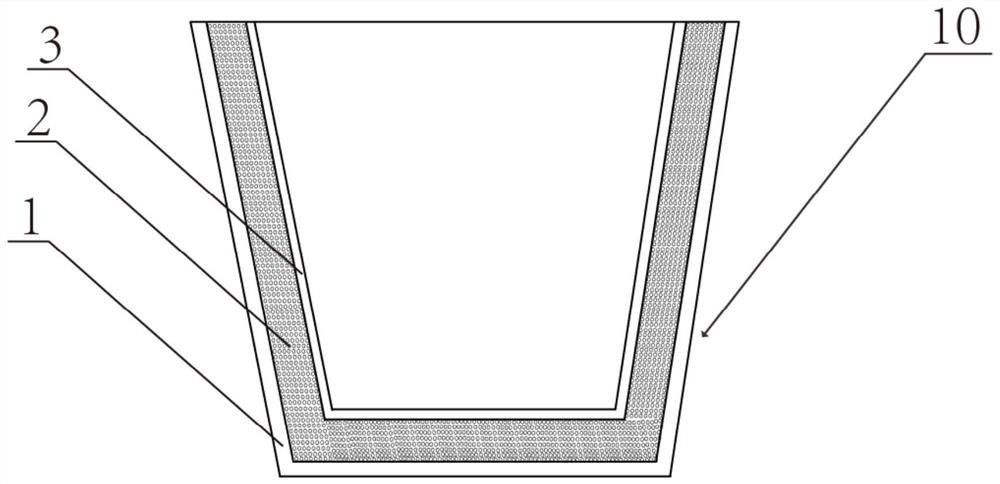

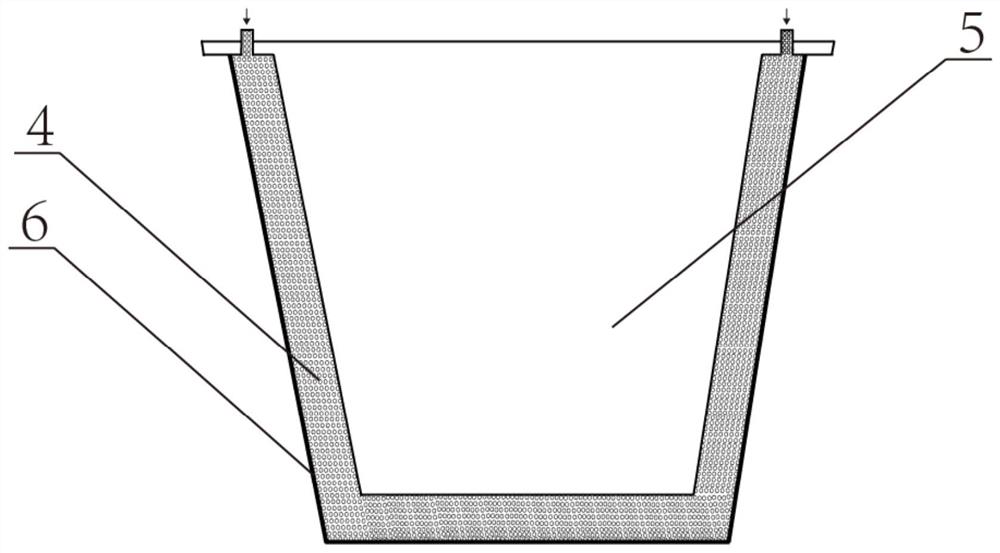

Thermal insulation flowerpot for planting plants and preparing method thereof

ActiveCN107371862ALight in massVarious shapesSynthetic resin layered productsDomestic containersThermal insulationExpanded clay aggregate

The invention discloses a thermal insulation flowerpot for planting plants. The flowerpot comprises a pot body for storing nutrient soil required for planting plants, a pot cover arranged on the upper edge of the pot body, and cover shells integrated with the pot cover and capable of being opened and closed. The two cover shells are connected with the upper edge of the pot body through hinges respectively. The pot body comprises an acrylic layer, a perlite mixed resin layer and an FRP fiber layer in sequence from outside to inside. Adhesive layers for preventing two layers from disengagement and separation are arranged between the acrylic layer and the perlite mixed resin layer and between the perlite mixed resin layer and the FRP fiber layer. The acrylic layer is 0.5-2.5 mm thick, the perlite mixed resin layer is 20-30 mm thick, and the FRP fiber layer is 0.5-2.5 mm thick. The flowerpot prepared with surface hole-closed expanded perlite earthenware as the thermal insulation material is light in weight and good in thermal insulation effect. Meanwhile, the invention further provides a preparing method for preparing the flowerpot from surface hole-closed expanded perlite earthenware.

Owner:广东盛达穗南环保科技有限公司

Medicinal mineral ceramic bowl and preparation method thereof

InactiveCN104926278AIncrease health functionHigh mechanical strengthPlatesClaywaresPhosphateCalcium formate

The invention discloses a medicinal mineral ceramic bowl and a preparation method thereof. The bowl is prepared from the following raw materials in parts by weight: 19-27 parts of vermiculite, 15-25 parts of calcite, 13-21 parts of yellow clay, 12-18 parts of noselite, 14-26 parts of gypsum rubrum, 16-28 parts of actinolite, 12-18 parts of ochre, 21-33 parts of argil, 10-15 parts of attapulgite, 7-13 parts of yellow dextrin, 4-6 parts of carboxymethyl glucan sodium, 3-5 parts of aluminium dihydrogen phosphate, 2.5-4.5 parts of calcium formate and 7-9 parts of antimicrobial powder. According to the invention, medicinal minerals like vermiculite, calcite, yellow clay, noselite, gypsum rubrum, actinolite and ochre are adopted and compounded to prepare the ceramic bowl, so that the ceramic bowl is relatively high in health care function; if often used for eating, the bowl can provide the efficacies of clearing heat, removing toxicity, relieving convulsion, soothing the nerves, being antibacterial, diminishing inflammation, tonifying the spleen, astringing intestine, cooling blood, diminishing swelling, and the like, and is beneficial for body health; moreover, the ceramic bowl prepared from the invention has the advantages of being high in mechanical strength, not easy to crack and break, and durable in use.

Owner:安徽省含山瓷业股份有限公司

Multifunctional protective well cover assembly

InactiveCN104695484AThere will be no jumping phenomenonClearly tameArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention discloses a multifunctional protective well cover assembly, which comprises a first caution cover and a second caution cover, wherein the first caution cover and the second caution cover are respectively hinged to the two sides of an inspection well, and oppositely arranged; a first connecting rod is arranged at the bottom of the first caution cover, and perpendicular to the plane of the first caution cover; a second connecting rod is arranged at the bottom of the second caution cover, and perpendicular to the plane of the second caution cover; a well seat is mounted on the inspection well; a well cover is arranged in the well seat, and connected with the well seat through a sliding connecting assembly; three transverse clamping nails and three L-shaped clamping grooves are respectively arranged at 45-degree inclined edges of the well cover and the well seat, and the clamping nails and the clamping grooves are mutually and correspondingly arranged. The multifunctional protective well cover assembly has the advantages that the structure is simple; an excellent caution and protection function for an inspection well lacking in the well cover can be achieved, so that the potential safety hazards can be reduced; the functions of preventing the well cover from being jacked up by rainwater, sounding, jumping, being pried, cracking, settling and dropping can integrate.

