Digital weighing sensor and sensor network

A weighing sensor and sensor technology, applied in the field of weighing system, can solve the problems of single working mode, increased complexity of weighing system process and working conditions, unable to adapt to intelligent switching of multiple configuration modes, etc., and achieve flexible working mode , the effect of various working modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

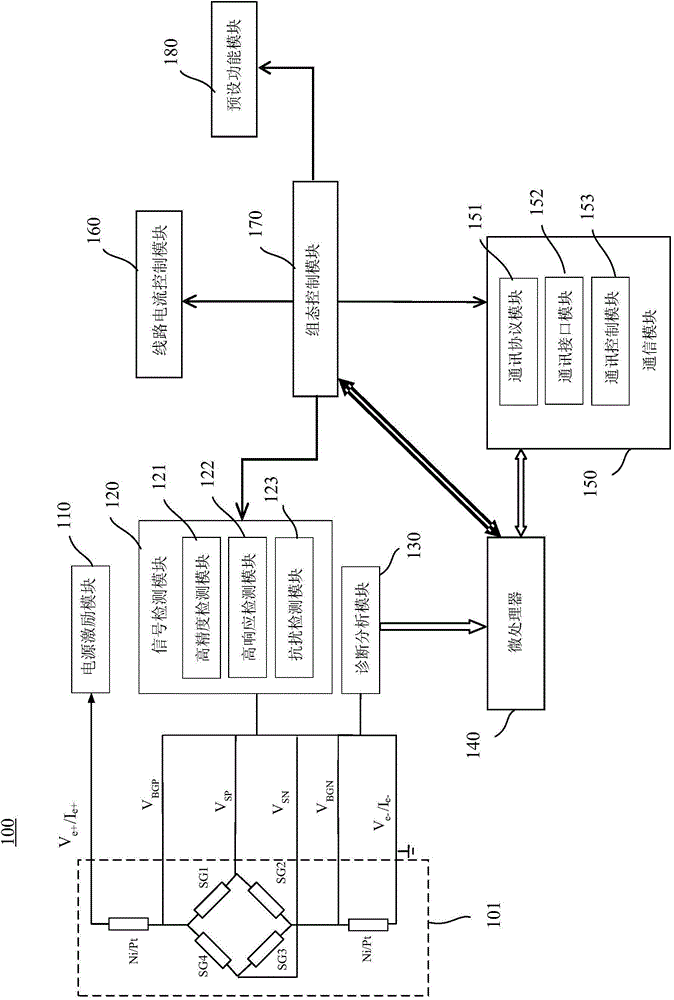

[0021] figure 1 A circuit block diagram of a configurable digital weighing sensor according to an embodiment of the present invention is shown. refer to figure 1 As shown, the digital load cell 100 includes a load cell 101, a power excitation module 110, a signal detection module 120, a diagnostic analysis module 130, a microprocessor 140, a communication module 150, a line current control module 160, a configuration control module 170 and Preset function module 180 .

[0022] The load cell 101 can detect the load force of the sensor and convert it into an electrical signal. The power excitation module 110 is connected to the load cell 101 to provide an excitation voltage for the load cell. A typical example of the load cell 101 is a resistive strain gauge. The resistive strain gauge is connected with the Ni / Pt resistance of the temperature sensing element according to the Wheatstone bridge principle, and the excitation voltage V of the power excitation module 110 is e+ / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com