Xenotype abrasion-proof ceramic block with rubber and its preparing method

A technology of wear-resistant ceramics and production methods, applied in the direction of ceramic layered products, rubber layered products, chemical instruments and methods, etc., can solve the problem of easy cracking and breaking of ceramics, and can not solve the problem of bonding special-shaped ceramic blocks and temperature-resistant rubber, Inability to withstand high temperatures above 150°C for a long time, etc., to achieve the effect of not easy to crack and break, simple structure, and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

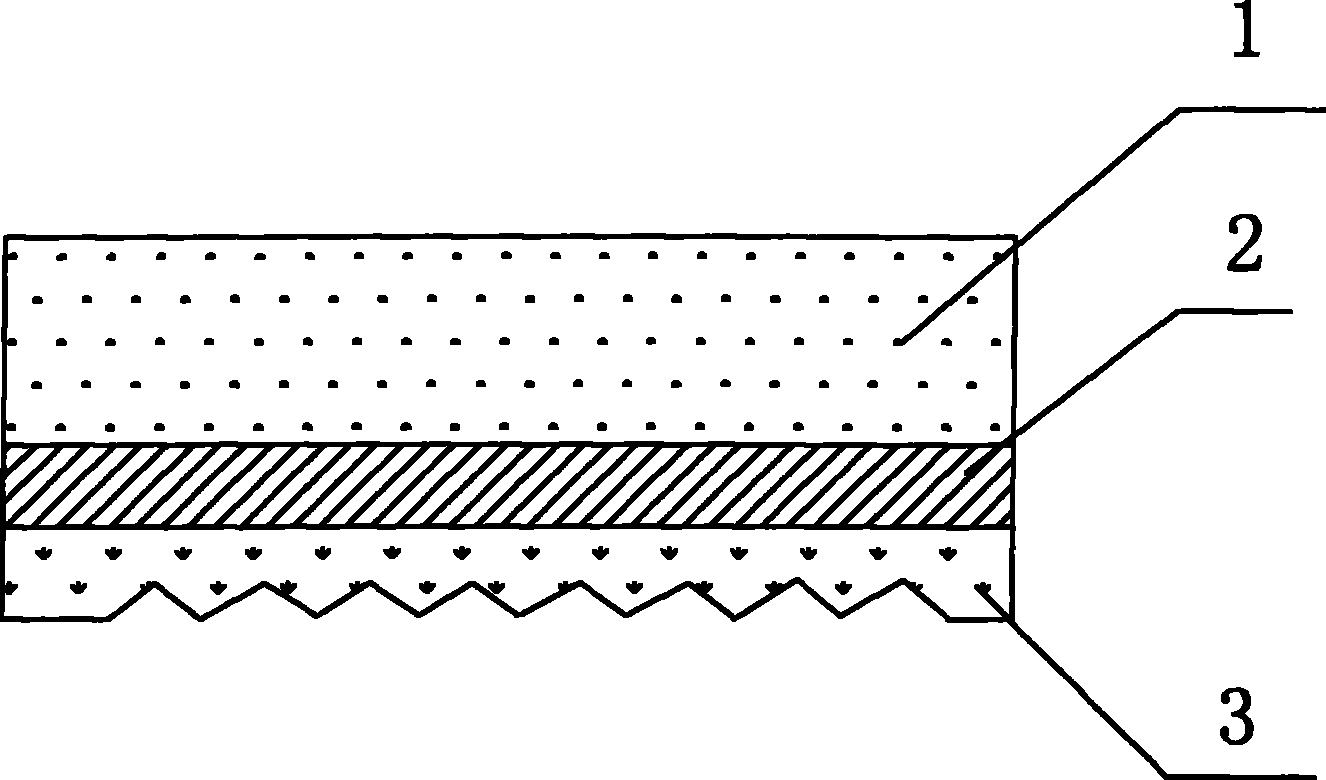

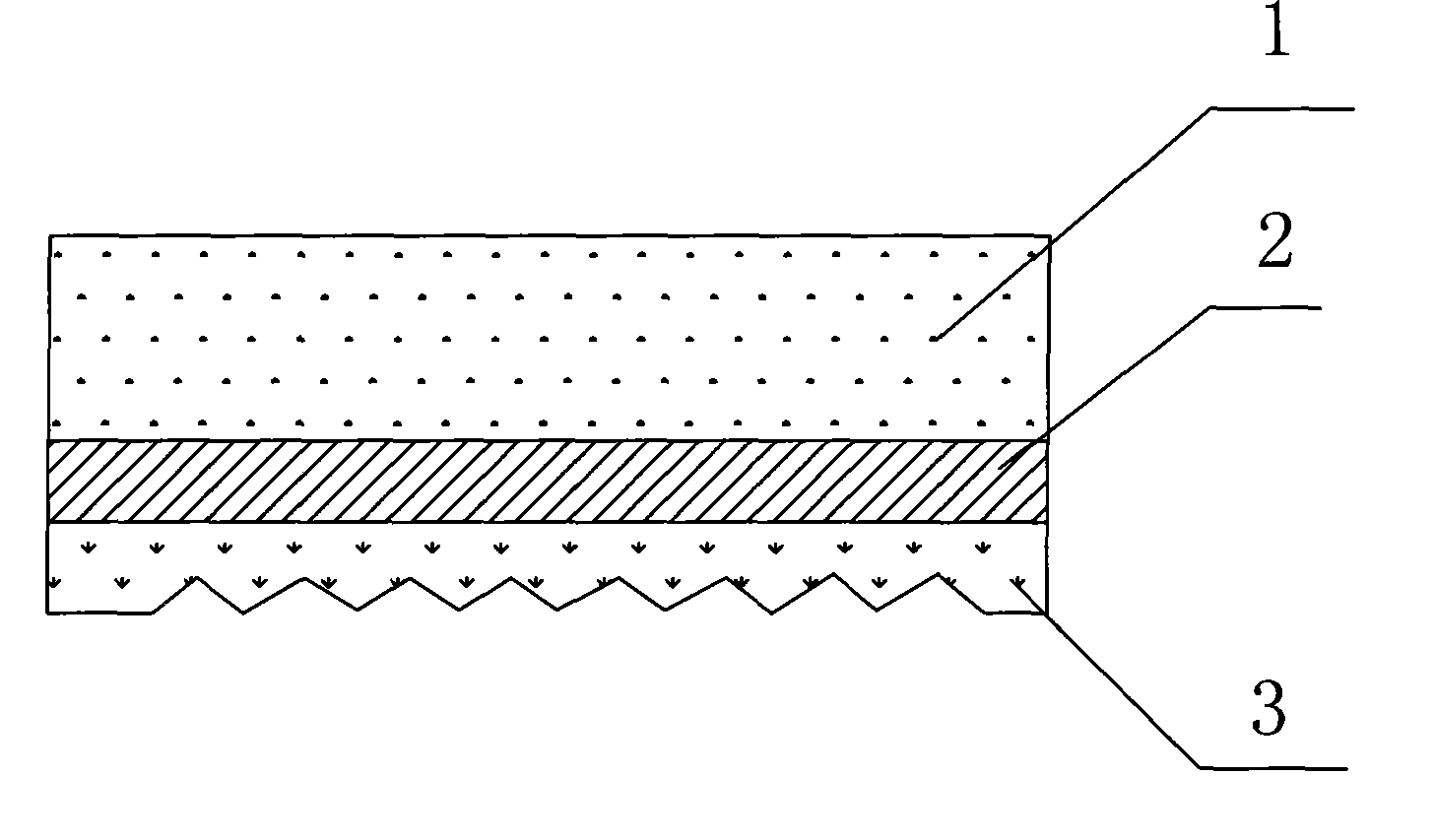

[0013] Referring to Fig. 1, a kind of production method of the special-shaped wear-resistant ceramic block with rubber is characterized in that the special-shaped ceramic block with rubber is arranged successively by rubber layer 1, metal sheet 2 and three kinds of materials of special-shaped ceramic block, The specific production steps are as follows:

[0014] A, select the metal sheet 2 with the same geometric size as the bonded surface of the special-shaped ceramic block 3;

[0015] B. Use a vulcanized steel mold to directly vulcanize the high temperature resistant rubber onto the metal sheet 2;

[0016] C. Clean the bonding surface of the metal sheet 2 and the special-shaped ceramic block 3, prepare it with ordinary commercially available high-temperature adhesive glue, apply it, and then bond it into one body. After the high-temperature adhesive glue is cured, it becomes a rubberized Shaped wear-resistant ceramic block.

[0017] The ceramic block made by placing the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com