Automatic aperture adjusting structure and adjusting method

A technology of automatic adjustment and aperture, applied in aperture, optics, camera and other directions, can solve the problems of high motor cost and high requirements for motor use environment, and achieve the effect of low cost, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

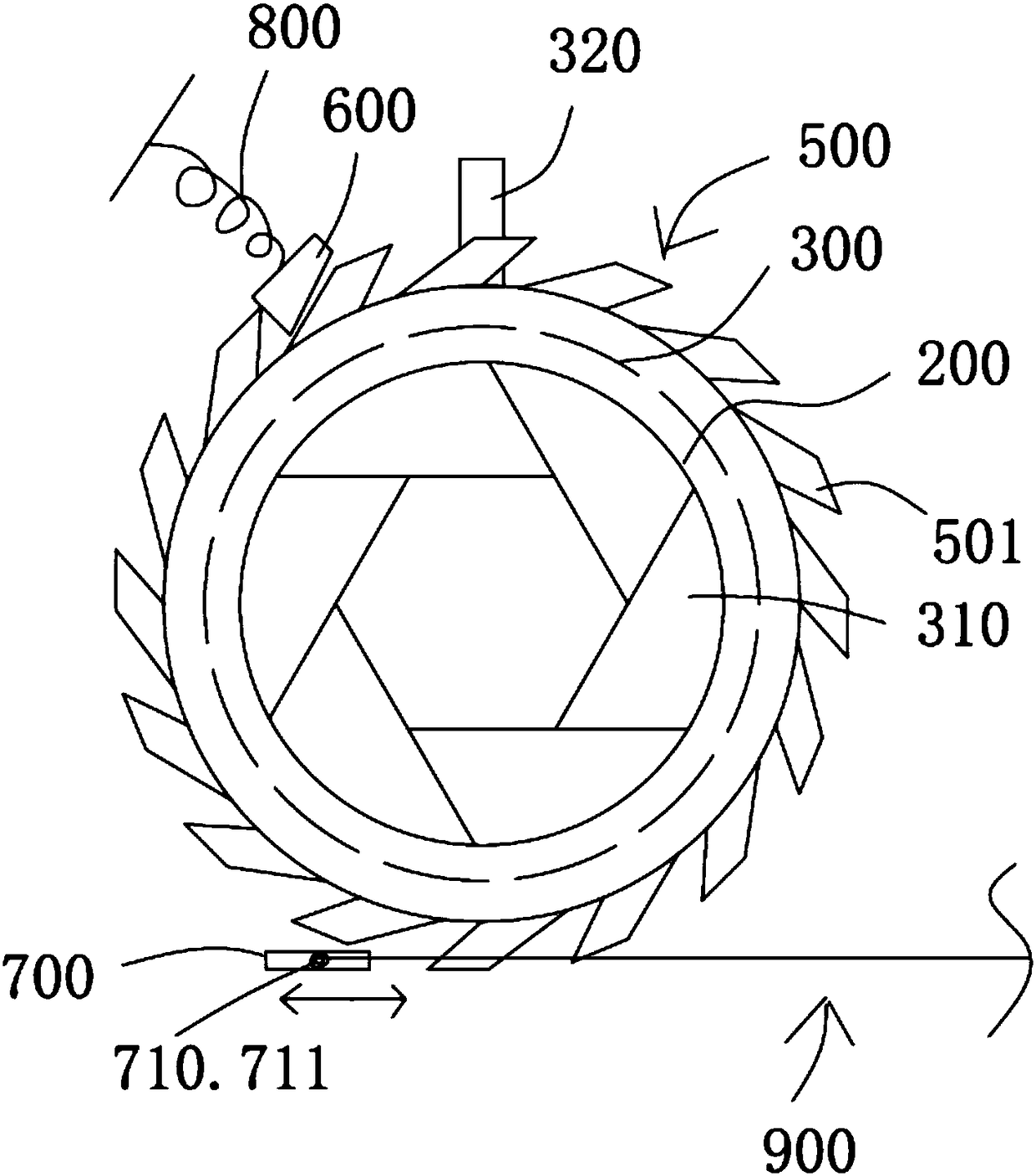

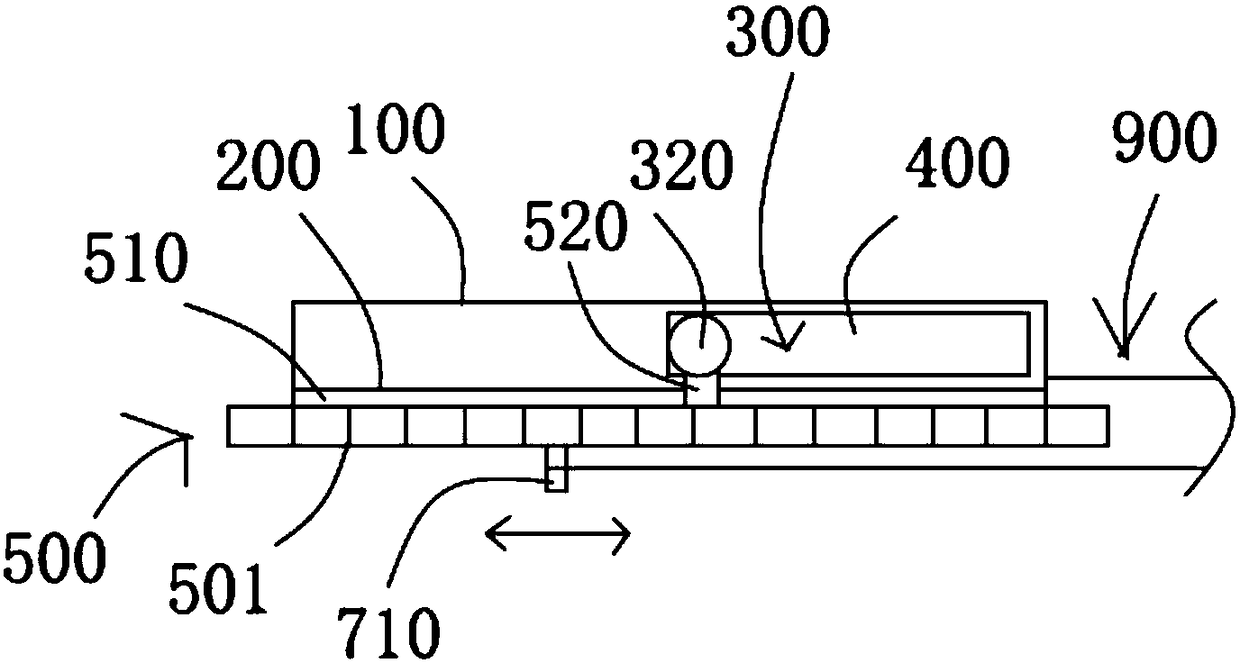

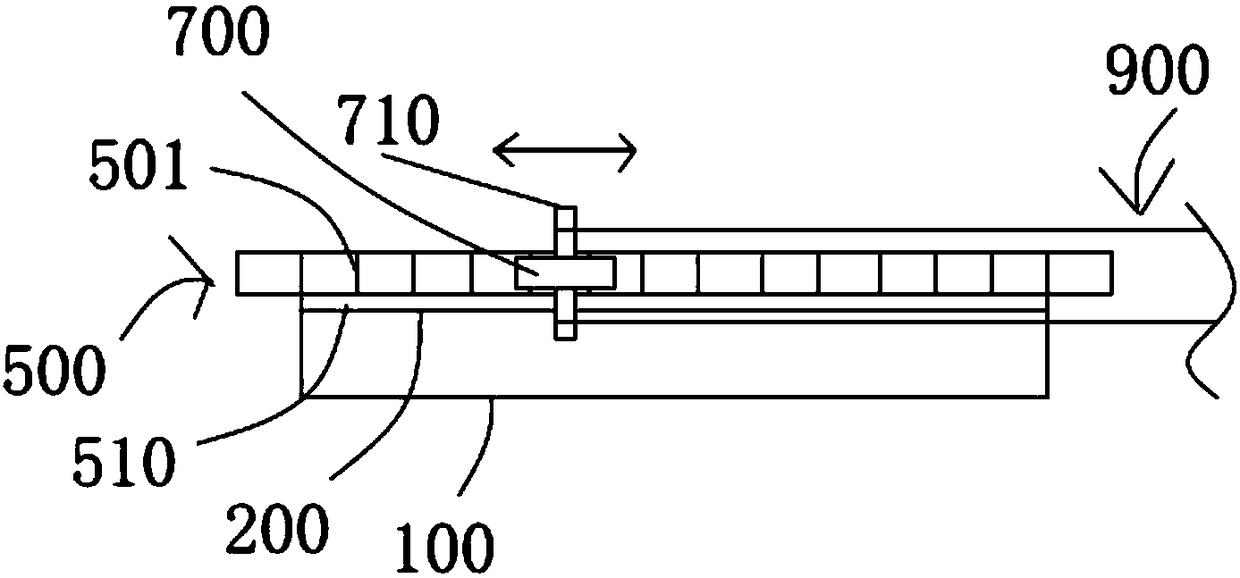

[0031] see Figure 1 to Figure 3 An automatic aperture adjustment structure is shown, including an aperture base plate 100, an aperture back plate 200 used in conjunction with the aperture base plate 100, and an aperture paddle 300 arranged between the aperture base plate 100 and the aperture back plate 200 and installed on the aperture base plate 100 . The aperture paddle 300 is provided with a plurality of blades 310 , the aperture paddle 300 has a driving part 320 connected to the driving assembly, and the aperture bottom plate 100 or the aperture backboard 200 is provided with a limiting portion 400 to limit the movable stroke of the driving portion 320 . The limiting part 400 in this embodiment is an arc-shaped groove with a central angle of 90°, the driving part 320 is a driving rod, and the positions of the two ends of the driving part 320 in the arc-shaped groove are respectively two limit positions. The above-mentioned technology is the same as the aperture principle...

Embodiment 2

[0038] see Figure 4 As shown, the general structure of this embodiment is the same as that of Embodiment 1, the difference is that the teeth 501a of the ratchet ring 500a are helical teeth, the direction of movement of the driving pawl 700a is parallel to the direction of inclination of the helical tooth structure, and the driving pawl 700a One end facing the forward rotation of the ratchet ring 500a is provided with a reset compression part 710a. The second memory alloy element 900a includes a memory alloy wire that drives the movement of the ratchet 700a. The reset compression part 710a includes a compression spring 711a and a compression spring connected with the compression spring. Tight ball 712a.

[0039]The principle of braking and gear adjustment of the ratchet ring 500a in this embodiment is the same as that of Embodiment 1, the difference lies in the way that the driving pawl 700a cooperates with the second memory alloy element 900a to drive the ratchet ring 500a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com