Engine piston having a notched top land

A technology of pistons and lands, applied to engine components, machines/engines, pistons, etc., can solve problems such as increased NOx and unburned hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

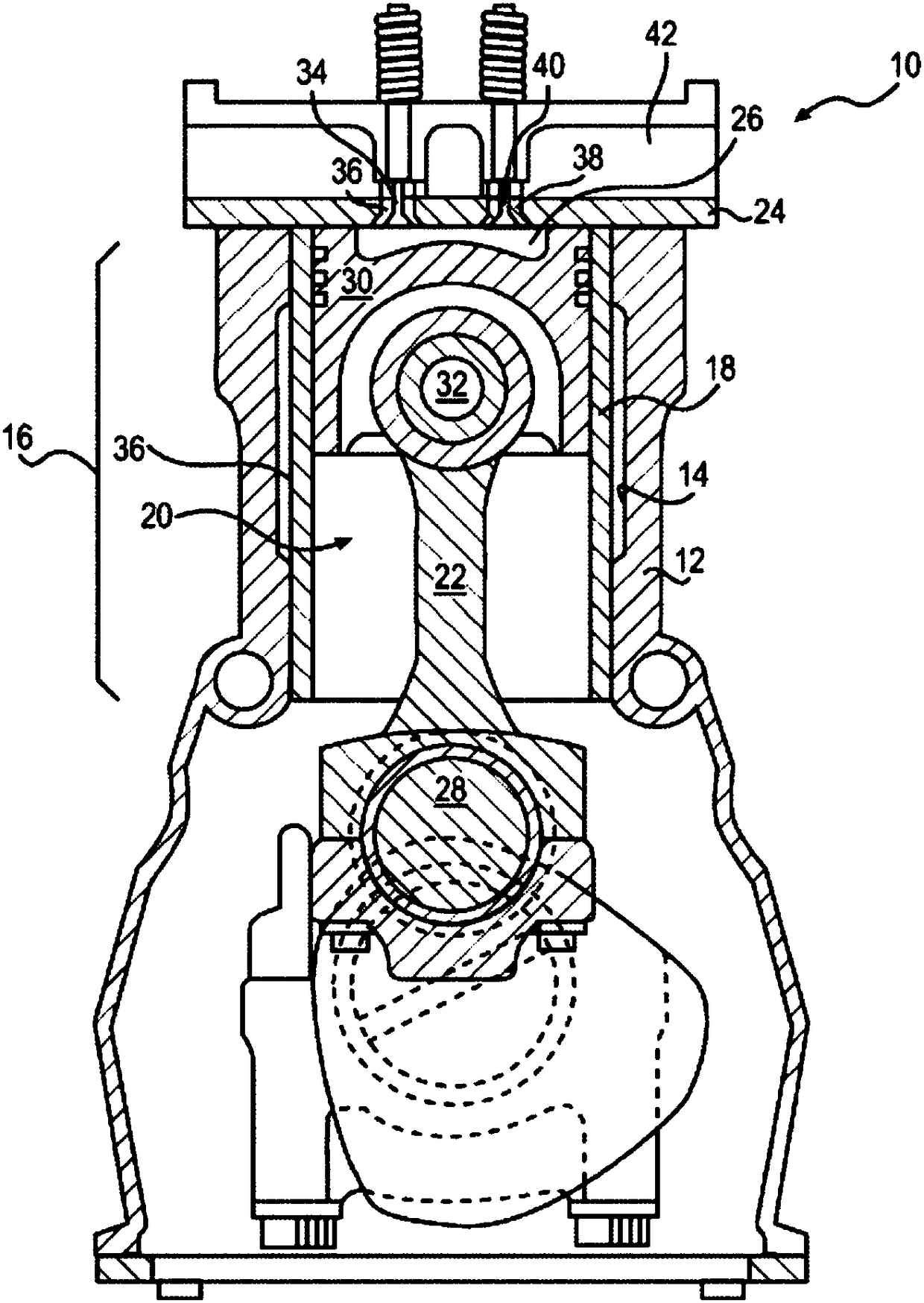

[0013] figure 1 An exemplary internal combustion engine 10 is illustrated. Engine 10 may be a four-stroke diesel engine. However, it is contemplated that engine 10 may be any other type of internal combustion engine, such as a dual-fuel powered two-stroke or four-stroke engine, a two-stroke diesel, gasoline or gaseous fuel powered engine, or a four-stroke gasoline engine. Engine 10 may include, among other things, an engine block 12 at least partially defining cylinders 14 and cylinder banks 16 . The cylinder bank 16 may include a cylinder liner 18 , a piston 20 slidably disposed within the cylinder liner 18 , and a connecting rod 22 . However, it is contemplated that cylinder bank 16 may include cylinders 14 without cylinder liners 18 , pistons 20 , which are slidably disposed within cylinders 14 , and connecting rods 22 . The engine 10 may include a cylinder head 24 that may be attached to the engine block 12 to close the ends of the cylinders 14 and / or cylinder liners 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com