Owner:武克勇

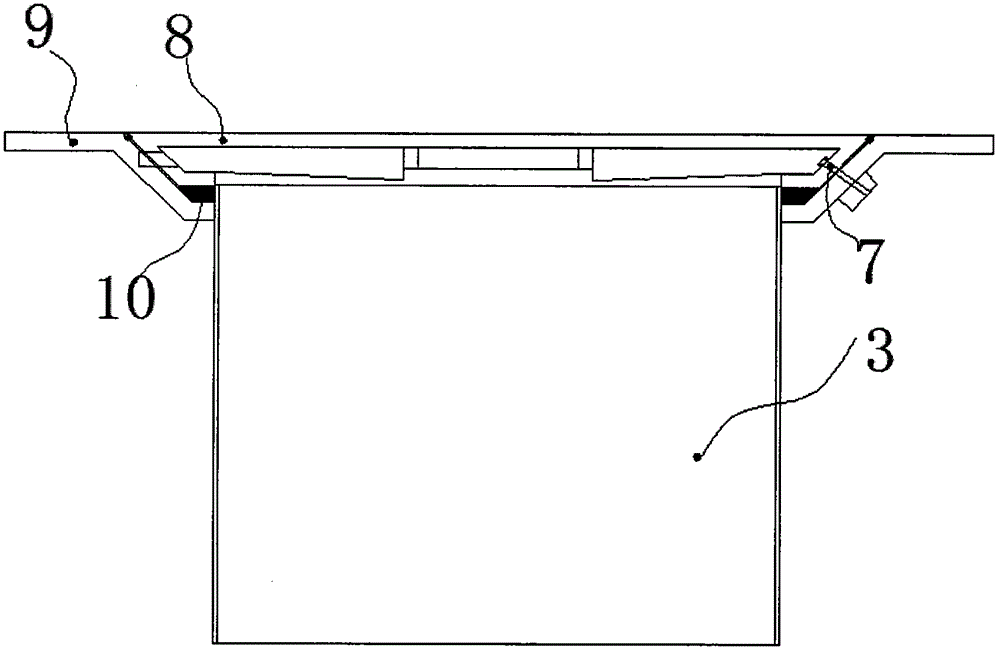

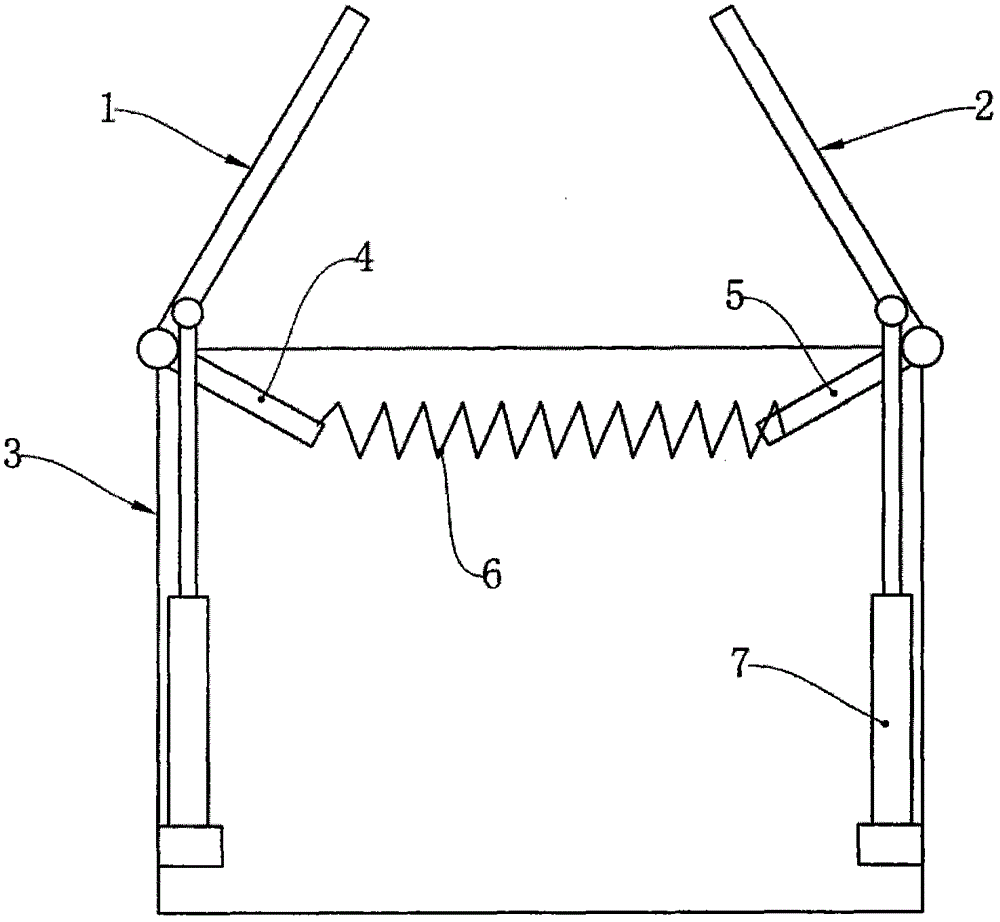

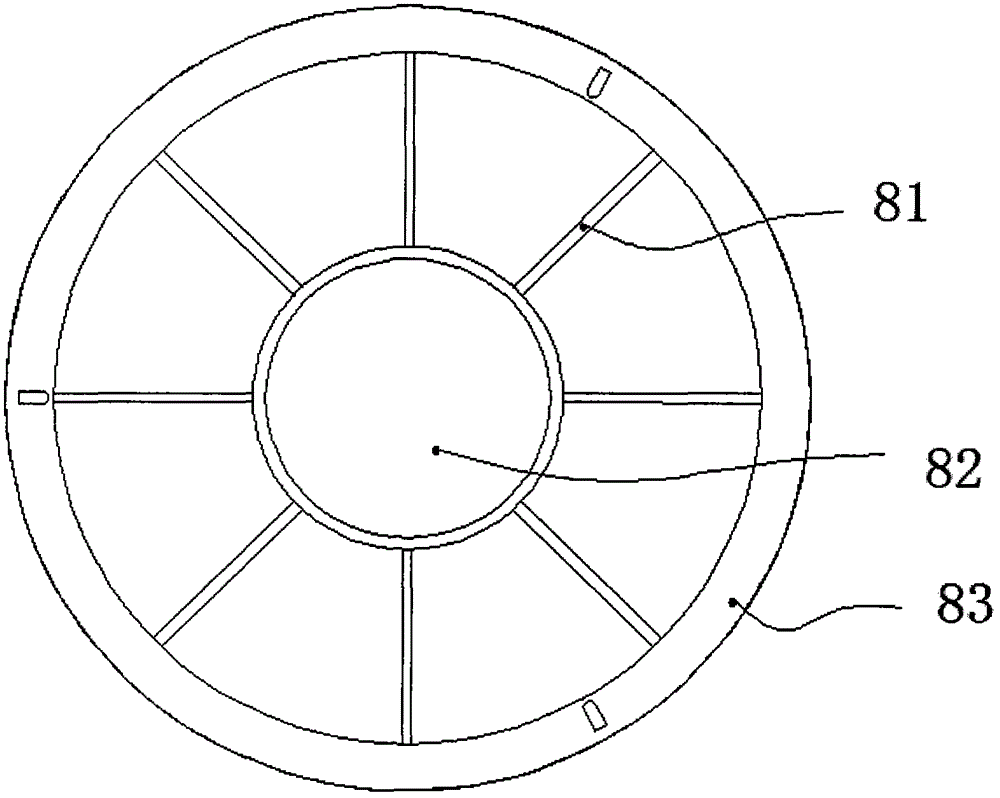

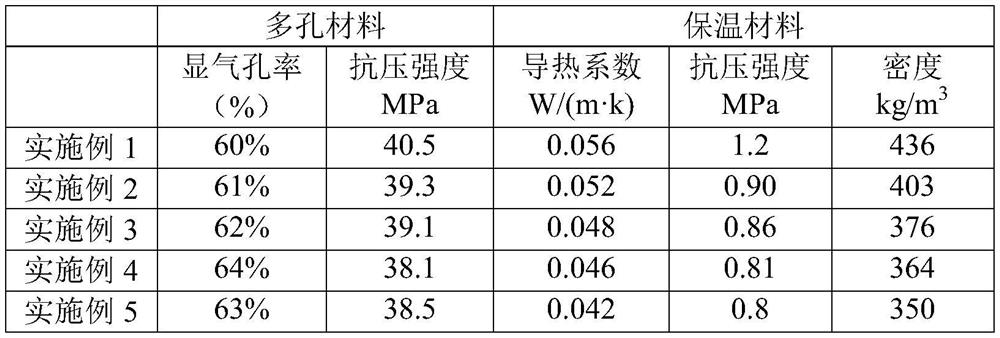

Hydraulic engineering thermal insulation material and preparation method thereof

ActiveCN113666770AReduce dry lines and other problemsImprove insulation effectCeramicwareAluminium chlorideFoaming agent

The invention discloses a hydraulic engineering thermal insulation material, and relates to the technical field of thermal insulation material production. The hydraulic engineering thermal insulation material is prepared from the following raw materials by weight: 20-30 parts of slag cement, 5-10 parts of mica powder, 5-10 parts of a porous material, 2-3 parts of glass micro-beads, 0.6-1 part of a foaming agent, 1-2 parts of polyaluminum chloride, 1-2 parts of potassium polyacrylate, and 18-25 parts of water. According to the invention, the porous material prepared from the waste ceramic and the plant fibers is added into the thermal insulation material, so that the thermal insulation material is good in thermal insulation performance, high in strength, economical and environment-friendly.

