Robot joint variable stiffness actuator

A technology of robot joints and variable stiffness, applied in manipulators, manufacturing tools, joints, etc., can solve the problems of large volume of variable stiffness joints, low motor utilization rate, heavy weight, etc., and achieve the effect of small volume and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

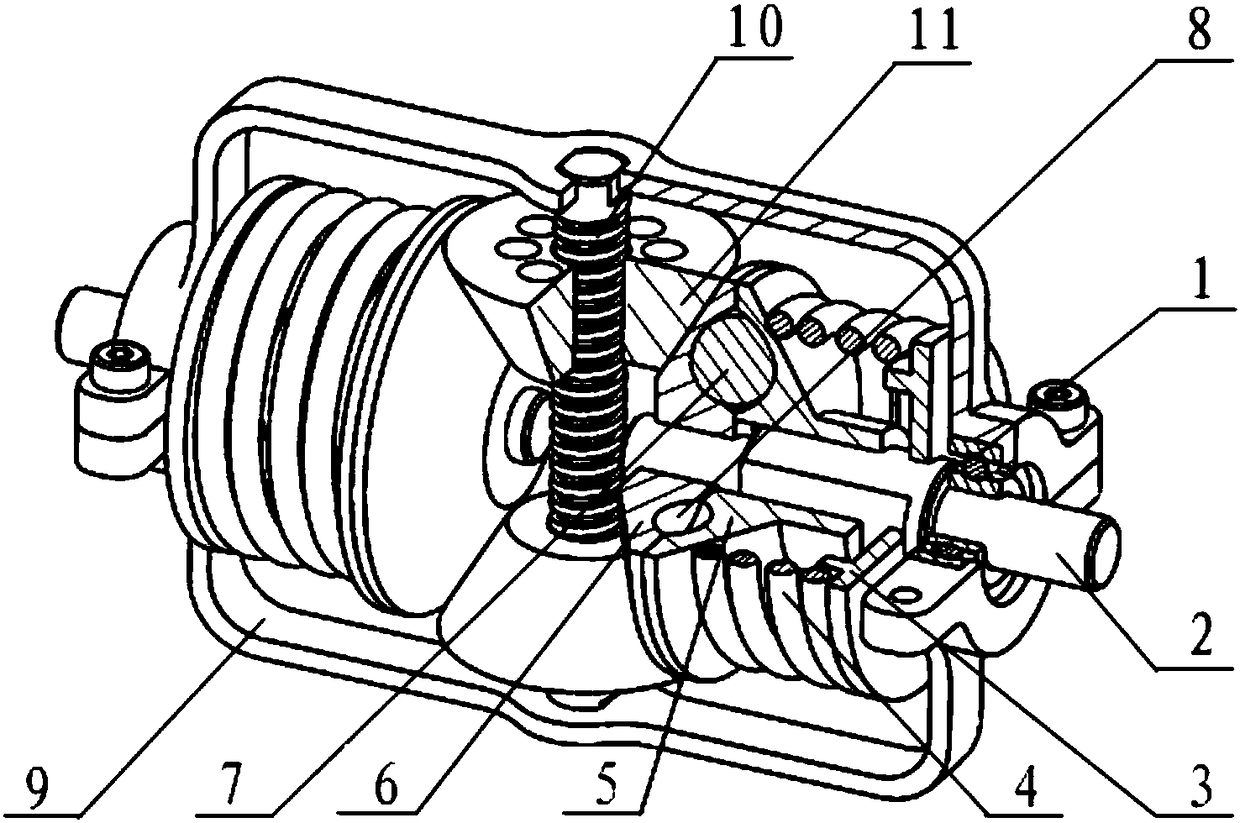

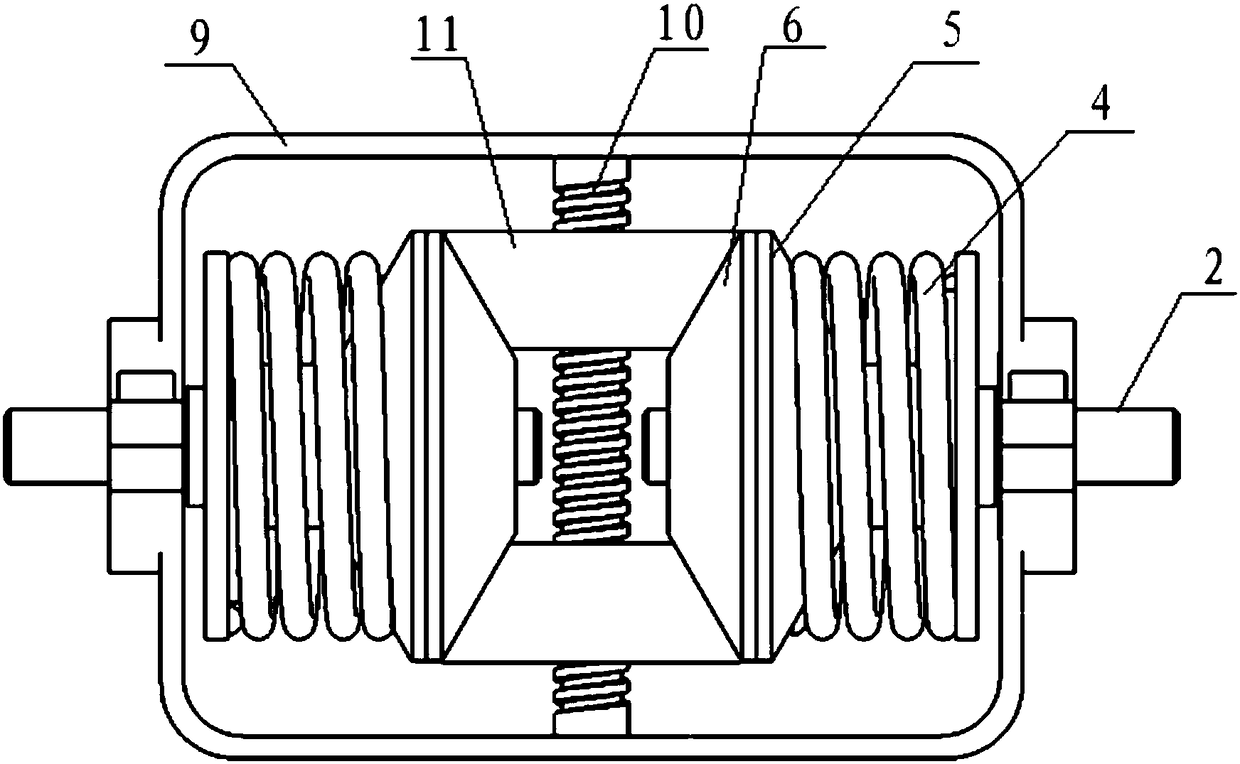

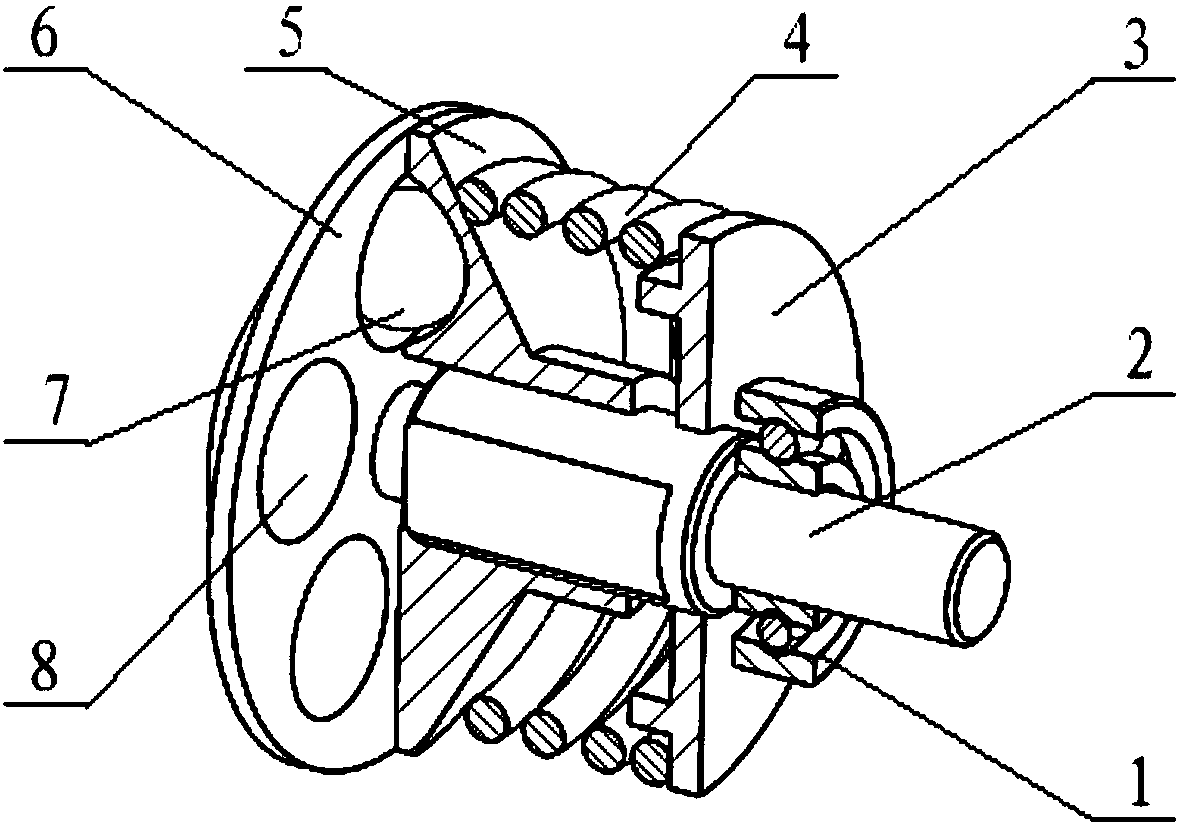

[0027] Such as Figure 1-2 , Figure 4 As shown, a robot joint variable stiffness actuator provided by the present invention includes a power output device and two sets of power input devices, wherein the power output device includes a power output frame 9, a lead screw 10 and a friction circular table 11, and the lead screw 10 is installed on On the power take-off frame 9, and be threadedly connected with two friction round tables 11, the small diameter ends of two friction round tables 11 are corresponding, two groups of power output devices are rotatably installed in the both sides of power take-off frame 9, and all with two The two friction round tables 11 are frictionally connected; by changing the relative steering of the two groups of powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com