Crystal Growth Furnace

A technology of crystal growth furnace and reaction chamber, which is applied in the direction of crystal growth, single crystal growth, and from chemically reactive gases. It can solve the problems of high background carrier concentration, adverse effects, and insufficient purity of the reaction chamber. Guaranteed high purity, reduced background carrier concentration, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The purpose of the present invention is to design a high-temperature silicon carbide crystal growth device without graphite felt, which not only improves the cleanliness of the system, reduces the background carrier concentration of the epitaxial wafer, but also meets the needs of high-temperature heating of silicon carbide, thereby obtaining High quality silicon carbide epitaxial wafers.

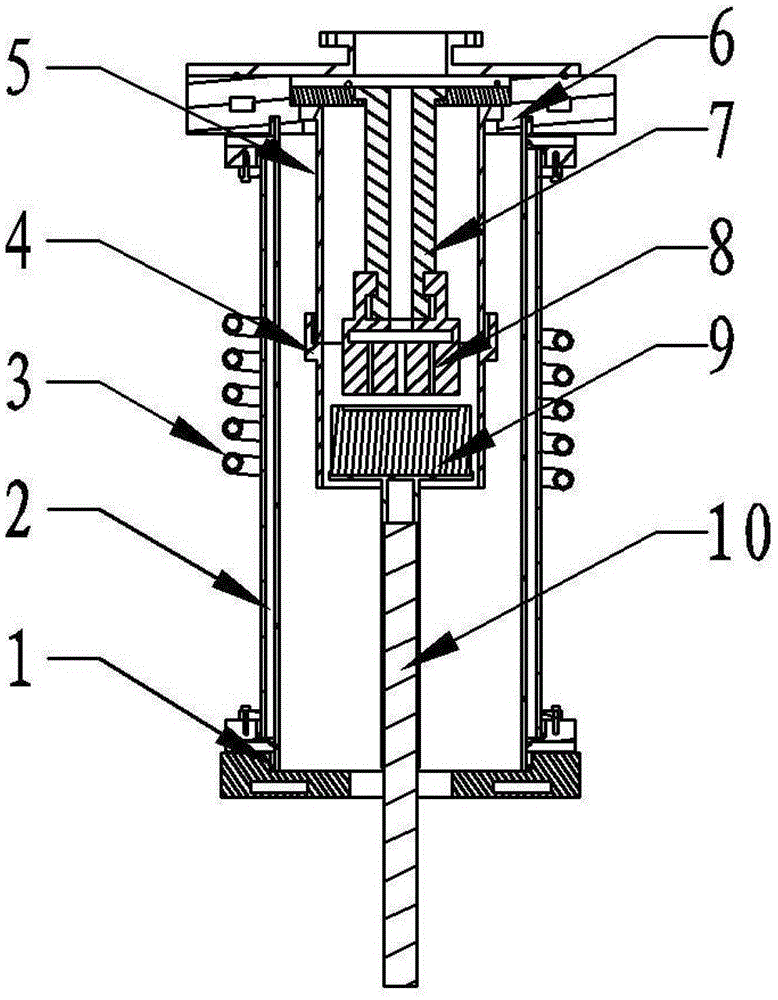

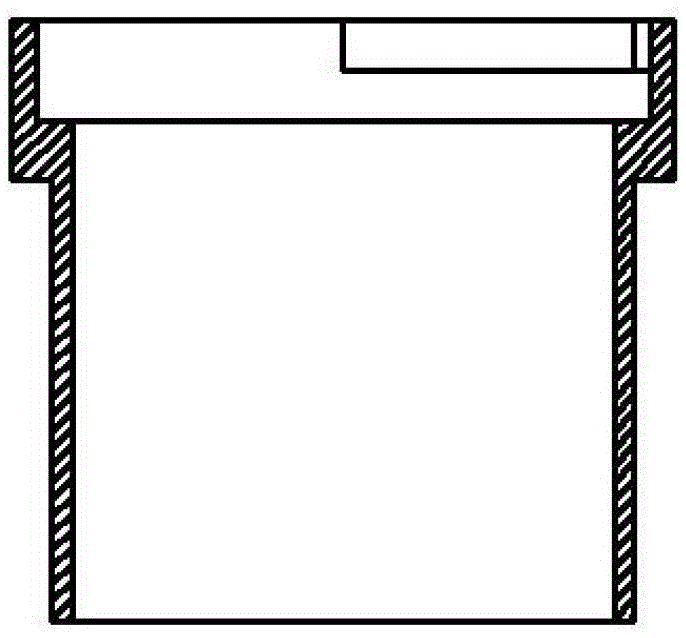

[0024] Such as figure 1 As shown, the crystal growth furnace provided by the present invention includes: a reaction chamber and a heating device, the reaction chamber includes a first thermal wall 5 and a second thermal wall 4, and the first thermal wall 5 and the second thermal wall 4 are detachably connected, and the first thermal wall 5 and the second thermal wall 4 enclose the reaction space of the crystal, the material of the second thermal wall 4 is graphite, and the heating device 3 cooperates with the second thermal The wall 4 is arranged to heat it; the material of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com