Owner:顾青林 +8

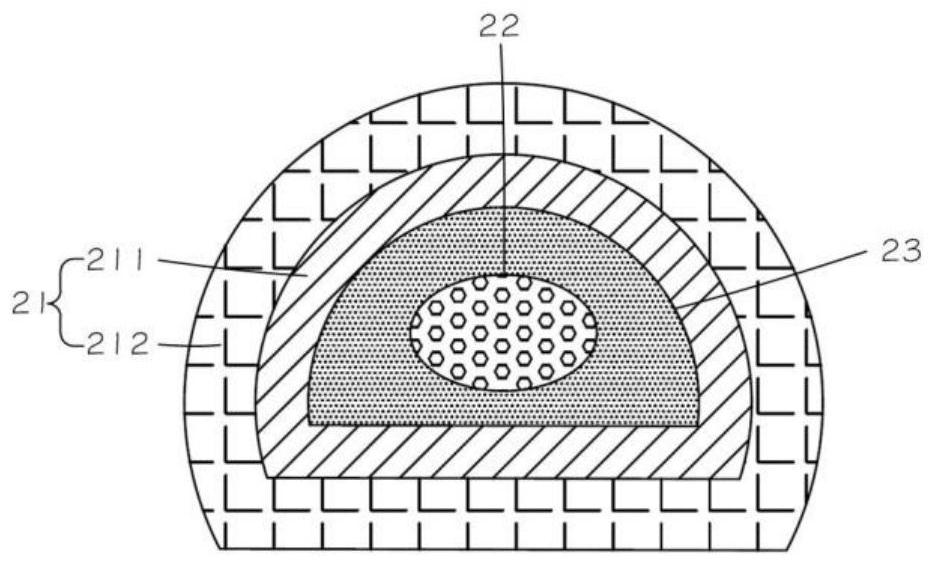

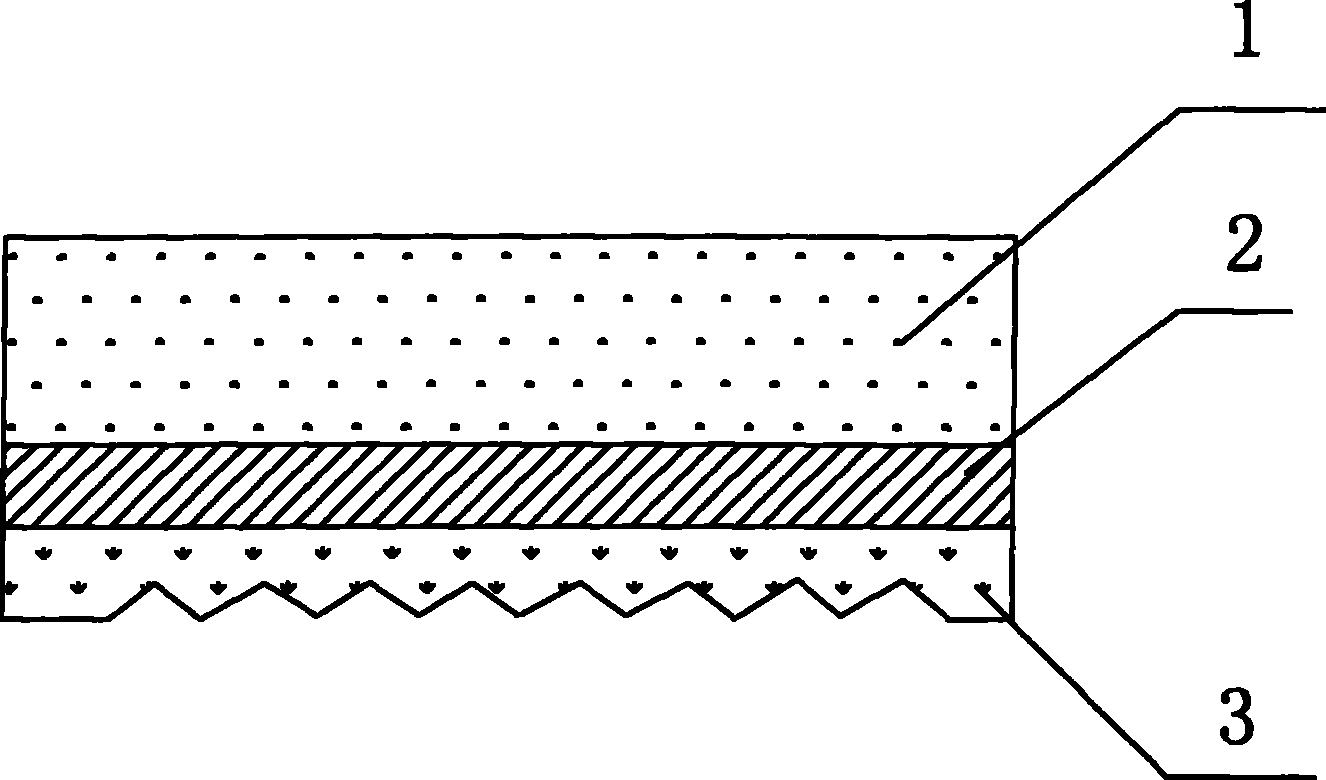

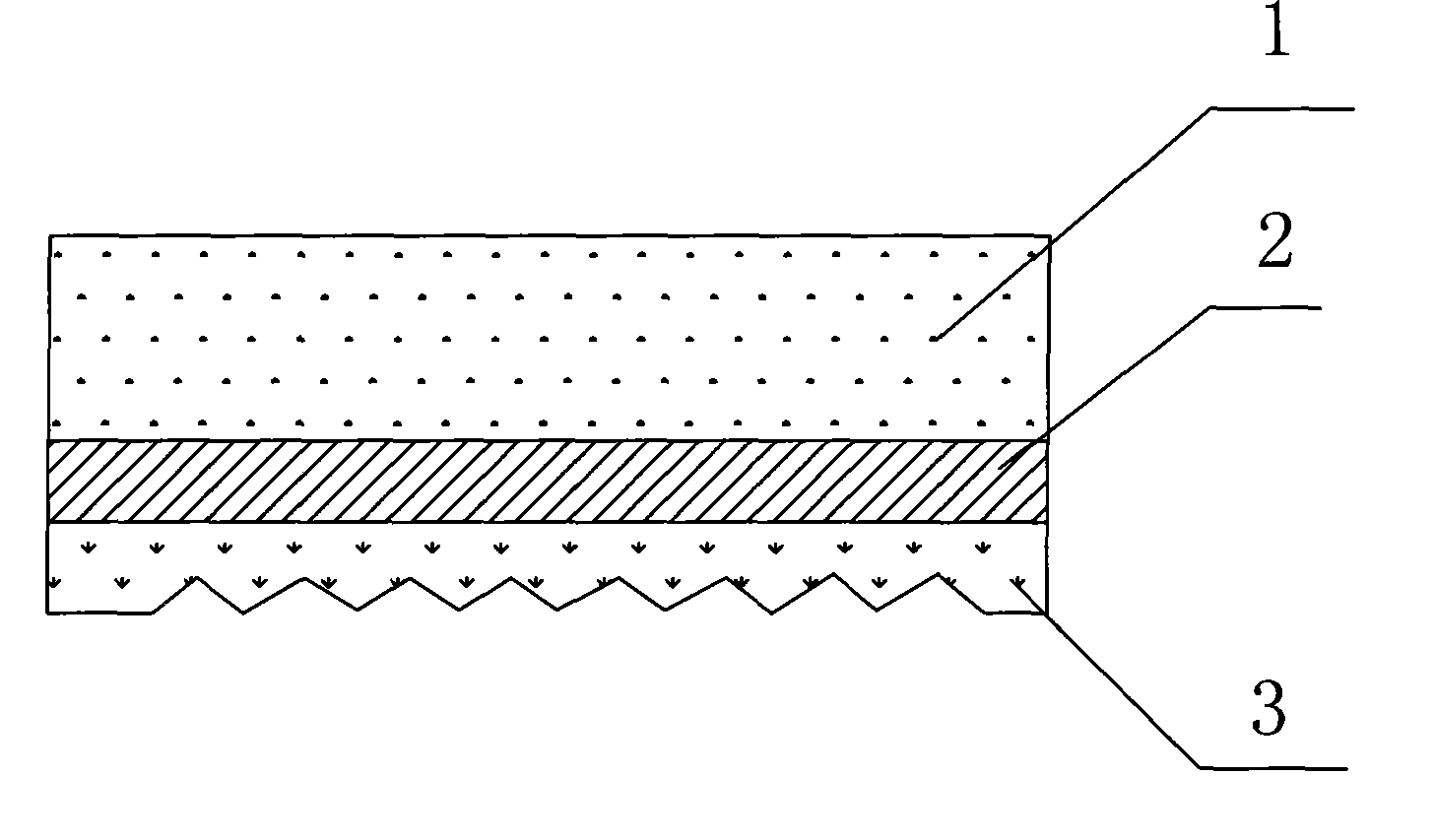

Preparation method of ceramic water permeable brick with multi-layer composite structure and ceramic water permeable brick

The invention relates to a preparation method of a ceramic water permeable brick with a multi-layer composite structure and the ceramic water permeable brick. The preparation method comprises the following steps: 1) crushing and screening ceramic wastes to obtain coarse aggregates, medium aggregates and fine aggregates with different particle sizes; 2) mixing the waste glass powder with kaolin, magnesium oxide, limestone and boric acid, carrying out ball milling and smelting, and carrying out water quenching, grinding and sieving to obtain binder powder; 3) spraying a water glass wetting agentto the medium aggregates, carrying out stirring and mixing, adding the binder powder, and carrying out rolling pelletizing to obtain a coating material; 4) mixing the coarse aggregates with the coating material to obtain a bottom layer material, and mixing the fine aggregates with a water glass wetting agent and the binder powder to obtain a surface layer material; and 5) arranging the bottom layer material, the coating material and the surface layer material from bottom to top in a layered manner, and carrying out pressing, molding and sintering. According to the ceramic water permeable brick, the surface layer and the bottom layer are connected through the middle layer, aggregate particle sizes and pores are gradually transited, the strength is high, the binding force is strong, damageand cracking are avoided after repeated cleaning with a high-pressure water gun, the water permeability is good, recovery is easy, and the service life is long.

Owner:卢俊杰

Environment-friendly charcoal for heating

The invention provides environment-friendly charcoal for heating. The prepared charcoal is applied to indoor heating, fresh fragrance is produced after the charcoal is burned, and the charcoal has lowpreparation cost, a dense texture and long burning time; a modified wood material which is adopted as a main raw material is prepared by modifying a wood material through diatomaceous earth and ironoxide, so that the viscosity, firmness and burning resistance of the raw material are increased, and molding of the charcoal is facilitated; therefore, the product does not crack and break easily, theburning time is increased, and the product quality can be improved.

Owner:和县伊迈炭业有限责任公司

Abrasion-resistant and high-strength archaized brick and preparation method thereof

The invention discloses an abrasion-resistant and high-strength archaized brick and a preparation method thereof, and relates to the technical field of archaized bricks. The abrasion-resistant and high-strength archaized brick is prepared from the following raw materials in parts: 45 to 55 parts of modified perlite, 25 to 35 parts of bluestone, 20 to 30 parts of acidified carbon fiber, 15 to 25 parts of fly ash, 15 to 25 parts of sodium feldspar, 5 to 10 parts of barium carbonate, 5 to 10 parts of enhancing agent, 5 to 10 parts of nanometer silicon dioxide, 3 to 6 parts of liquid paraffin, 3 to 6 parts of mica, 2 to 5 parts of adhesive, and 2 to 5 parts of coloring agent. The abrasion-resistant and high-strength archaized brick has the advantages that the compressive strength and heat insulation property are excellent, and the easiness in damage and cracking is avoided.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

