Steel pipe embedded type bidirectional welding process

A welding process, built-in technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of reduced welding strength and easy fracture of two steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

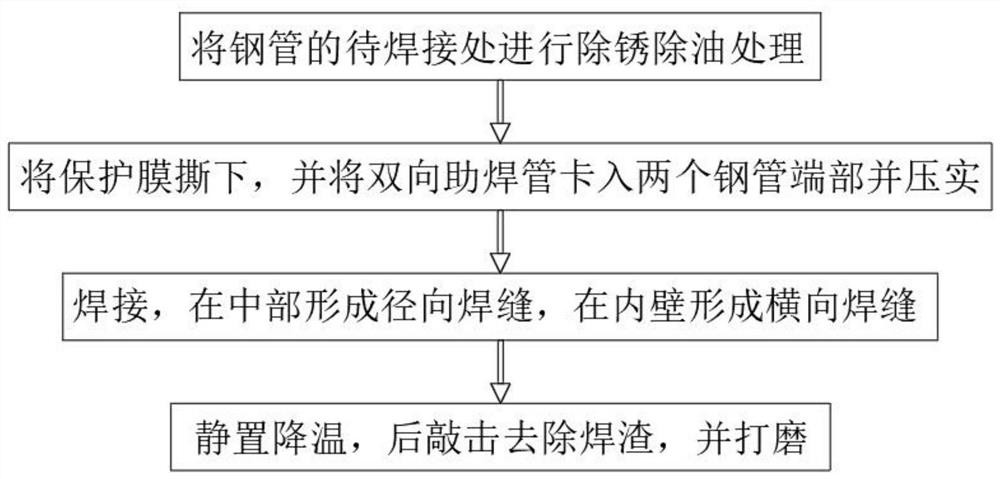

[0049] see figure 1 , a steel pipe embedded two-way welding process, comprising the following steps:

[0050] S1. First, derust and degrease the steel pipe to be welded, and clean and dry it;

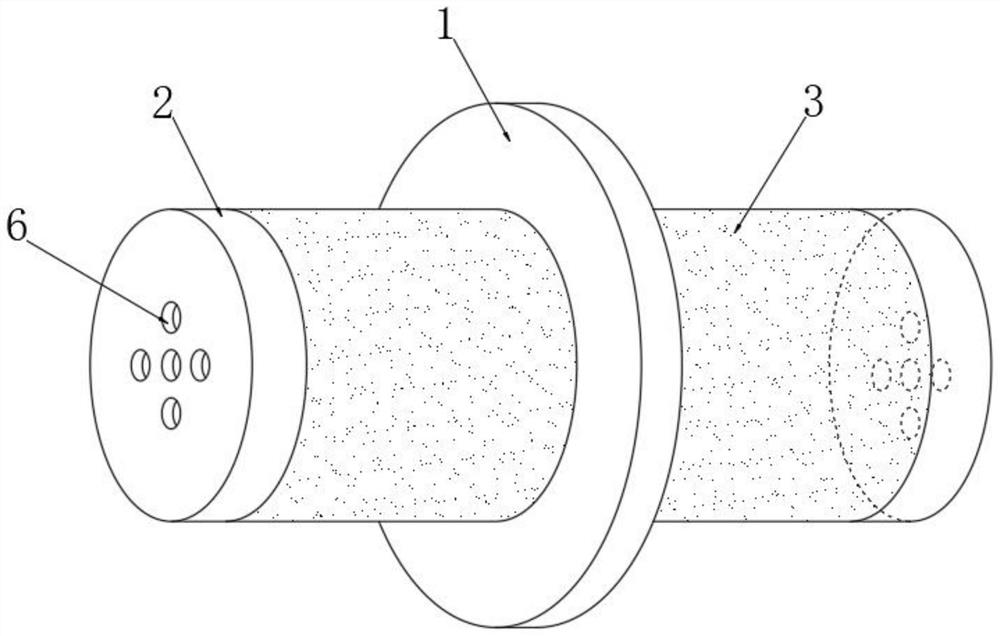

[0051] S2. Tear off the protective film on the outer surface of the two-way fluxing pipe, then snap one end of it into the end of the steel pipe to be welded, snap another steel pipe to be welded into the other end of the two-way fluxing pipe and compact it;

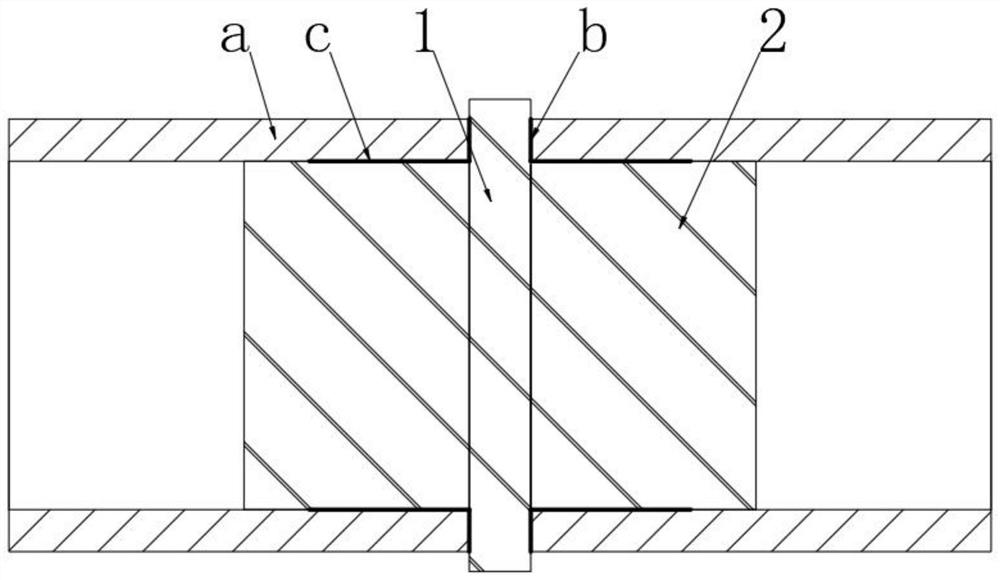

[0052] S3, see figure 2 , in the figure a represents the steel pipe, b represents the radial weld, and c represents the transverse weld, aligning the middle of the two steel pipes for welding:

[0053] S31. The middle part of the two-way fluxing pipe is heated and melted and gradually contacts the side walls of the two steel pipes that are close to each other to form a radial weld;

[0054] S32. The two ends of the two-way fluxing pipe melt gradually, and the high thermal conductivity gas inside it gradually expands to push th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com