Bonded type coating board for outer wall and manufacturing method thereof

A technology for exterior wall coatings and production methods, which is applied in the field of coating boards, can solve problems such as high construction technical requirements, fragility and cracking, and heavy labor, and achieve high-end luxury decoration effects, not easy to break and crack, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

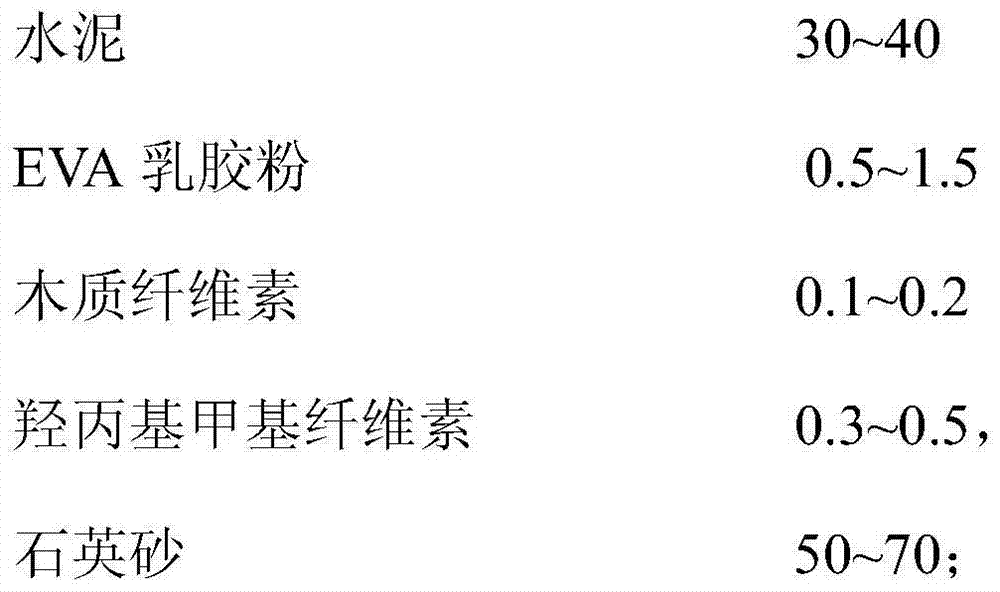

[0053] A paste-type exterior wall paint board, including a template and a paint layer on the surface of the film board; the thickness of the film board is 3mm, and the thickness is 120g / m 2 The glass fiber grid cloth of specifications and the filler filled in the glass fiber grid cloth are composed of the following composition and weight parts:

[0054] (1) Group A:

[0055] Cement 35, EVA latex powder 1.0, lignocellulose 0.1, hydroxypropyl methylcellulose 0.4; 1.0mm quartz sand 65;

[0056] (2) Part B: Acrylic waterproof emulsion

[0057] The weight ratio of the two components A and B is 10:1.0;

[0058] The paint layer has a thickness of 0.2 mm and is formed by an elastic paint and the paint coated on its outer surface.

[0059] The production method is as follows:

[0060] 1) Mix the two components of A and B, then add 15% by weight of water, stir well, and then flatten and fill the glass fiber grid to make a template;

[0061] 2) Curing and drying for 72 hours, keeping the temperature ...

Embodiment 2

[0067] A sticky exterior wall paint board, including a film board and a paint layer on the surface of the film board; the thickness of the film board is 3mm, and the thickness is 160g / m 2 The glass fiber mesh cloth of specifications and the filler filled in the glass fiber mesh cloth are composed of the following composition and weight:

[0068] (1) Group A:

[0069] Cement 35, EVA latex powder 1.0, lignocellulose 0.15, hydroxypropyl methylcellulose 0.3; 1.5mm quartz sand 60;

[0070] (2) Part B: Acrylic waterproof emulsion

[0071] The weight ratio of the two components A and B is 10:1.2;

[0072] The paint layer has a thickness of 0.3 mm and is formed by an elastic paint and the paint coated on its outer surface.

[0073] The production method is as follows:

[0074] 1) Mix the two components of A and B, then add 20% by weight of water, stir well, and then flatten and fill the glass fiber grid to make a template;

[0075] 2) Curing and drying for 85 hours, maintaining a temperature of 40...

Embodiment 3

[0081] A paste-type exterior wall paint board, comprising a template and a coating layer on the surface of the template; the thickness of the template is 5mm, and the thickness is 180g / m 2 The glass fiber grid cloth of specifications and the filler filled in the glass fiber grid cloth are composed of the following composition and weight parts:

[0082] (1) Component A:

[0083] Cement 40, EVA latex powder 1.5, lignocellulose 0.2, hydroxypropyl methylcellulose 0.5; 0.5mm quartz sand 55;

[0084] (2) Part B: Acrylic waterproof emulsion

[0085] The weight ratio of A and B components is 10:1.5;

[0086] The paint layer has a thickness of 0.5 mm and is formed by sand wall-like paint and paint coated on its outer surface.

[0087] The production method is as follows:

[0088] 1) Mix the two components of A and B, then add 25% by weight of water, stir well, and then flatten and fill the glass fiber grid to make a template;

[0089] 2) Curing and drying for 96 hours, maintaining a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com