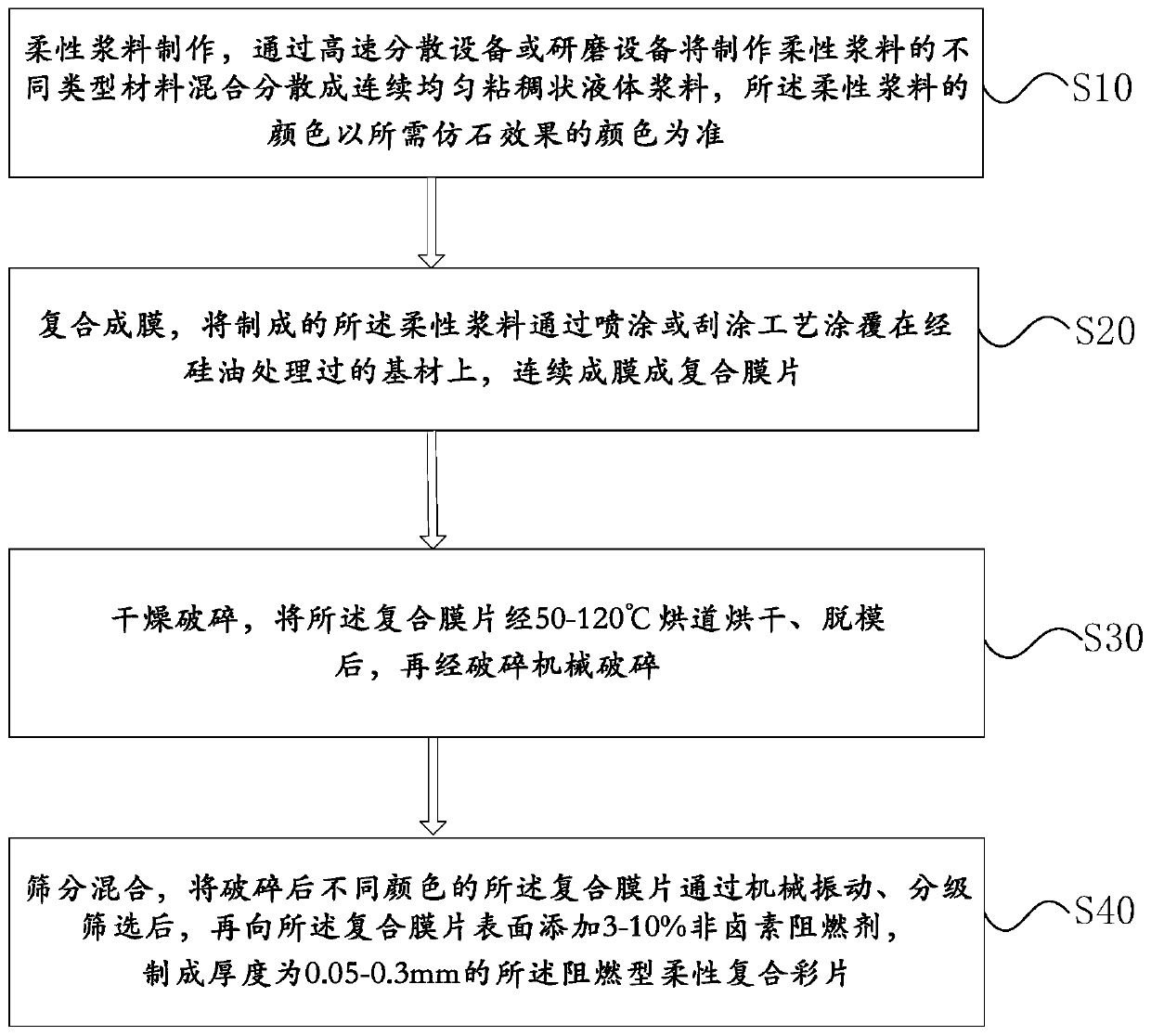

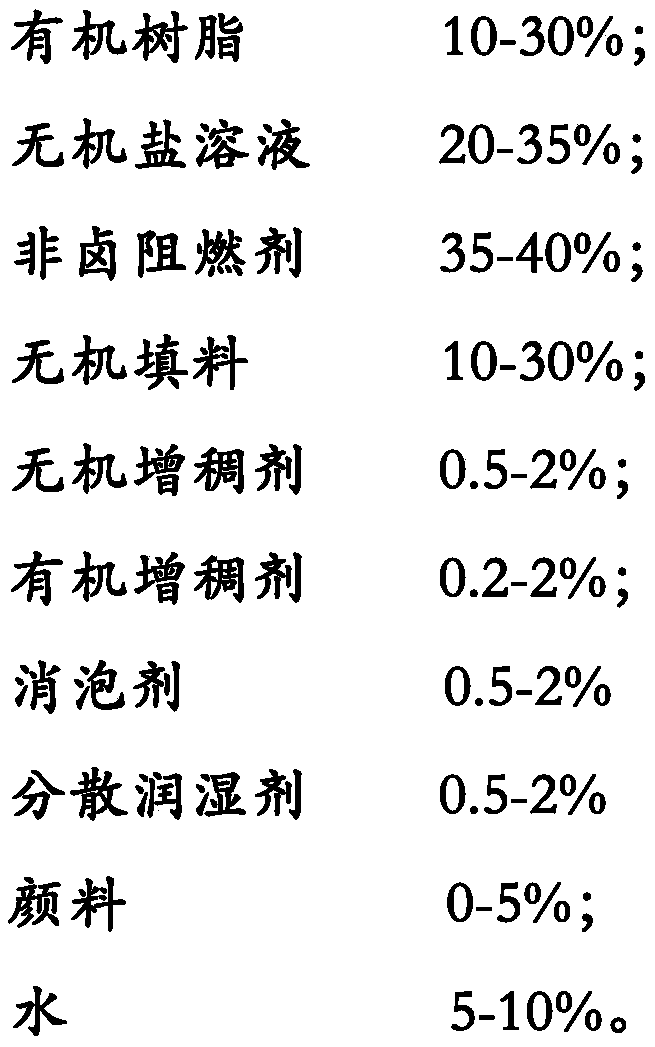

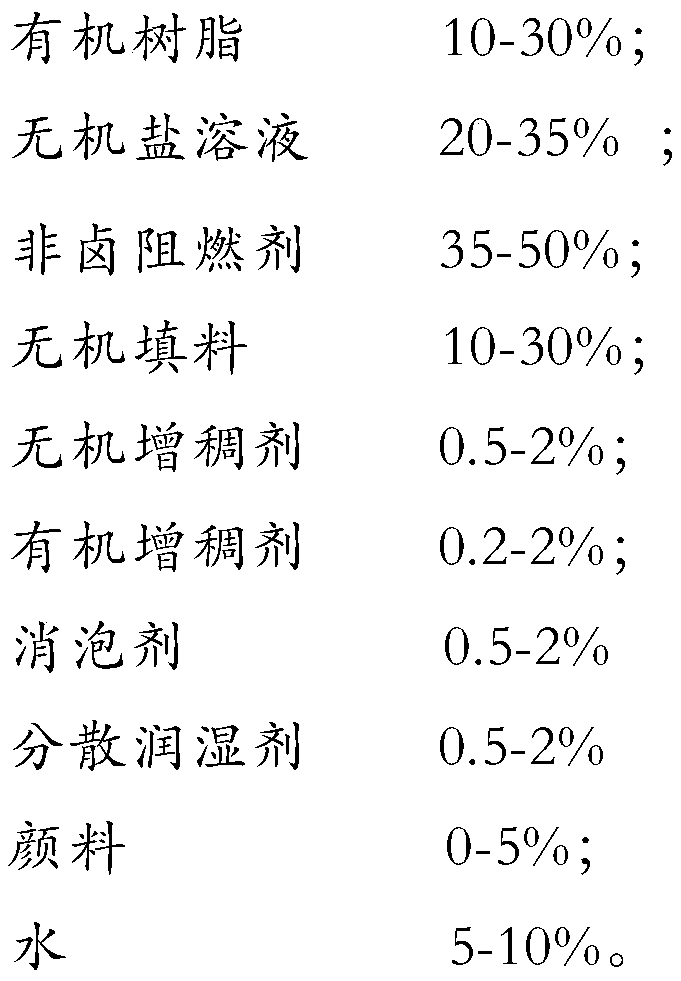

Flame retardant flexible composite color flake and preparation method thereof

InactiveCN109852128ALow calorific valueHigh oxygen indexFireproof paintsMulticolor effect coatingsOrganic filmSlurry

The invention provides a flame retardant flexible composite color flake and a preparation method thereof. The flame retardant flexible composite color flake is prepared by compounding a flexible slurry and a substrate, the flexible slurry mainly comprises organic resin 10-30%; inorganic salt solution 20-35%; non-halogen flame retardant 35-40%; inorganic filler 10-30%; inorganic thickener 0.5-2%; pigment 0-5%; and water 5-10%. According to the flame retardant flexible composite color flake provided by the invention, a plurality of kinds of inorganic substances such as an inorganic salt solution, an inorganic filler and an inorganic thickener are added into an organic film forming substance, with use of an inorganic modified resin compounding technology, the heat calorific value of combustion of the final composite color flake is greatly decreased and the flame retardancy of the composite color flake is improved, and meanwhile with the addition of the non-halogen flame retardant, the composite color flake is endowed with a higher oxygen index, the flame retardancy of the composite color flake is further improved, the toughness of the composite color flake is improved, the composite color flake is not easy to break and crack in actual use, and defects of prior art are overcome.

Owner:亚士创能新材料(滁州)有限公司

Antibacterial porcelain tooth composite material

InactiveCN110917042ANot easy to breed bacteriaNot easy to break and crackImpression capsDentistry preparationsCalcium carbonateCompositermes

The invention provides an antibacterial porcelain tooth composite material. The antibacterial porcelain tooth composite material is prepared from the following raw materials in parts by weight: 10-20parts of potassium feldspar, 6-13 parts of sodium carbonate, 5-12 parts of straw, 3-7 parts of boron, 2-6 parts of calcium carbonate, 3-8 parts of diopside and 10-18 parts of nanometer silver. The porcelain tooth made of the porcelain tooth composite material provided by the invention does not easily breed bacteria, is firm, is not easy to break and crack, and has long service life.

