Flame retardant flexible composite color flake and preparation method thereof

A flame-retardant, composite diaphragm technology, which is applied in the field of construction and decorative materials, can solve the problems of high brittleness, no flame retardancy, and low fire-resistant grade of color flakes or rock flakes, and achieve fast drying speed and high bending strength. Good, the effect of improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

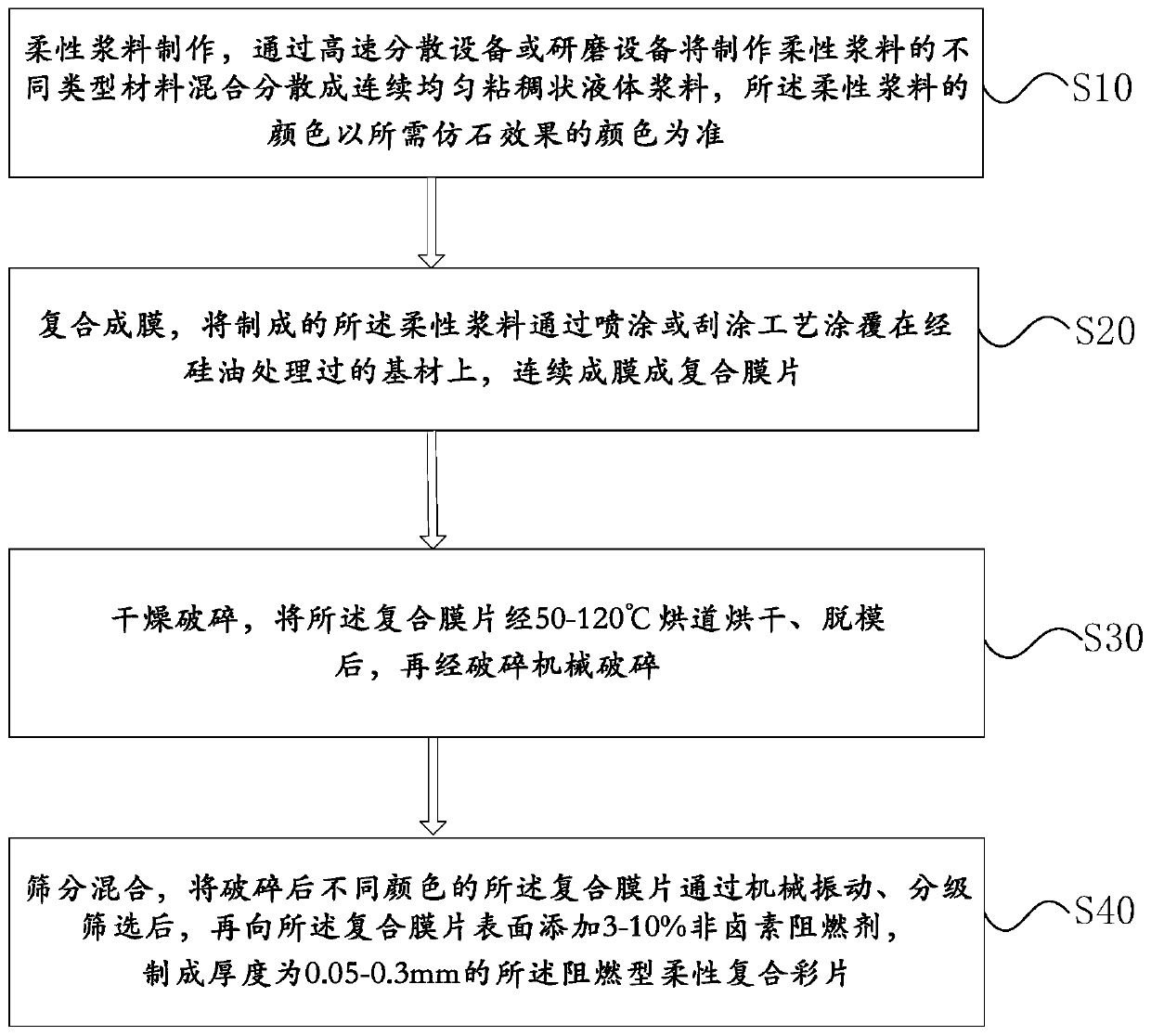

[0054] Another aspect of the present invention, such as figure 1 As shown, a method for preparing the above-mentioned flame-retardant flexible composite color sheet is provided, comprising the following steps:

[0055] S10. Production of flexible slurry. Mix and disperse different types of materials for making flexible slurry into continuous uniform viscous liquid slurry through high-speed dispersing equipment or grinding equipment. The color of the flexible slurry is the color of the required stone-like effect prevail;

[0056] S20, forming a compound film, coating the prepared flexible slurry on the substrate treated with silicone oil through a spraying or scraping process, and continuously forming a film into a composite film;

[0057] S30, drying and crushing, the composite diaphragm is dried in a 50-120°C oven, demoulded, and then mechanically crushed by a crusher;

[0058] S40, sieving and mixing, after the crushed composite diaphragms of different colors are mechanica...

