Lightweight cellular concrete composite large plate with functions of decoration, bearing and heat preservation, and production method thereof

A technology for decorating concrete and concrete, which is applied in thermal insulation, manufacturing tools, building components, etc., can solve the problems of complicated construction procedures, loss of thermal insulation effect, labor and time consuming, etc. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

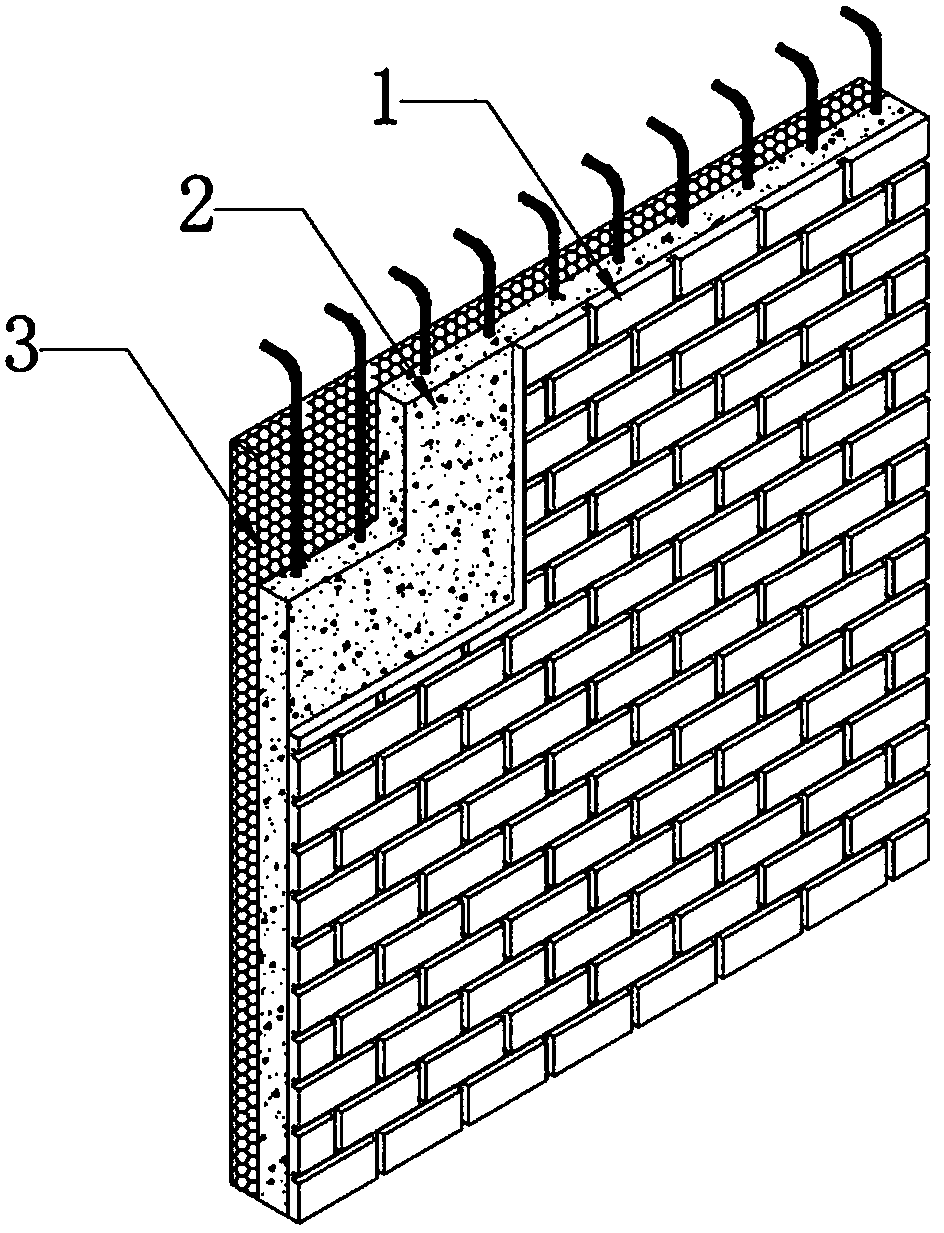

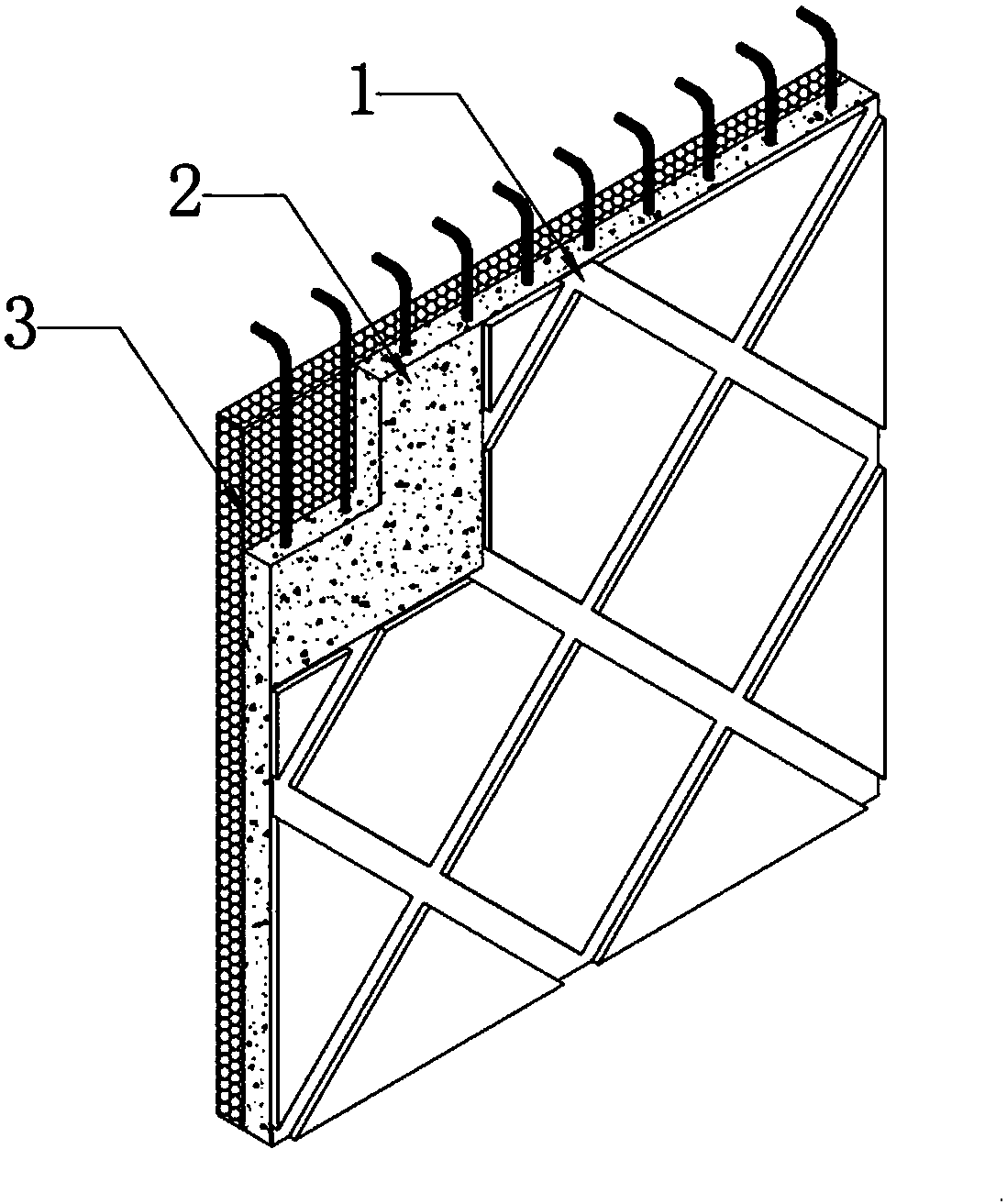