Owner:柳州市佛冠齿科数字化研发有限公司

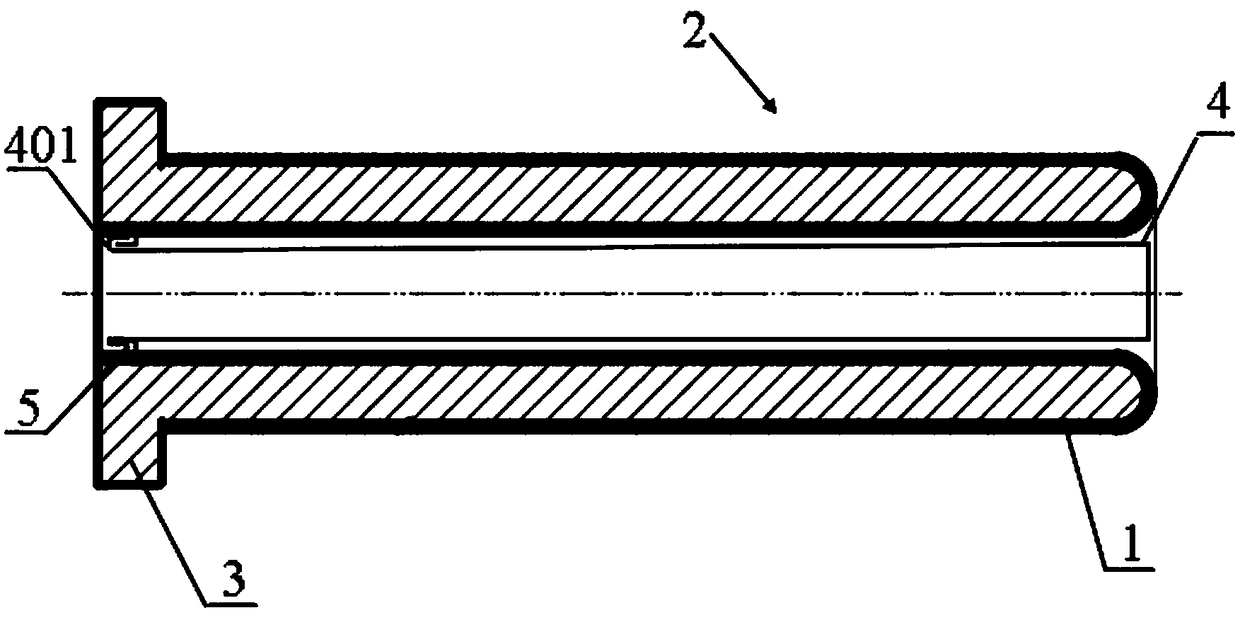

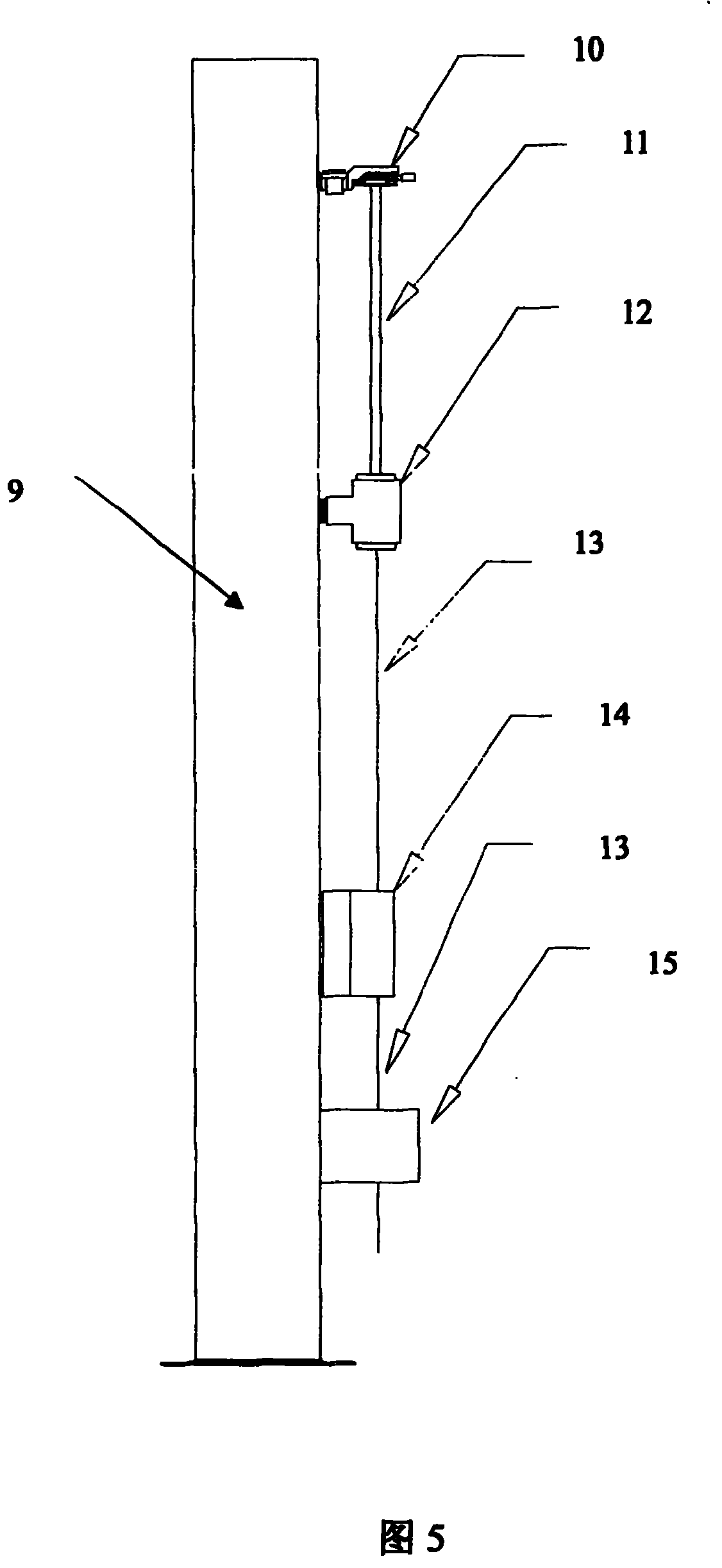

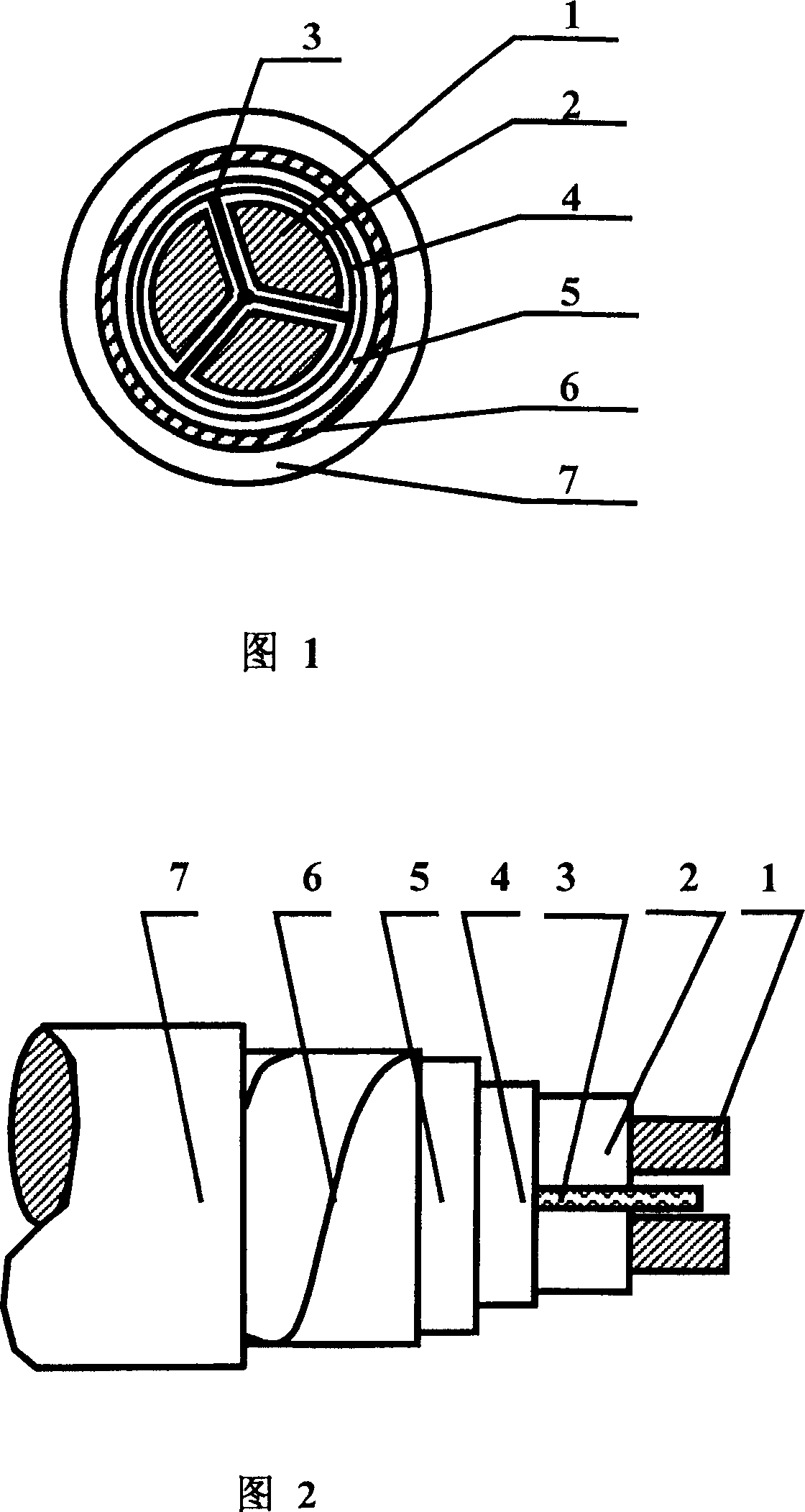

Method for fabricating quartz base plate of optical device

ActiveCN1872751BReduced dimensional accuracyEasy to processGlass reforming apparatusHigh volume manufacturingGraphite

This invention relates to a method for manufacturing quartz substrate for optical devices. The method comprises: (1) washing quartz rod or quartz tube, and fixing in a high temperature graphite oven; (2) introducing inert gas into the high temperature graphite oven; (3) pulling, wire-drawing and cutting the quartz rod or quartz tube to obtain quartz substrate. The method has such advantages as low cost, mass production, and high product quality.

Owner:深圳市天阳谷科技发展有限公司

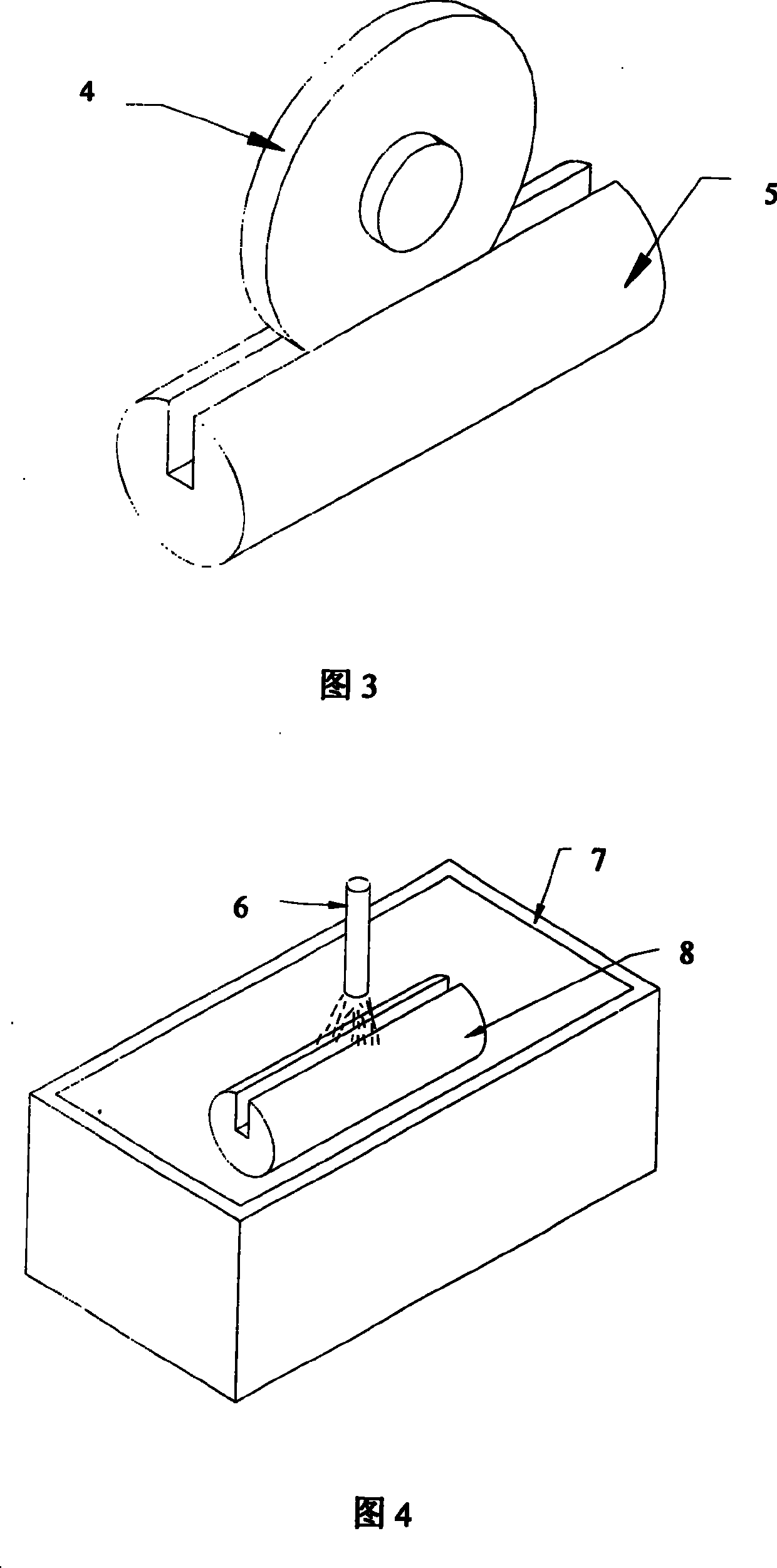

Environment protection high flame resistance fire control type cable

InactiveCN1322519CReduce releaseHigh flame retardant levelInsulated cablesInsulated conductorsInsulation layerAlkali free

A cable of high flame-retardant environmental protection and fire-fighting is composed of a single core or multiple cores wrapped with an XLPE insulation layer separately to become an insulation conductor filled with inorganic filling materials of asbestos base, the insulation conductor beam is covered with a betting layer, an oxygen-isolation layer, s steel belt layer and an outer protection layer orderly, among which, the belting layer is a lap-wound one bound by alkali-free glass silk belt layer is a galvanized one of double-layer gap winding, the oxygen-isolation layer and outer protection layer are high-molecular compounds with the olefine polymer as the basis mixed with hydra-hydroxide by a coupler.

Owner:CHANGSHA JINLONG CABLE

Chinese yam egg-yolk puff and preparation method thereof

InactiveCN113229310AElasticEnhance layeringDough-sheeters/rolling-machines/rolling-pinsDough embossing machinesBiotechnologyDried meat

The invention discloses a Chinese yam egg-yolk puff which comprises puff crust and stuffing and is characterized in that a Chinese yam wrapper layer is arranged between the puff crust and the stuffing, the mass ratio of the puff crust to the stuffing to the Chinese yam wrapper layer is 1: 2: 1, and the stuffing is prepared from the following raw materials in parts by weight: 80-95 parts of main materials and 5-20 parts of auxiliary materials, the main material is prepared by mixing one or more of duck egg yolk, dried meat floss, sweetened bean paste and shredded coconut stuffing, and the auxiliary materials are one or more of water, butter and corn oil. The invention further discloses a preparation method of the Chinese yam egg-yolk puff, in the process of rolling the wrappers through a dough rolling machine, the wrappers can be embossed at the same time, multiple purposes are achieved at one stroke, the cost is effectively reduced, and the product characteristics and competitiveness are improved.

