Double-stirring double-cutting sewage pump

A sewage pump and double stirring technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of poor sewage discharge capacity and easy blockage, and achieve the effect of avoiding clogging and improving sewage discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

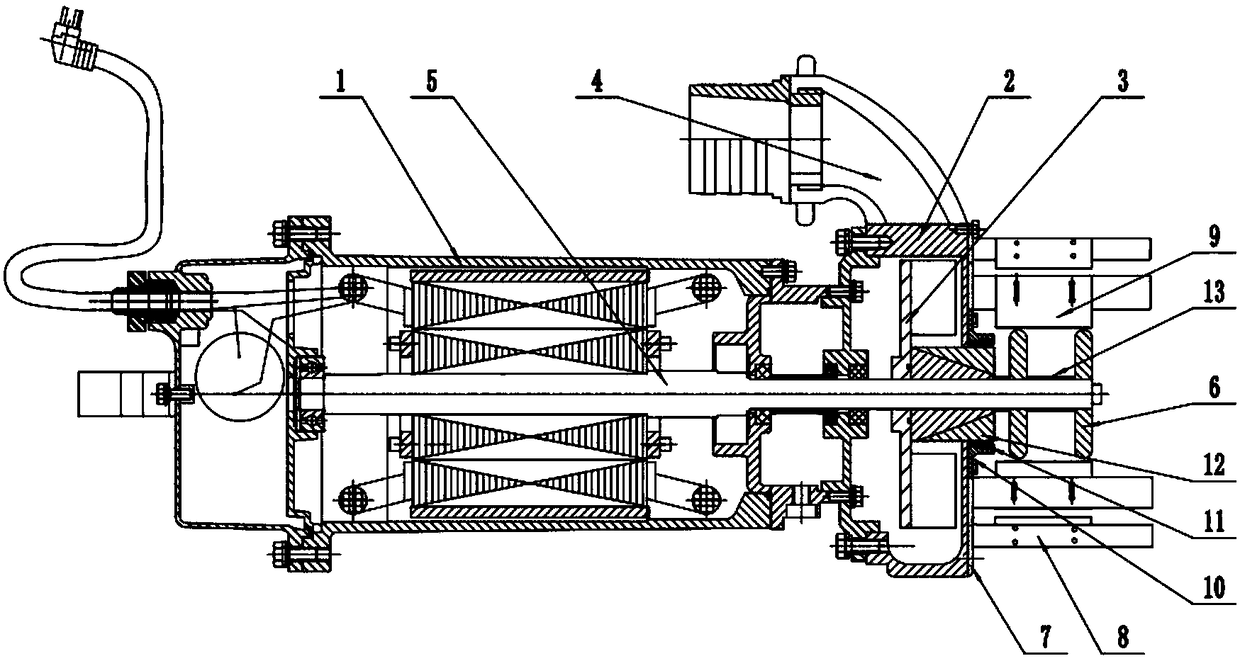

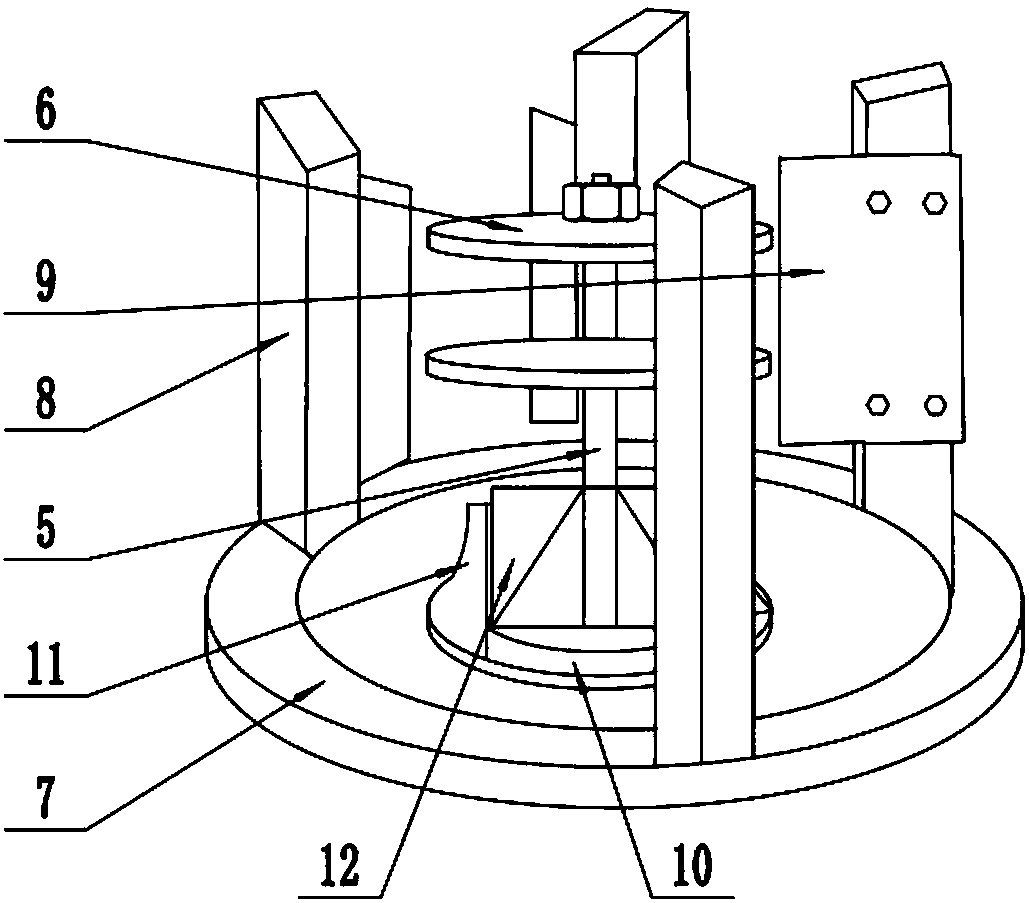

[0021] like figure 1 and 2 As shown, Embodiment 1 provides a double-stirring double-cutting sewage pump, which includes a motor 1, a pump body 2, an impeller 3, a connecting pipe 4, a first stirring and cutting part and a second stirring and cutting part, and the pump body 2 is cylindrical Hollow shell, the right end of the pump body 2 is provided with a water inlet (not shown in the drawings), the side of the cylinder of the pump body 2 is provided with a water outlet (not shown in the drawings), and the motor 1 is fixed on the left end of the pump body 2 The motor 1 provides the kinetic energy for the sewage pump to do work. The motor shaft 5 of the motor 1 runs through the pump body 2 and the free end of the motor shaft 5 is exposed at the water inlet of the pump body 2. The exposed part of the motor shaft 5 is used to install other parts. The impeller 3 Set in the pump body 2, and the impeller 3 is socketed and fixed on the motor shaft 5. The impeller 3 and the motor shaf...

Embodiment 2

[0024] Embodiment 2 provides a double-agitation and double-cutting sewage pump, whose structure is basically the same as that of the double-agitation and double-cutting sewage pump provided in embodiment 1, and only the differences will be described below.

[0025] In this embodiment, the first movable knife 6 is a circular plate, and when the circular plate-shaped first movable knife 6 is working in the sewage pump, its circular plane can also prevent sundries in the sewage from directly entering the water inlet. , to avoid sundries hitting the impeller 3, the arc edge of the circular plate is the cutting edge of the first moving knife, the axis of the first moving knife 6 coincides with the axis of the motor shaft 5, and there are two first moving knives 6, both of which are set On the right side of the motor shaft 5 and the two are arranged at intervals along the axial direction of the motor shaft 5, a shaft sleeve 13 is arranged between the two first moving knives 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com