Sectional-type thermal power tunnel antiskid strip

A segmented, thermal pipeline technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as increased construction difficulty, waste, and increased structural material consumption, so as to reduce self-weight and structural material consumption, and reduce construction difficulty. The effect of improving the anti-skid ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

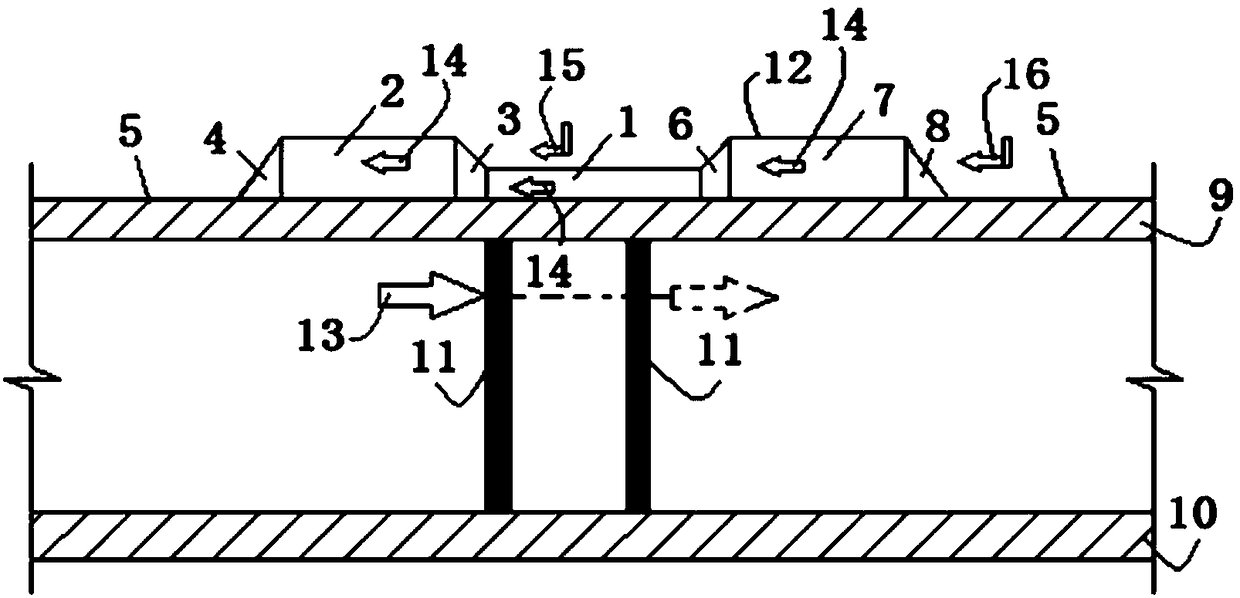

[0016] Below with the accompanying drawings ( figure 1 ) to illustrate the present invention.

[0017] figure 1 It is a structural schematic diagram of a segmented thermal tunnel anti-sliding strip implementing the present invention. like figure 1 As shown, a segmented thermal tunnel anti-slip strip includes an anti-slip structural unit 12 arranged on the outer peripheral surface 5 of the thermal tunnel structure. The anti-slip structural unit 12 has a segmented structure distributed along the axial direction. Concave-convex structures are formed between segments of the segmented structure. The anti-skid structural unit 12 includes a first section 2, a second section 1 and a third section 7 distributed in sequence from left to right, the second section 1 is a low platform section, and the first section 2 and the third section Section 7 is a high platform section. A second transition surface 3 is formed between the first section 2 and the second section 1, and the slope an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com