Owner:RUICHANG YIXIANG AGRI PROD

A kind of production method of non-combustible decorative board

The invention relates to a method for making a non-combustible decorative board. The base material is made of a mixture of pulverized coal slag, quartz powder and lime in a granular state. The quartz powder has obvious guiding properties to the mechanical properties of the product and can improve the nail-holding force of the base material. ;Quartz powder itself is not easy to bond. Lime is an air-hardening inorganic gelling material with calcium oxide as the main component. The addition of lime effectively solves the problem that quartz powder is difficult to bond and form, making the substrate have good plasticity; Coal slag particles have good granularity, and are used as aggregate in the mixture of coal slag, lime and quartz powder to support and solidify the formed substrate; coal slag is formed in the mixture of quartz powder, lime and fiber The three-dimensional space structure is conducive to the flow of phenolic resin, ensuring that the fiber will not be deformed due to the flow pressure generated by the injection of the resin, thus ensuring the uniformity of the voids in the fiber prefabricated substrate.

Owner:江苏天润盛凯新材料股份有限公司

Xenotype abrasion-proof ceramic block with rubber and its preparing method

InactiveCN101157290BSimple structureEasy to manufactureLamination ancillary operationsLaminationPolymer scienceAdhesive

The invention relates to a deformed wear-resistant ceramic block with rubber and the manufacturing method thereof. The invention is characterized in that a rubber layer, a metal sheet and a deformed ceramic block are arranged in sequence and then are vulcanized and adhered into a whole to obtain the deformed ceramic block with rubber. The detail producing method includes the following steps: A. ametal sheet is selected, the geometry size of the metal sheet is as same as that of the sticking surface of the deformed ceramic block; B. the high-temperature-resistance rubber is directly vulcanized onto the metal sheet by a vulcanizing steel die; C. the sticking surfaces of the metal sheet and the deformed ceramic block are cleaned, the mixed general high-temperature adhesive which can be bought in market is coated on the sticking surfaces which can be adhered into a whole in this way, the deformed wear-resistant ceramic block is obtained after the high-temperature adhesive is solidified. The invention has the advantages of simple structure, easy processing method, performances of wear and tear resistance, high temperature resistance of 300 DGE C and impact resistance, as well as good strength, thereby being not easy to be broken and peeled, thus the service life of the invention is greatly prolonged.

Owner:湖南泰鑫瓷业有限公司

Heat-insulating and heat-preserving flower pot for planting plants and manufacturing method thereof

ActiveCN107371862BLight in massVarious shapesSynthetic resin layered productsDomestic containersFiberThermal insulation

The invention discloses a heat-insulated flowerpot for planting plants. The flowerpot includes a pot body for storing nutrient soil required for planting plants, and a pot cover arranged at the upper edge of the pot body. The pot cover is a For the cover that can be opened and closed, the two covers are connected to the upper edge of the basin body through hinges; the basin body is composed of an acrylic layer, a perlite mixed resin layer and an FRP fiber layer from the outside to the inside, and the acrylic layer is mixed with the perlite. There is an adhesive layer between the resin layers and between the perlite mixed resin layer and the FRP fiber layer to prevent the two layers from falling off and separating; the thickness of the acrylic layer is 0.5 to 2.5mm, and the perlite mixed resin layer The thickness of the layer is 20~30mm, and the thickness of the FRP fiber layer is 0.5~2.5mm. The invention uses expanded perlite ceramsite with closed pores on the surface as the insulation material to produce a product with light weight and good thermal insulation effect. At the same time, the invention also provides a manufacturing method for preparing and using surface closed-pore expanded perlite ceramsite to manufacture heat-insulating flowerpots.

Owner:广东盛达穗南环保科技有限公司

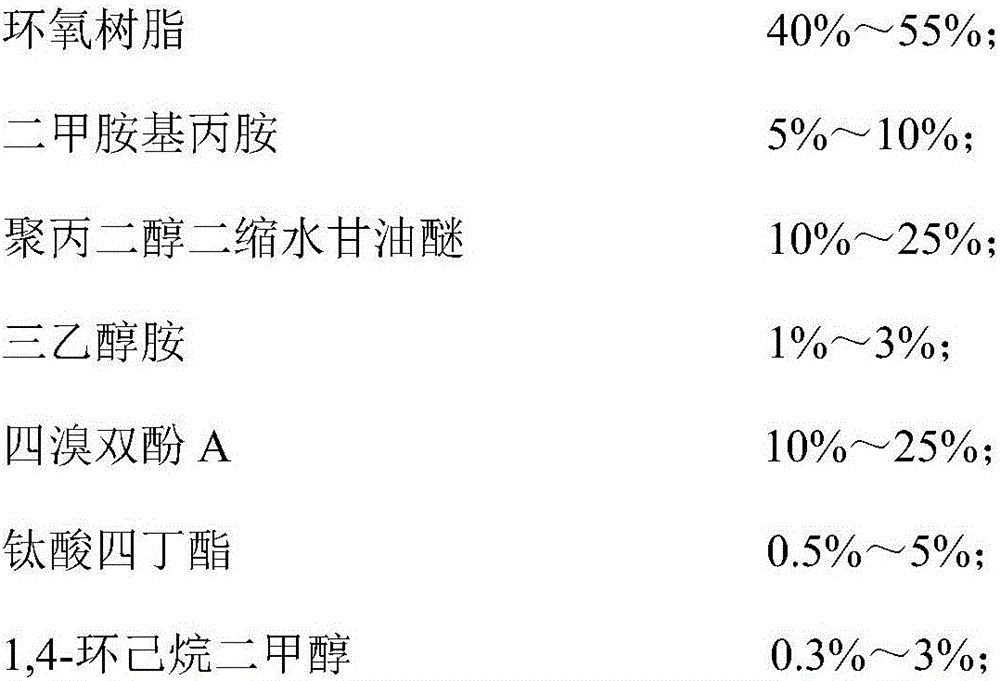

Insulating plate in stable form and manufacturing method thereof

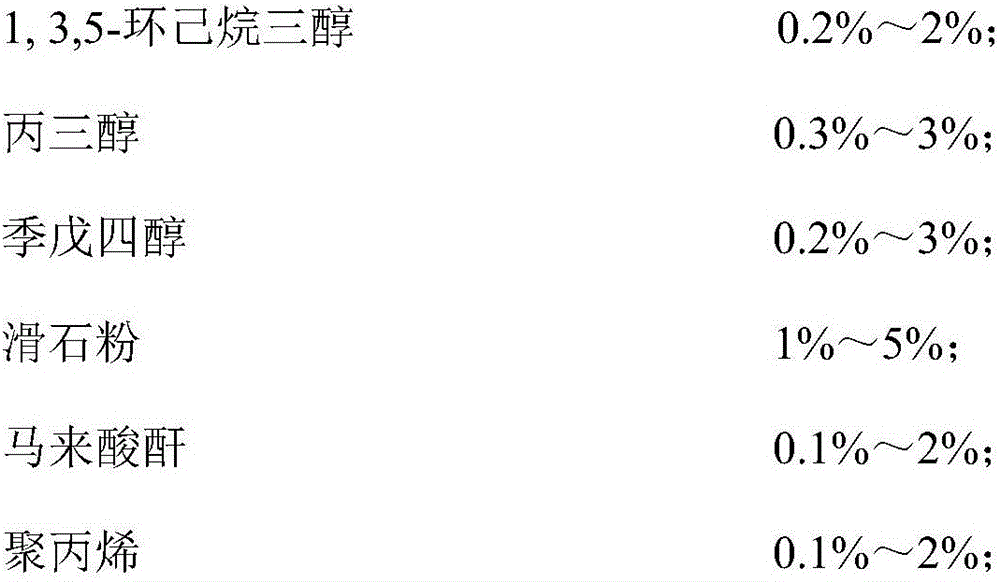

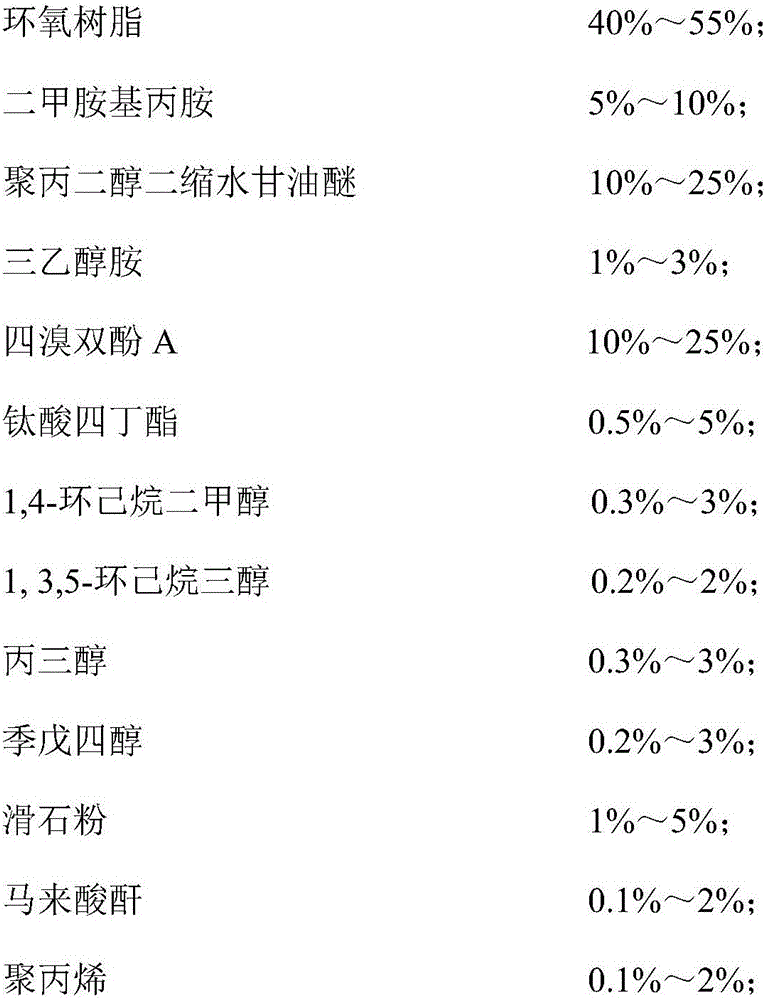

The invention discloses an insulating plate in a stable form. The insulating plate is prepared from the following materials by mass percent: 40% to 55% of epoxy resin, 5% to 10% of dimethylaminopropylamine, 10% to 25% of polypropylene glycol diglycidyl ether, 1% to 3% of triethanolamine, 10% to 25% of tetrabromobisphenol A, 0.5% to 5% of tetrabutyl titanate, 0.3% to 3% of 1,4-cyclohexanedimethanol, 0.2% to 2% of 1,3,5-cyclohexanetriol, 0.3% to 3% of glycerol, 0.2% to 3% of pentaerythritol, 1% to 5% of talcum powder, 0.1% to 2% of maleic anhydride and 0.1% to 2% of polypropylene. According to the insulating plate, a conventional epoxy resin insulating plate is modified, the maleic anhydride and styrene which are used for improving the toughening performance are added, and additionally, a proper amount of talcum powder is added, so that the deformation of the insulating plate due to heating or cooling is reduced.

