Heat-insulating and heat-preserving flower pot for planting plants and manufacturing method thereof

A heat insulation and manufacturing method technology, applied in the direction of botany equipment and methods, plant protection, plant protection cover, etc., can solve the problems of poor heat preservation effect of perlite, easy water, difficult to meet the heat insulation materials of flower pots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

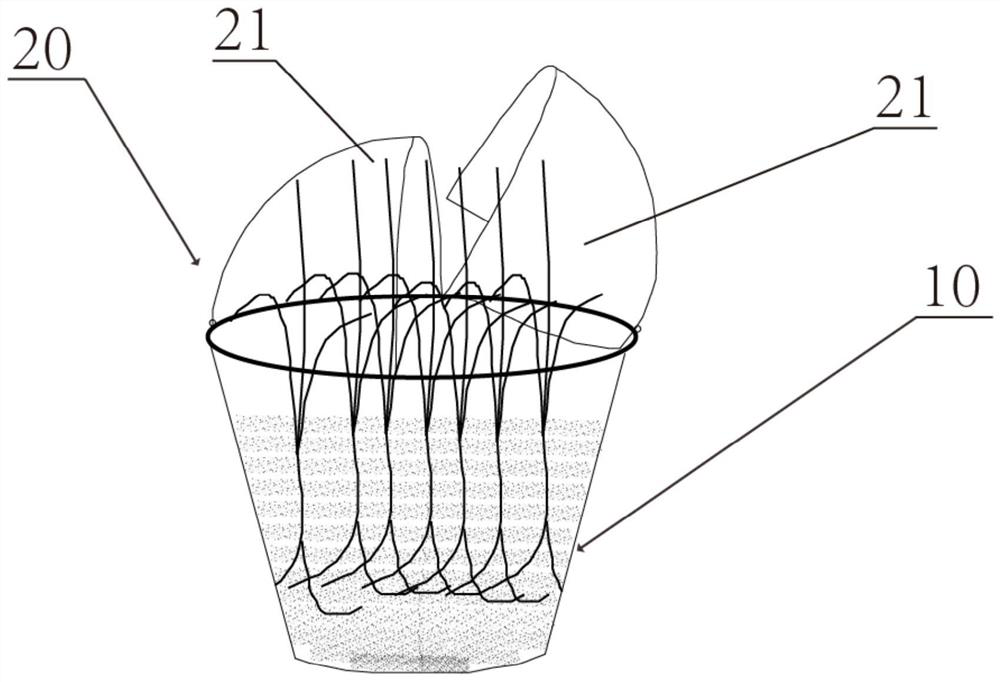

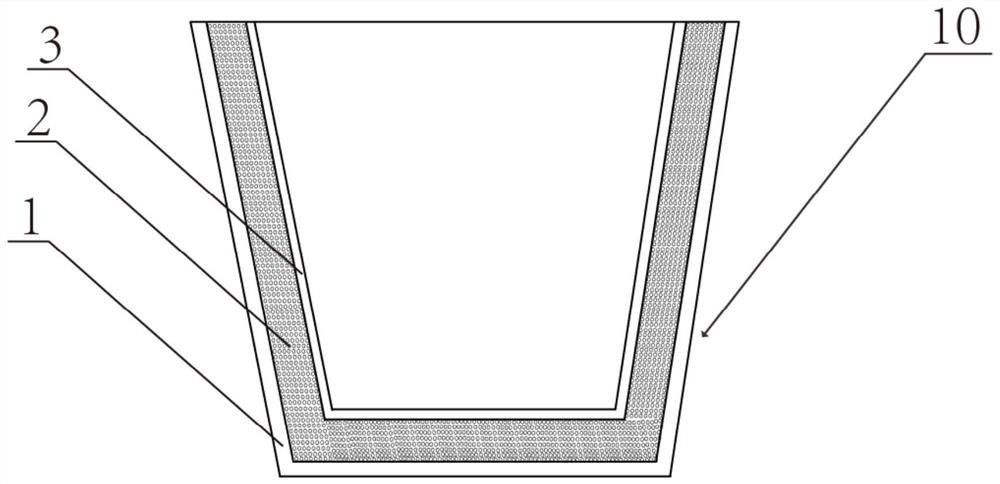

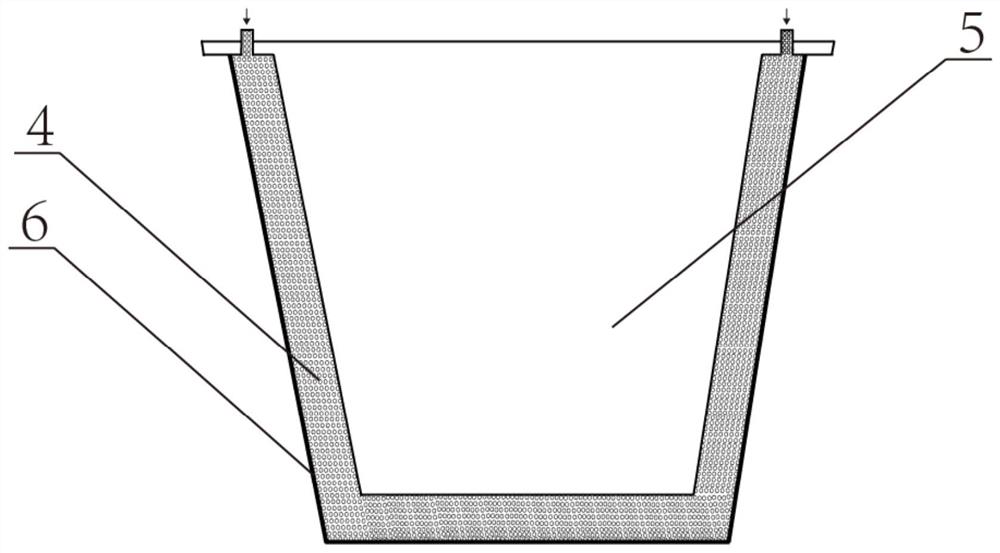

[0034] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment, wherein, the direction of the present invention is with figure 1 as standard.

[0035] Such as Figure 1 to Figure 2 Shown, the thermal insulation flowerpot for planting plants of the present invention, it comprises the basin body 10 of the layered structure that is made of multi-layer structure and pot cover 20, and basin body 10 is used for depositing the nutrient soil needed for planting plants, and pot From the outside to the inside of the body 10 (from the outer surface of the basin body 10 to the inner surface of the pelvic cavity), there are acrylic (polymethyl methacrylate PMMA) layer 1, perlite mixed resin layer 2 and FRP fiber (reinforced composite material) layer 3, Among them, the thickness of the acrylic layer 1 is 0.5-2.5 mm, the thickness of the perlite mixed resin layer 2 is 20-30 mm, the thickness of the FRP fiber layer 3 is 0.5-2.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com