Control device for hybrid power

A control device and hybrid technology, applied in power plants, hybrid vehicles, pneumatic power plants, etc., can solve the problems of high transmission cost, limited motor power, impact, etc., and achieve smooth and comfortable acceleration and deceleration without power. Loss and impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

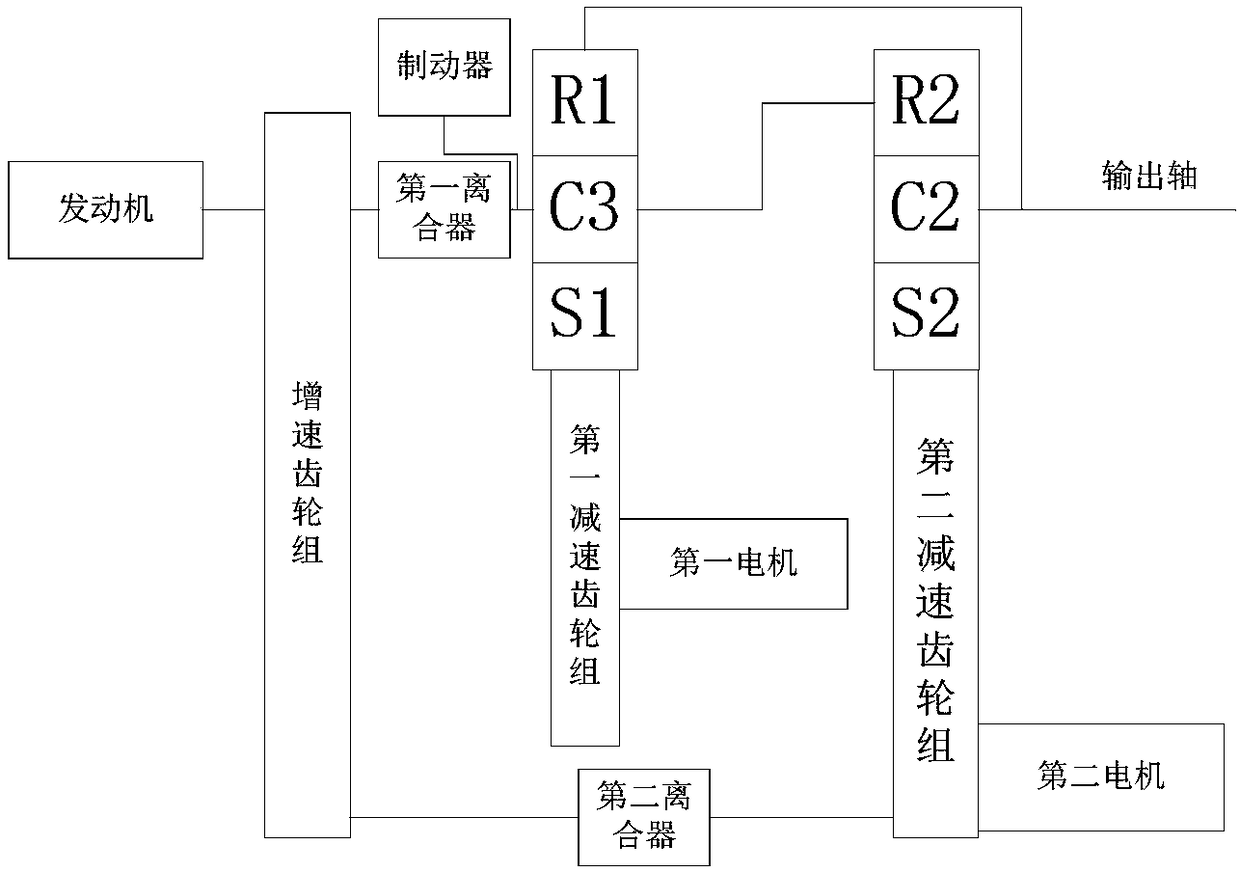

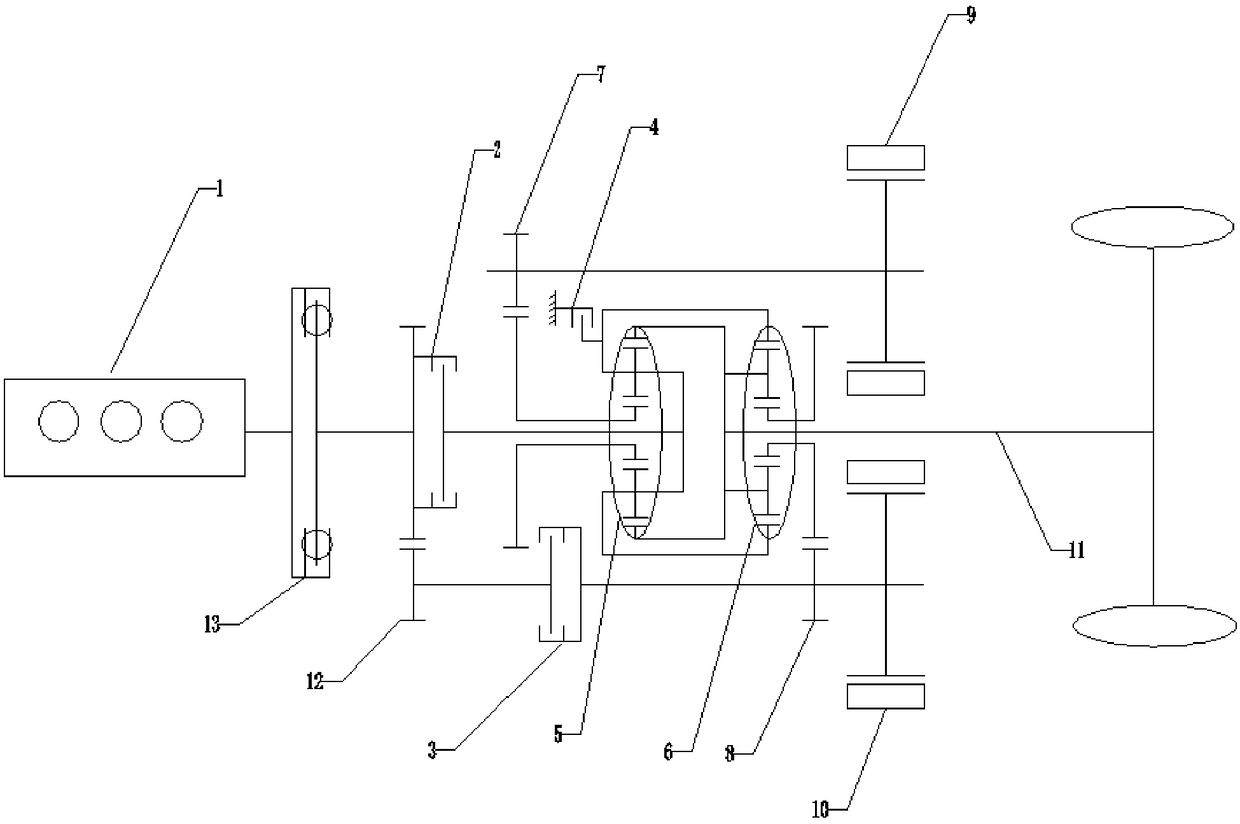

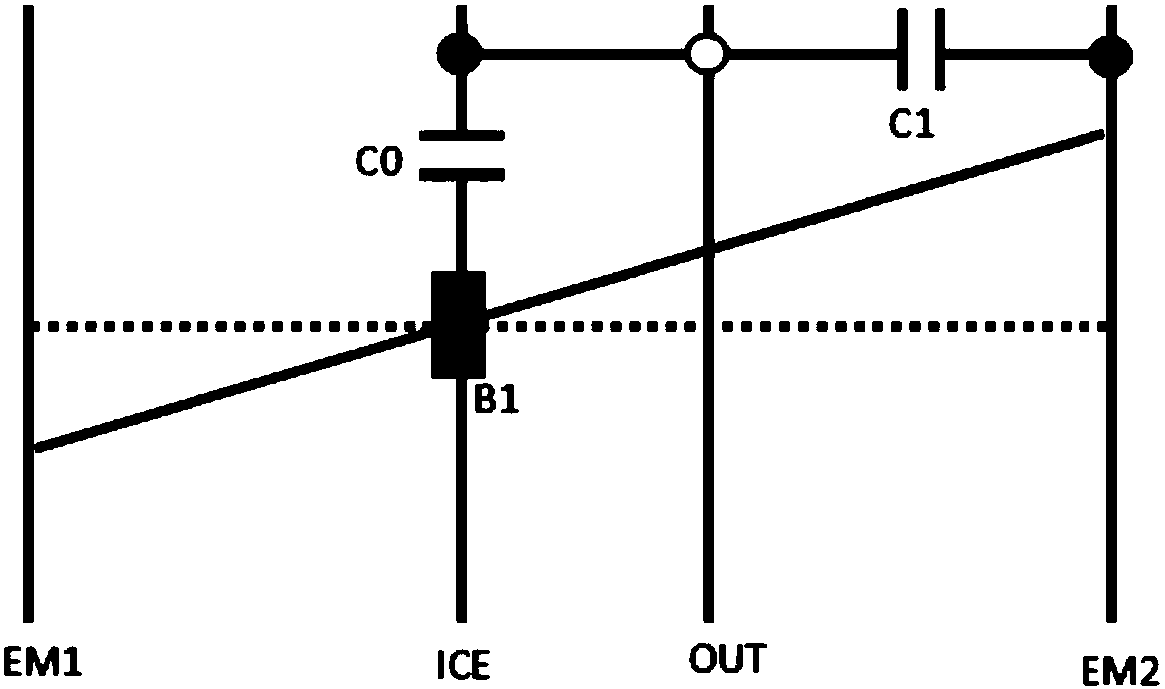

[0030] Please refer to Figure 1-Figure 6 , Embodiment 1 of the present invention is:

[0031] A hybrid control device, including an engine 1, a first clutch 2, a second clutch 3, a brake 4, a first planetary row 5, a second planetary row 6, a first reduction gear set 7, and a second reduction gear set 8 , the first motor 9, the second motor 10 and the output shaft 11, the engine, the first planetary row and the second planetary row are arranged in sequence, the engine is connected to the first planetary row through the first clutch, and the engine is connected to the first planetary row through the first The second clutch is connected with the second motor;

[0032] The first planetary row includes a first ring gear R1, a first planetary carrier C3 and a first sun gear S1, and the second planetary row includes a second ring gear R2, a second planetary carrier C2 and a second sun gear S2, The first ring gear is coaxially connected to the second planet carrier, the second pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com