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

Water-containing softly-embedded section specimen and manufacturing method thereof

ActiveCN110558308AEmbedding will no longer come out to affectGood flexibilityDead animal preservationEducational modelsResin embeddingEngineering

The invention relates to a water-containing softly-embedded section specimen and a manufacturing method thereof, and belongs to the technical field of biological resin embedded sections. The manufacturing method of the water-containing softly-embedded section specimen comprises the following steps: freezing a biological specimen, sawing the biological specimen to for sheet section specimens, and soaking the section specimens in a water treatment agent for moisture treatment to obtain pretreated section specimens after the soaking is finished; putting the pretreated section specimens to a mold,and pouring a soft embedding agent into the mold at a non-initiation temperature, wherein the soft embedding agent has flexibility after being cured; and performing curing at an initiation temperature after the pouring is finished to obtain the product. The section specimens are soaked in the water to completely lock the water in the section specimens, so the water cannot flow out to influence embedding. The water is locked in the section specimens, so that the original state of biological tissues can be retained, and the state of the biological tissues can be truly reproduced.

Owner:HENAN ZHONGBO BIO PLASTINATION TECHN CO LTD

Moisture-containing soft-embedded cross-section specimen and its preparation method

ActiveCN110558308BEmbedding will no longer come out to affectGood flexibilityDead animal preservationEducational modelsOrganismMechanical engineering

The invention relates to a moisture-containing soft-embedded cross-section specimen and a preparation method thereof, belonging to the technical field of bio-resin embedded cross-sections. The method for making the moisture-containing soft-embedded cross-section specimen comprises the following steps: freezing the biological specimen and sawing the sliced cross-section specimen, soaking the cross-section specimen in a water treatment agent for water treatment, and obtaining The pretreated cross-section specimen; the pretreated cross-section specimen is placed in the mold, and the soft embedding agent is poured into the mold at a non-initiating temperature. The soft embedding agent has flexibility after curing; Cured, that is. By immersing the cross-section specimen in water, the water in the cross-section specimen can be completely locked, and the water will not come out to affect the embedding. Moreover, the water is locked in the cross-section specimen, which can retain the original state of the biological tissue and reproduce the state of the biological tissue more realistically.

