Hydraulic engineering thermal insulation material and preparation method thereof

A thermal insulation material and water conservancy engineering technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of consideration, no environmental protection and cost, and achieve the effect of reducing dry lines, saving costs, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

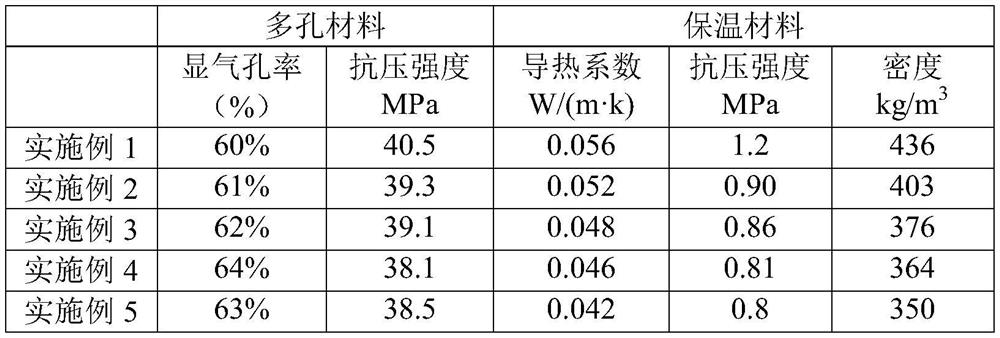

Examples

Embodiment 1

[0031] A thermal insulation material for water conservancy projects, made of the following raw materials in parts by weight: 20 parts of slag cement, 10 parts of mica powder, 5 parts of porous material, 3 parts of vitrified microbeads, 0.6 parts of foaming agent, and 1 part of polyaluminum chloride 2 parts, 2 parts of potassium polyacrylate and 18 parts of water.

[0032] The foaming agent is a mixture of hoof keratin solution, sodium lauryl sulfate, tea saponin and sodium carboxymethyl cellulose in a weight ratio of 1:0.5:0.1:0.1.

[0033] The preparation method of the hoof keratin liquid is as follows: disperse the hoof horn powder in 5 times the weight of 2wt% lye, bathe in 90° C. water for 8-10 hours, and then filter to remove the filter residue to obtain the product.

[0034] The vitrified microbeads used are obtained by mixing vitrified microbeads with a particle size of 200-300 μm and a particle size of 300-500 μm at a weight ratio of 1:1.

[0035] Wherein the porous m...

Embodiment 2

[0047] A thermal insulation material for water conservancy projects, made of the following raw materials in parts by weight: 22 parts of slag cement, 9 parts of mica powder, 6 parts of porous material, 2.5 parts of vitrified microbeads, 0.7 parts of foaming agent, and 1.2 parts of polyaluminum chloride 1.5 parts of potassium polyacrylate and 20 parts of water.

[0048] The foaming agent is a mixture of hoof keratin solution, sodium lauryl sulfate, tea saponin and sodium carboxymethyl cellulose in a weight ratio of 1:0.6:0.1:0.1.

[0049] The preparation method of the hoof keratin liquid is as follows: disperse the hoof horn powder in 6 times the weight of 3wt% lye, bathe in 90°C water for 8-10 hours, and then filter to remove the filter residue to obtain the product.

[0050] The vitrified microbeads used are obtained by mixing vitrified microbeads with a particle size of 200-300 μm and a particle size of 300-500 μm at a weight ratio of 1:1.

[0051] Wherein the porous materi...

Embodiment 3

[0063] A thermal insulation material for water conservancy projects, made of the following raw materials in parts by weight: 25 parts of slag cement, 8 parts of mica powder, 8 parts of porous materials, 2.8 parts of vitrified microbeads, 0.8 parts of foaming agent, and 1.5 parts of polyaluminum chloride 1.5 parts of potassium polyacrylate and 22 parts of water.

[0064] The foaming agent is formed by mixing hoof keratin liquid, sodium lauryl sulfate, tea saponin and sodium carboxymethyl cellulose in a weight ratio of 1:0.7:0.15:0.15.

[0065] The preparation method of the hoof keratin liquid is as follows: disperse the hoof horn powder in 6 times the weight of 4wt% lye, bathe in 90°C water for 8-10 hours, and then filter to remove the filter residue to obtain the product.

[0066] The vitrified microbeads used are obtained by mixing vitrified microbeads with a particle size of 200-300 μm and a particle size of 300-500 μm at a weight ratio of 1:1.

[0067] Wherein the porous m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com