Multifunctional novel decoration plate and manufacturing technique thereof

A production process and technology for decorative panels, which are applied in lamination devices, other household appliances, lamination, etc., can solve the problems of dark surface of fire-resistant decorative panels, inability to apply high-grade decorative coatings, rough and unequal surfaces, and improve the effect of decoration and beautification. , bright pictures and text, good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

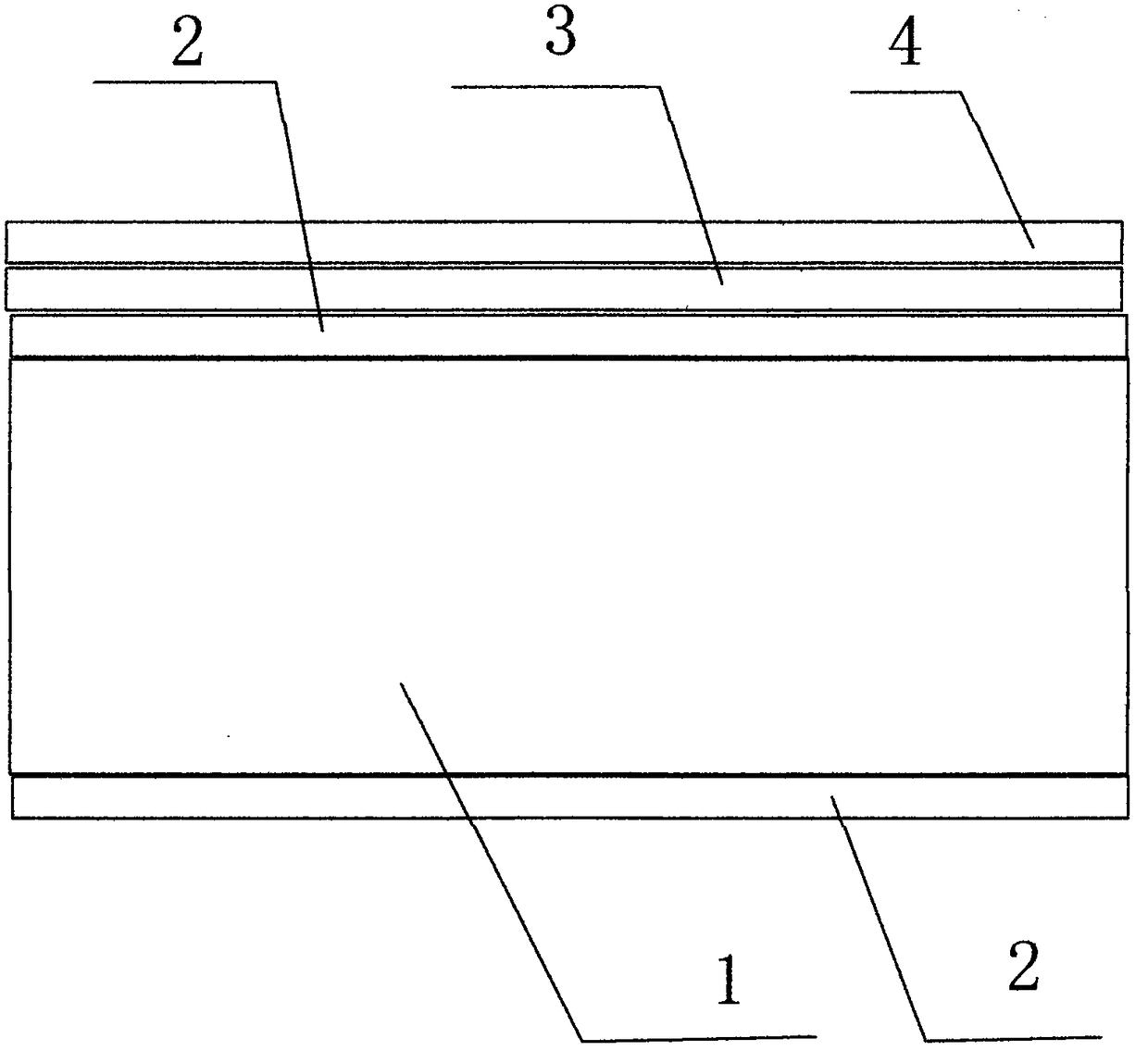

[0012] refer to figure 1 , according to one embodiment of the present invention, a new multifunctional decorative board and its manufacturing process, including a substrate 1, a melamine resin layer 2, a decorative layer 3 and a fireproof coating layer 4, the melamine resin 2 is heated at a temperature of 210 degrees Celsius, The pressure is 6 tons / square meter and pressed onto the upper and lower surfaces of the substrate layer 1, the decorative layer 3 is pasted on the melamine resin layer 2 on the surface of the substrate layer 1, and the outer surface of the decorative layer 3 is Coated with fire-resistant paint layer 4. The fireproof coating layer 4 is a paint layer or other coatings. The decorative layer 3 is a pattern layer composed of ink printing or ink printing plus vacuum aluminum plating. The decorative layer 3 can also use a printed film to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com