Owner:HENAN ZHONGBO BIO PLASTINATION TECHN CO LTD

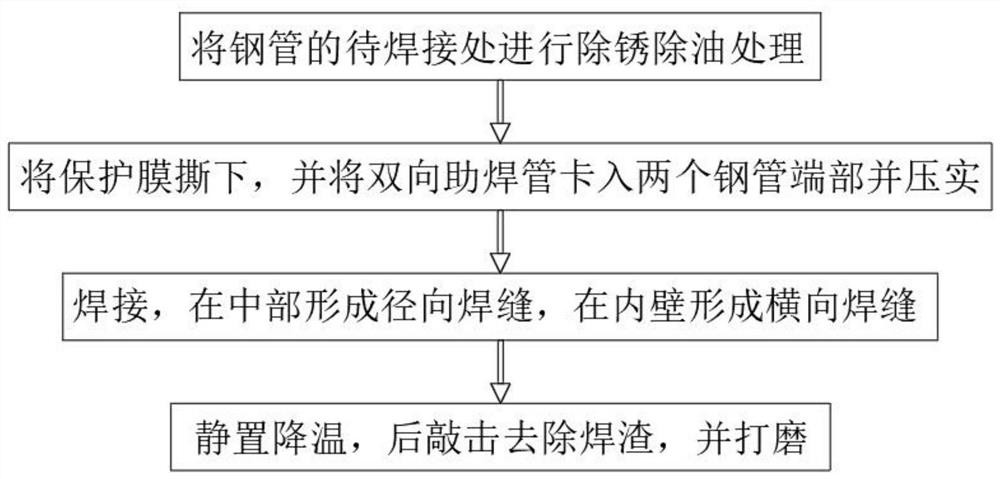

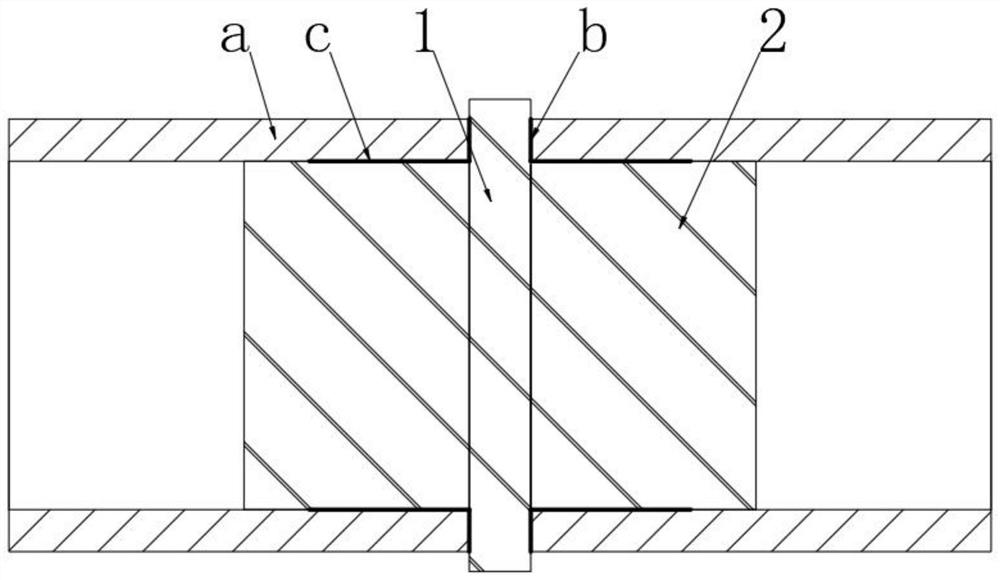

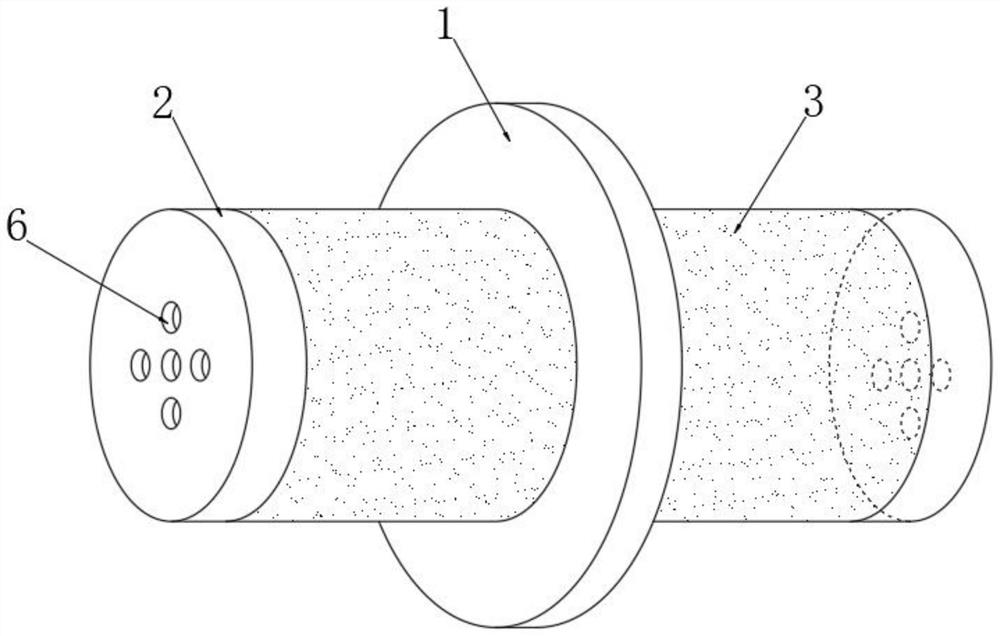

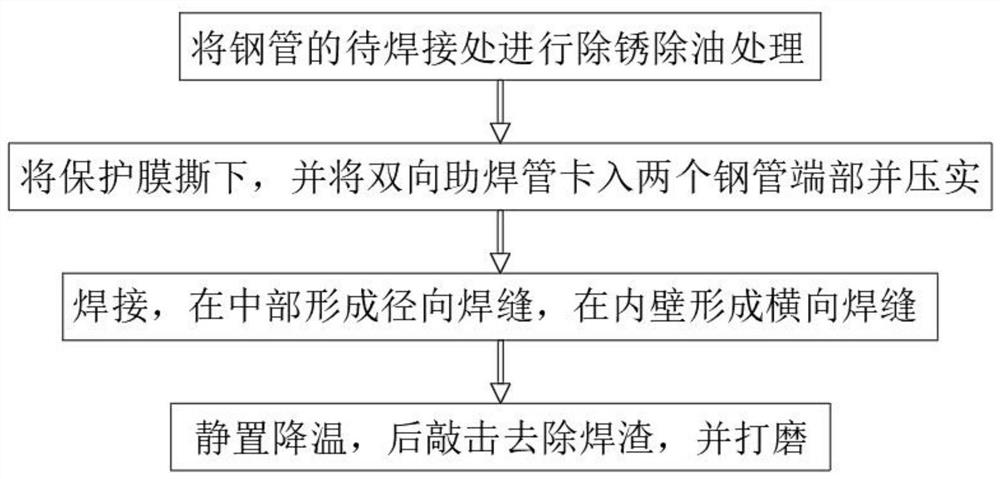

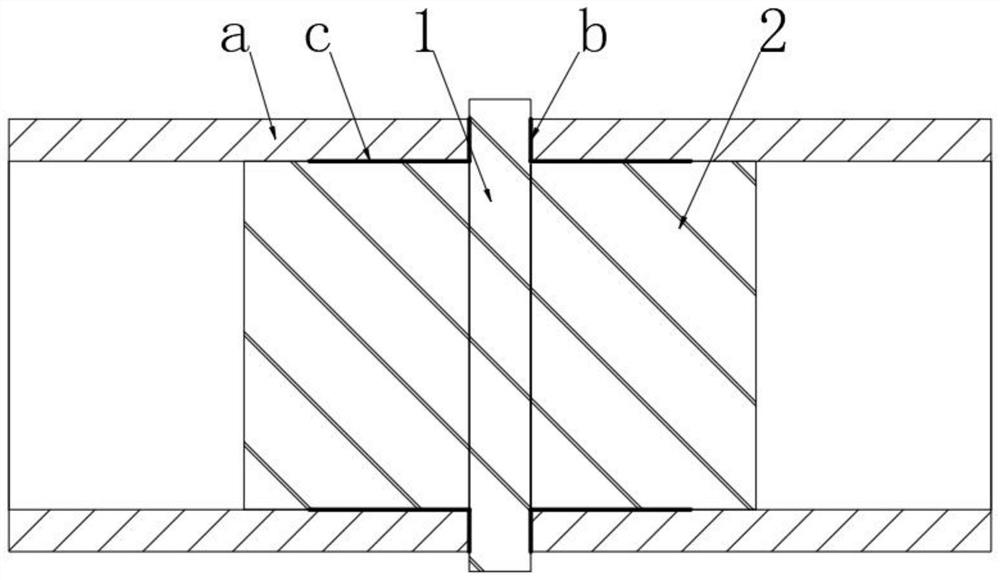

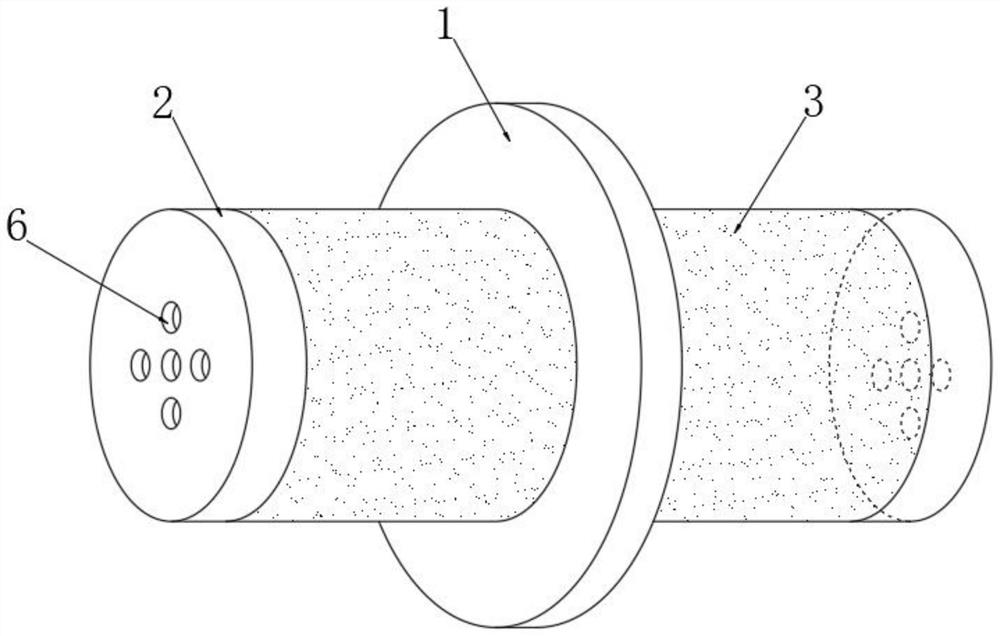

Steel pipe embedded type bidirectional welding process

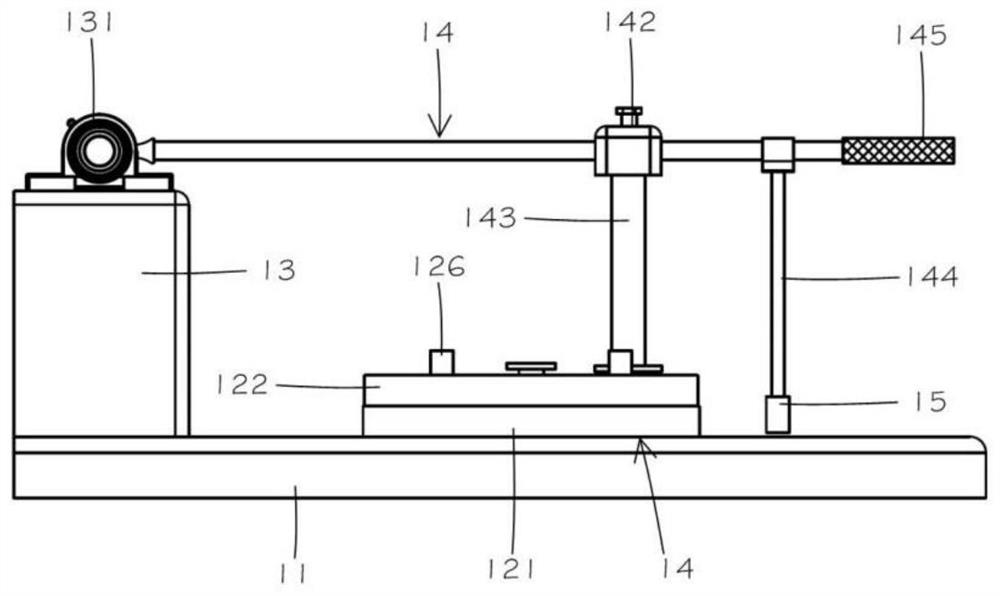

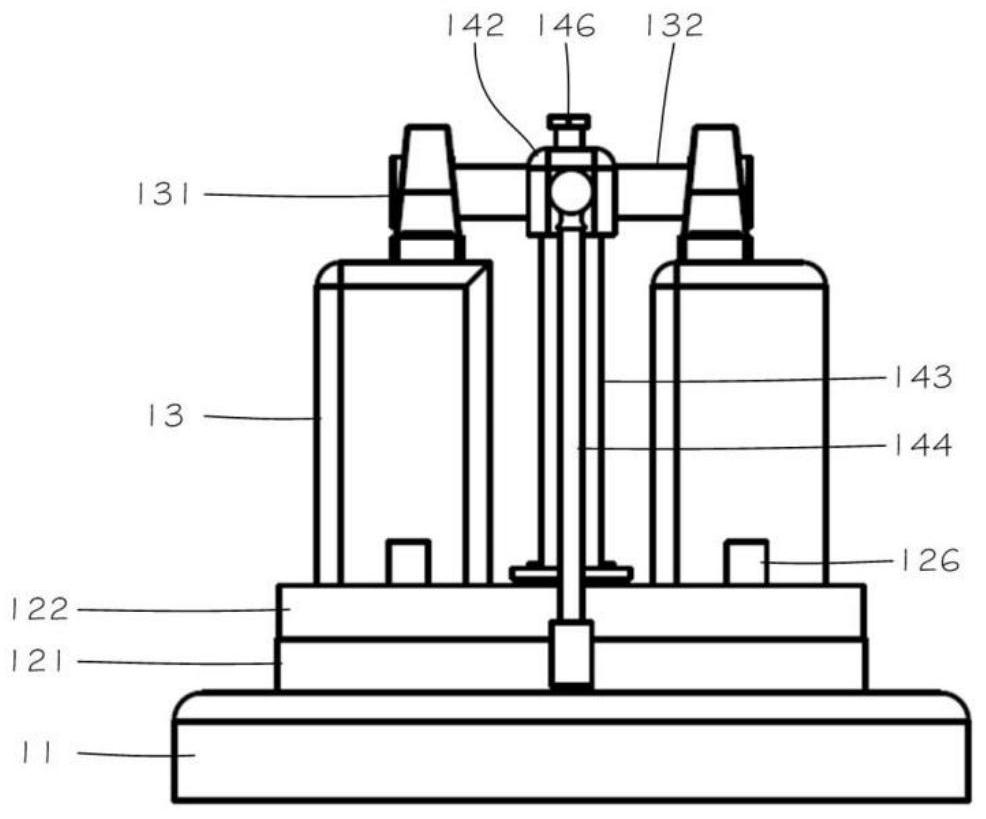

ActiveCN113070596ANot easy to break and crackNot easy to burstWelding/cutting auxillary devicesAuxillary welding devicesWeld seamWeld strength

The invention discloses a steel pipe embedded type bidirectional welding process, and belongs to the field of welding. According to the steel pipe embedded type bidirectional welding process, through the arrangement of a bidirectional welding assisting pipe, during high-temperature welding, an outer wrapping welding piece can form a radial welding seam on the sections of two steel pipes, inner welding powder blocks are melted and make contact with the inner walls of the steel pipes after being heated, and a transverse welding seam can be formed inside. Compared the prior art in which only a radial welding seam is formed, the welding strength is remarkably improved, and the welded steel pipes are not prone to cracking or breaking. Meanwhile, in cooperation with a temporarily sealed environment in transverse welding pipes, high-thermal-conductivity gas expands after being heated. On one hand, the molten inner welding powder blocks are pushed through metal elastic pieces, then welding layers formed by the molten inner welding powder blocks and the inner walls of the steel pipes are more compact and stable, and the welding strength is further improved; and on the other hand, the high-thermal-conductivity gas pushes hollow pre-sealing balls to make the hollow pre-sealing balls separated from the transverse welding pipes to finish the airtightness of the transverse welding pipes, and the situation that the transverse welding pipes explode due to excessive expansion of the expanded high-thermal-conductivity gas is effectively avoided.

Owner:河北方泉管道装备有限公司

An embedded two-way welding process for steel pipes

ActiveCN113070596BNot easy to break and crackNot easy to burstWelding/cutting auxillary devicesAuxillary welding devicesWeld seamWeld strength

The invention discloses a steel pipe embedded two-way welding process, which belongs to the field of welding. A steel pipe embedded two-way welding process, through the arrangement of two-way welding aid pipes, during high-temperature welding, the outer welding sheet can be formed on the cross-section of two steel pipes Radial welding seam, after heating, the inner welding powder block melts and contacts with the inner wall of the steel pipe, and can form a transverse weld seam inside. Compared with the radial weld seam in the prior art, the welding strength is significantly improved, and the welded steel pipe is not easy to weld. Cracking and breaking, and at the same time, in conjunction with the temporarily sealed environment in the horizontal welded pipe, the high thermal conductivity gas expands after being heated. On the one hand, the molten inner welding powder is pushed by the metal shrapnel, so that the welding layer formed by the molten inner welding powder and the inner wall of the steel pipe is more dense. It is stable and further improves the welding strength. On the other hand, the high thermal conductivity gas pushes the hollow pre-sealed ball to separate it from the horizontal welded pipe and contact the sealing performance of the horizontal welded pipe, effectively preventing the high thermal conductivity gas from expanding and causing the transverse welded pipe to burst due to excessive expansion.

Owner:河北方泉管道装备有限公司

Manufacturing method for non-combustible decorative plate

The invention relates to a manufacturing method for a non-combustible decorative plate. A base material is prepared from a mixture of pulverized coal residues in a granular state, quartz powder and lime, and the quartz powder has an obvious guiding property to the mechanical property of a product, so that the nail-holding ability of the base material can be improved. The quartz powder is unlikelyto bond, and a problem that the quartz powder is hard to bond and form is solved effectively by adding the lime as an air hardening inorganic bond material by taking calcium oxide as a main component,so that the base material has good plasticity. The pulverized coal residue granules have good granularity and are taken as an aggregate in mixing the pulverized coal residues, the lime and the quartzpowder, thereby playing supporting and curing roles to the formed base material. The pulverized coal residues form three-dimensional spatial structures in the mixture of the quartz powder, the lime and fibers to facilitate flow of phenolic resin and the fibers do not deform as a result of a flowing pressure generated by injecting resin, so that gaps in the fiber prefabricated base material are uniform.

Owner:江苏天润盛凯新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com