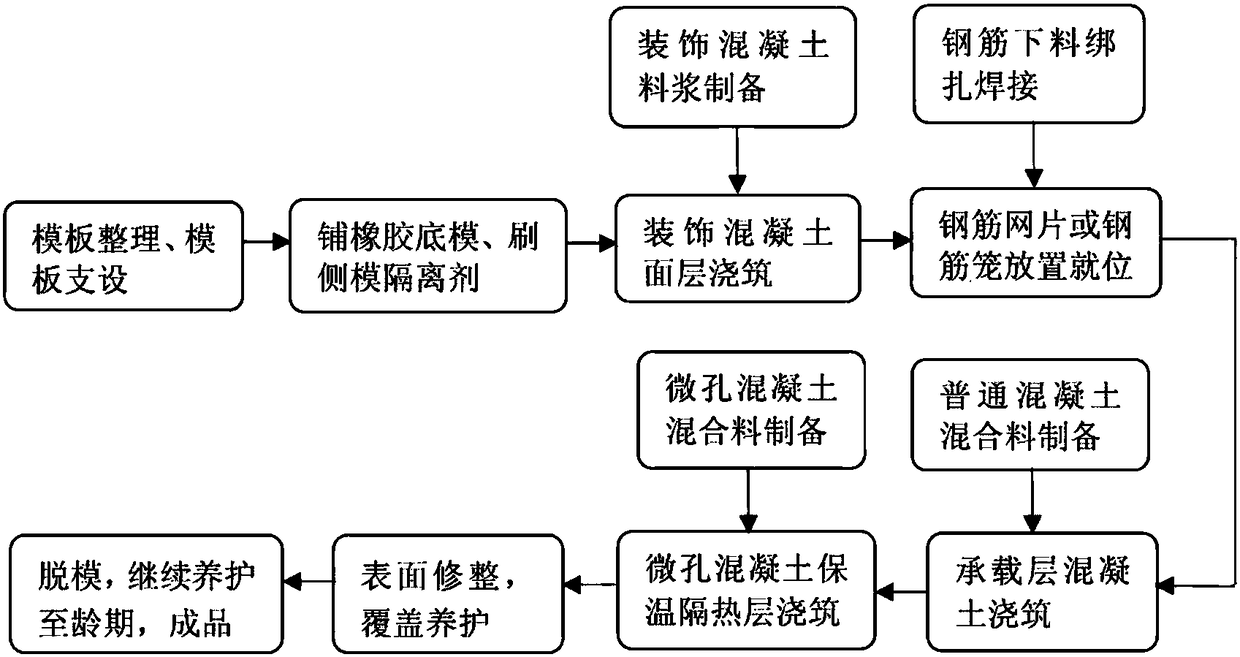

[0048] Such as Figure 1a and 1b As shown, the present invention provides a light-weight microporous concrete composite slab with functions of decoration, bearing and heat preservation on the one hand, and the composite slab (which can be an exterior wall) is sequentially provided with a decorative concrete surface layer 1, Reinforced ordinary concrete bearing layer 2 and microporous concrete insulation layer 3.

[0049] Wherein, the decorative texture on the surface of the decorative concrete surface layer 1 can be split stone, mushroom stone, marble texture, bamboo imitation, wood texture or appearance texture imitating clear water brick wall. The thickness of the decorative concrete surface layer 1 is 2-5mm. The composition of the raw materials of the decorative concrete surface layer 1 is as follows according to the weight ratio per cubic meter of concrete:

[0050] The particle size of 1.25-5mm is 45-60%, and the particle size of 1.25mm or less is 40-55%.

[0051] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com