Embodiment 1

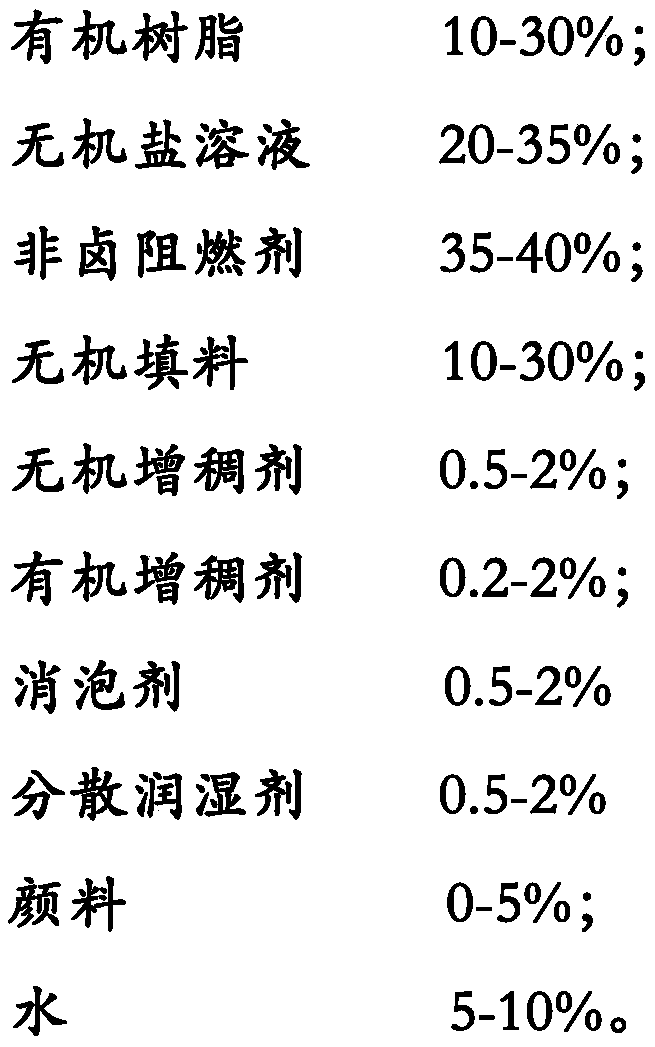

[0063] In this embodiment, the weight content of each component of the flexible slurry is:

[0064]

[0065] The production process of the flame-retardant flexible composite color film of the present embodiment is as follows:

[0066] First, prepare colored flexible slurry, and the color of the slurry is subject to the color of the required stone-like effect; secondly, after the colored slurry is prepared, it is scraped or sprayed on the silicone oil-treated base paper or special Teflon-based fabric; then dried with hot air in an oven at 50-120°C, crushed and sieved after demoulding; finally add 5% non-halogen flame retardant and mix to prepare a flame retardant with a thickness of 0.05-0.3mm Combustible flexible composite color film.

Embodiment 2

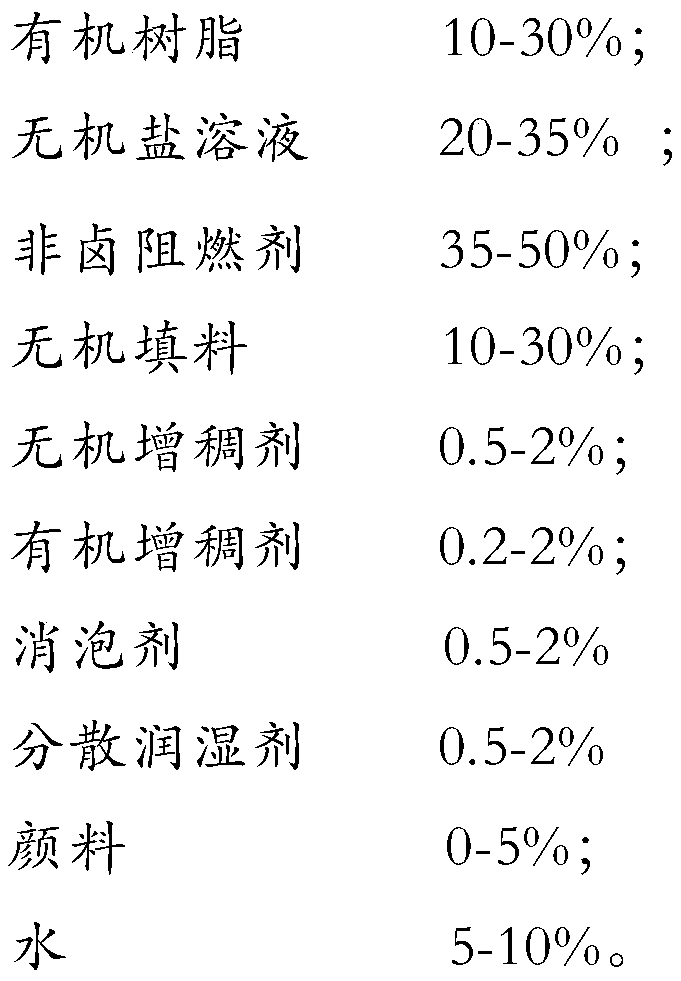

[0068] In this embodiment, the weight content of each component of the flexible slurry is:

[0069]

[0070] The production process of the flame-retardant flexible composite color film of the present embodiment is as follows:

[0071] First, prepare colored flexible slurry, and the color of the slurry is subject to the color of the required stone-like effect; secondly, after the colored slurry is prepared, it is scraped or sprayed on the silicone oil-treated base paper or special Teflon-based fabric; then dried with hot air in an oven at 50-120°C, crushed and sieved after demoulding; finally, 8% non-halogen flame retardant is added and mixed to obtain a flame retardant with a thickness of 0.05-0.3mm Combustible flexible composite color film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com