Dimension compensation quantity determining method for bearing machining

A technology of bearing processing and compensation amount, which is applied in the field of bearing processing, to achieve the effects of easy operation, improving processing accuracy and processing efficiency, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

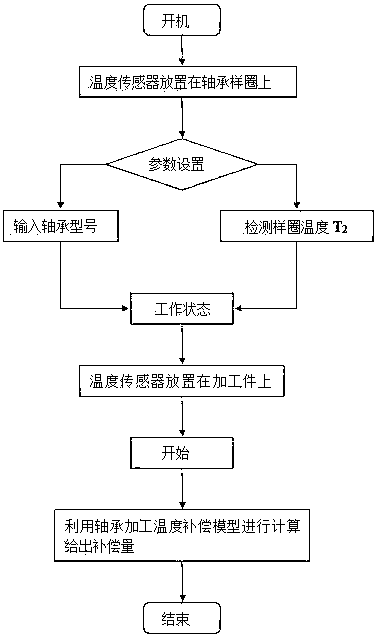

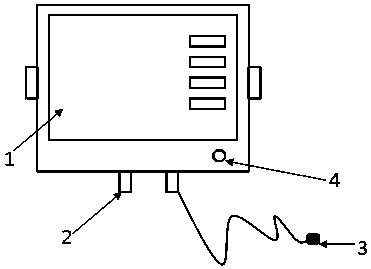

[0023] The method of determining the size compensation amount in bearing processing is to determine the type of workpiece to be processed and detect the temperature T of the standard part 2 and workpiece temperature T after processing 1 , select the pre-stored processing model and the corresponding processing parameters according to the workpiece model to be processed, and according to the standard part temperature T 2 , Workpiece temperature T after processing 1 and the corresponding processing parameters to assign values to the bearing processing model, so that the operator can know the size of the processed part when the temperature of the processed part is the same as that of the standard part. Calculate the workpiece size compensation ΔL.

[0024] Preferably, the processing model is a temperature compensation model; the processing parameters are the coefficient of thermal expansion α, the correction coefficient k and the diameter D of the workpiece.

[0025] Preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com